Double-impeller self-rotation type fireproof mixer

A spin-type, mixer technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve problems such as poor mixing effect, uneven mixing, affecting the progress and effect of fire prevention and treatment, and achieves Excellent foaming and glue injection effect, low cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

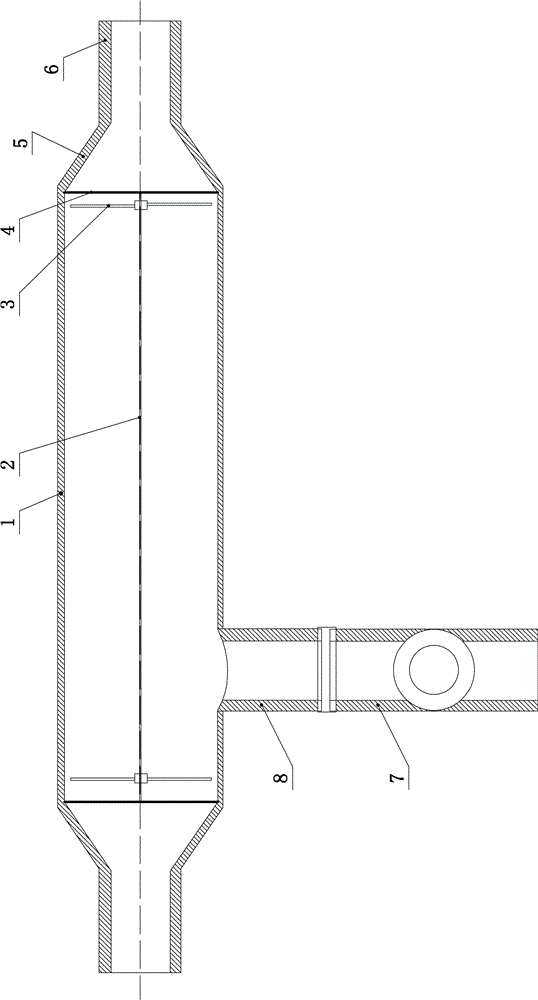

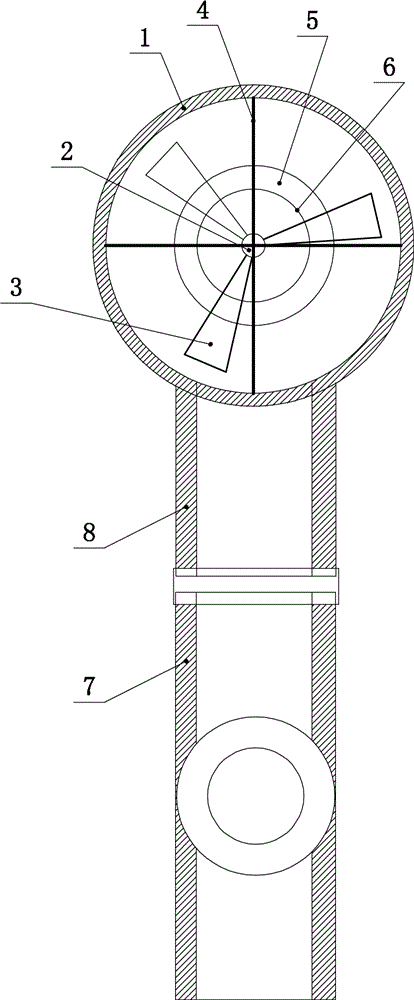

[0020] A double impeller spin fire mixer, such as figure 1 and figure 2 As shown, it includes a tee, and the tee includes a mixing pipe 1 and a connecting pipe 8 that communicate with each other. Two impellers 3 are connected to the mixing tube 1 for relative rotation, and the two impellers 3 are respectively located on both sides of the connecting point between the connecting tube 8 and the mixing tube 1;

[0021] In this embodiment, two impeller fixing frames 4 are fixedly connected to the front and rear of the mixing tube 1 , and the impeller shaft 2 is fixedly connected to the impeller fixing frame 4 , and the impeller 3 is relatively rotatably mounted on the impeller shaft 2 . The connection point between the connecting pipe 8 and the mixing tube 1 is 5-8 times longer than the proximal end of the mixing tube 1 from the far end of the mixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com