Robot spraying device

A spraying device and robot technology, applied in spraying devices, manipulators, manufacturing tools, etc., can solve problems such as potential safety hazards, low efficiency, and inability to spray cylindrical molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings.

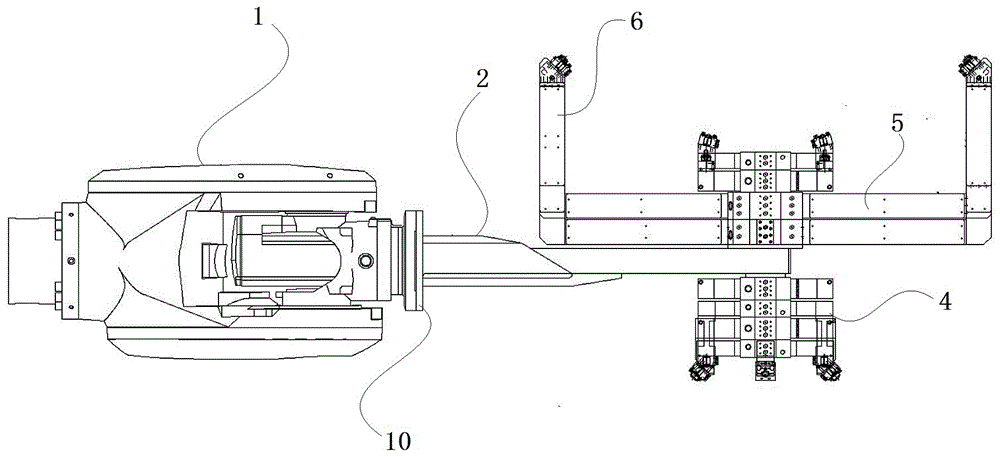

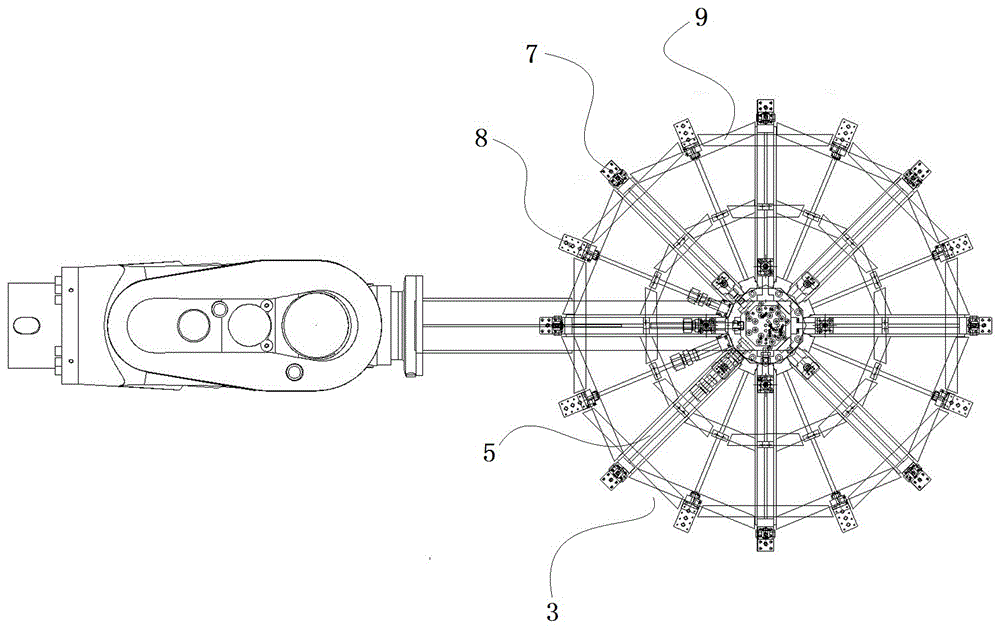

[0021] The invention discloses a robot spraying device, which is different from the prior art in that it includes a robot arm 1, which is connected to a circular bearing bracket 3 through a connecting rod 2, and the robot arm 1 and the connecting rod 2 are connected by a The flange 10 is connected, and a fixed block 4 is provided below the joint between the connecting rod 2 and the circular bearing bracket 3. There are several horizontal brackets 5 distributed from the center of the circle to the surroundings in the said circular bearing bracket 3. One end of the horizontal bracket 5 It is fixed at the center of circle of the circular support bracket 3, the other end of the horizontal bracket 5 is suspended, the suspended end of the horizontal bracket 5 is provided with a vertical bracket 6 vertically perpendicular to the horizontal bracket 5, and the lower end of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com