360-degree full-automatic cleaning ball

A technology for automatic cleaning and cleaning of balls, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of insufficient cleaning coverage, large size of rotating cleaning balls, and large consumption of cleaning liquid, etc. Achieve the effect of small consumption of cleaning fluid, strong cleaning ability and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

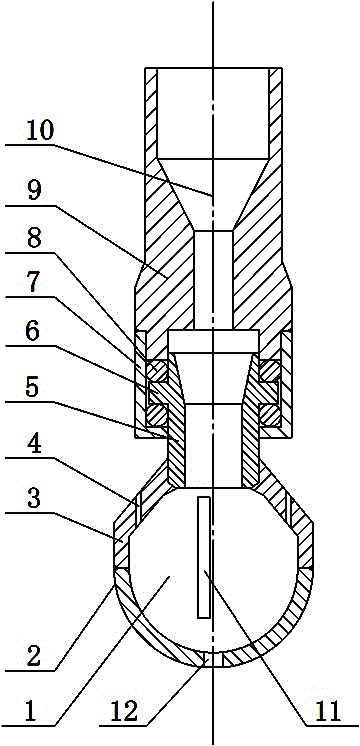

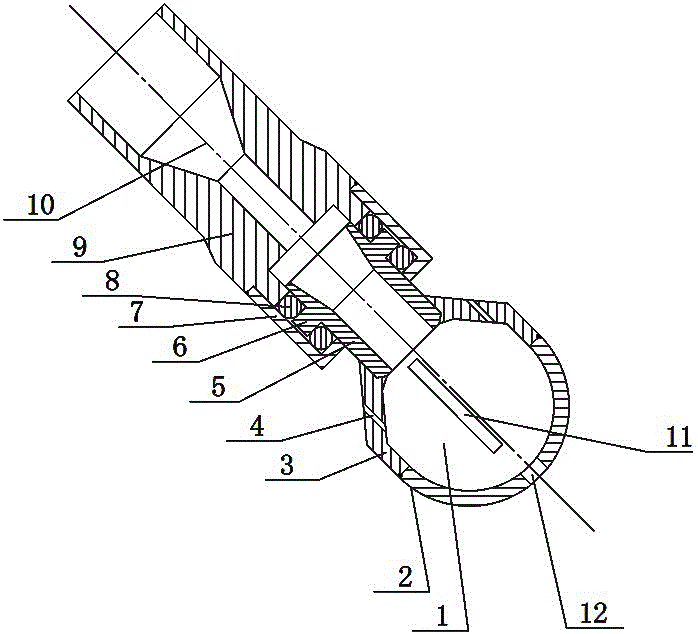

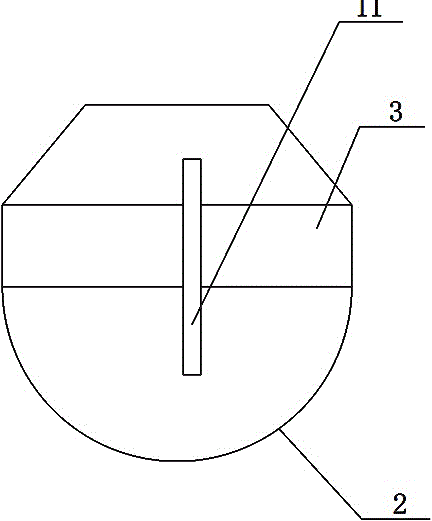

[0017] Such as Figure 1~Figure 5 As shown, the 360-degree fully automatic cleaning ball includes a cleaning ball 1, a rotating shaft 5, a bearing seat 7 and a connecting section 9, and the cleaning ball 1 is composed of an upper casing 3 and a lower casing 2 connected to the upper casing 3 Composition, the rotating shaft 5 is fixedly connected with the upper casing 3, and a plurality of asymmetric spraying grooves A4 are provided on the cleaning ball 1, part of the spraying grooves A4 is located on the upper casing 3, and a part is located on the lower casing 2, When the cleaning liquid quickly flows into the cleaning ball 1, because the spray tank A4 is asymmetrically arranged, when the water flows out of the spray tank A4, it will exert a tangential thrust on the cleaning ball 1, thereby pushing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com