Pulse welding equipment and control method thereof

A technology of pulse welding and control method, applied in welding equipment, arc welding equipment, metal processing equipment, etc., to achieve the effect of eliminating wire feeding overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

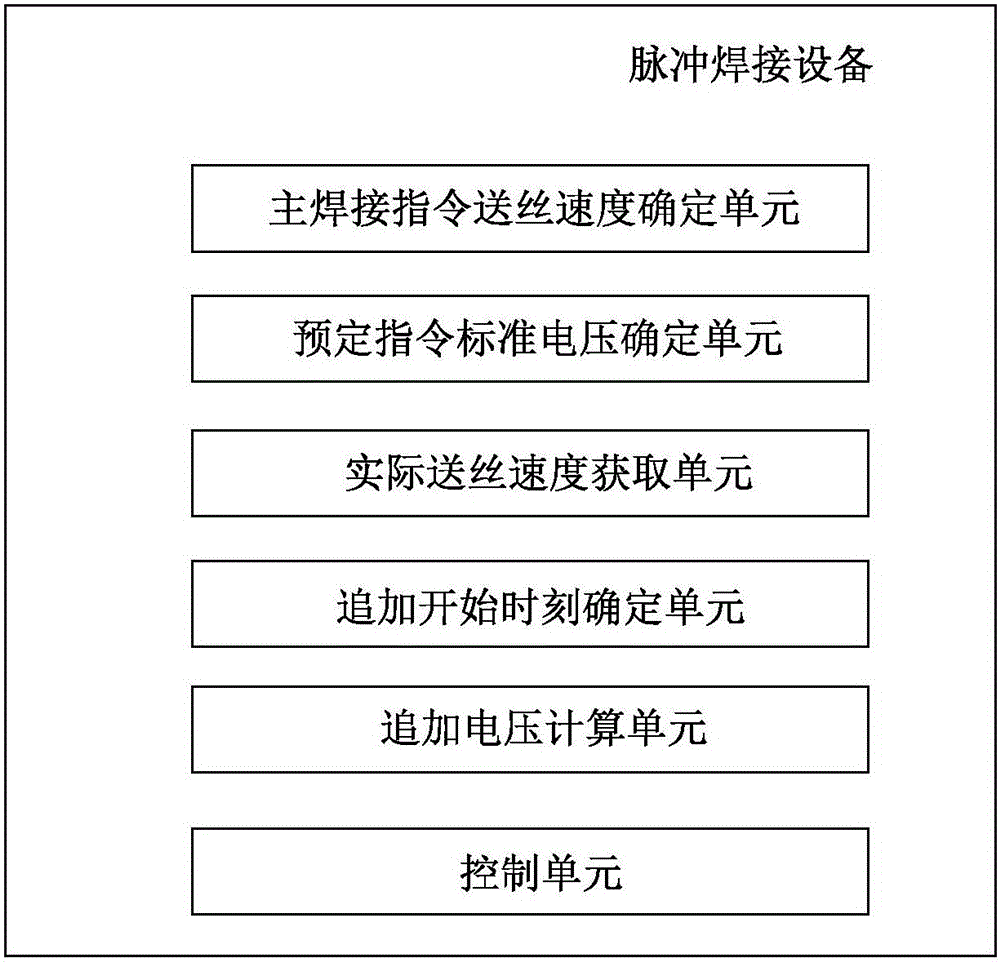

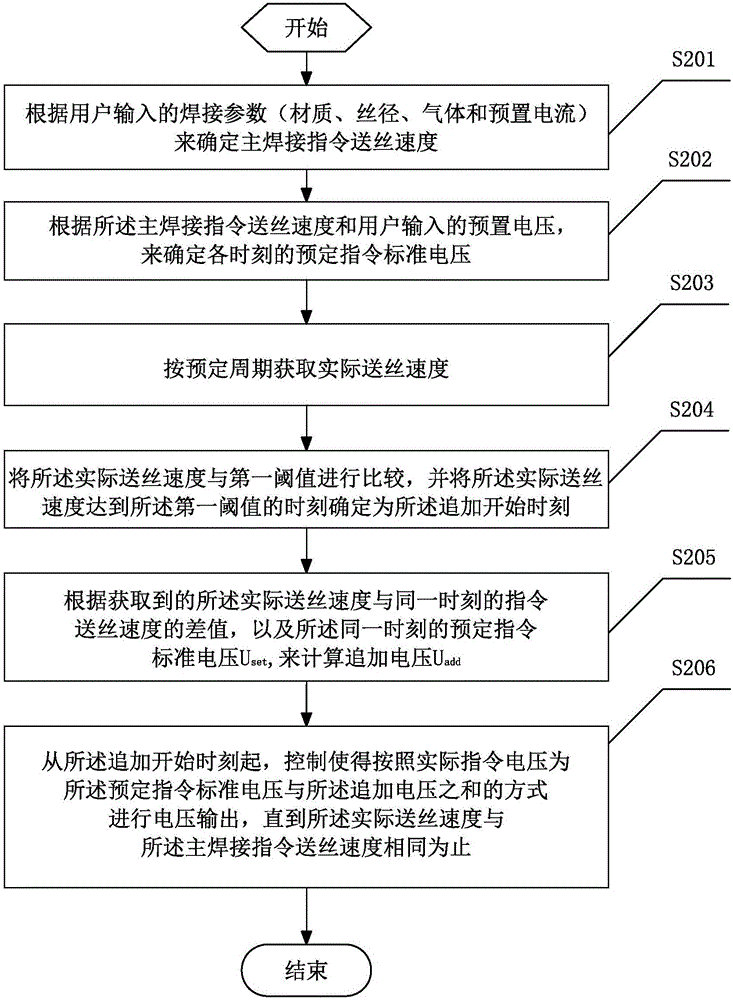

[0029] Refer below Figure 1 to Figure 3 A first embodiment of the present invention is described. figure 1 The software structure of the pulse welding apparatus of the first embodiment is shown.

[0030] Such as figure 1 As shown, the pulse welding equipment of the present invention includes: a main welding command wire feeding speed determination unit, which is used to determine the main welding command wire feeding speed according to the welding parameters (including material, wire diameter, gas and preset current) input by the user; The predetermined command standard voltage determination unit is used to determine the predetermined command standard voltage at each time according to the main welding command wire feeding speed and the preset voltage input by the user; the actual wire feeding speed acquisition unit is used to obtain the actual wire feeding speed according to a predetermined period wire feeding speed: an additional start time determining unit, configured t...

no. 2 example

[0045] Refer below Figure 4 and 5 A second embodiment of the present invention is described. Since the software configuration and control method of the second embodiment are basically the same as those of the first embodiment, the description will not be repeated here. Only the differences between the two are described below.

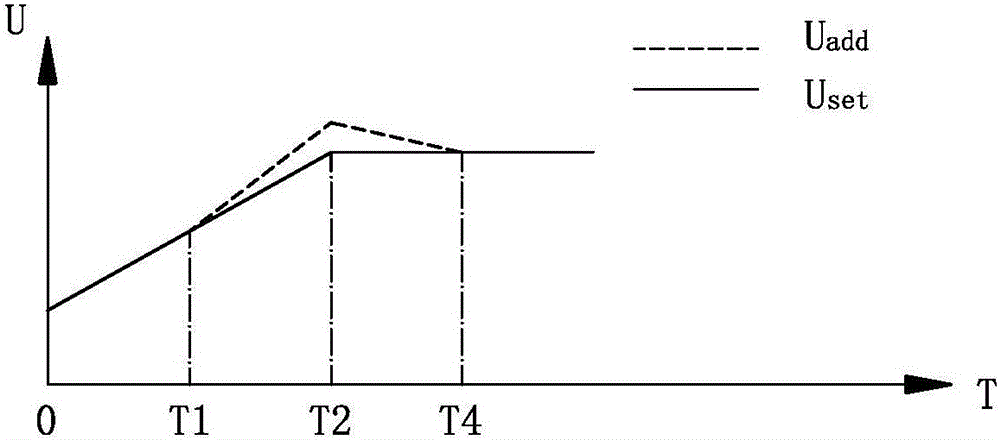

[0046] The second embodiment differs from the first embodiment in the control unit (ie, control step S406). In the second embodiment, step S406 is based on the step S206 of the first embodiment, and the following steps are added: at the time T2 (also called "holding time") from the command wire feed speed to the main welding command wire feed speed ), the CPU controls the voltage output in such a manner that the actual command voltage at the holding time is held for a predetermined period (the period of T2-T3).

[0047] After the predetermined period (the period of T2-T3) ends, the CPU controls to continue to carry out the voltage output according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com