Deep sea pressure resistant device

A pressure-resistant device and deep-sea technology, applied in hydraulic engineering, artificial islands, underwater structures, etc., can solve the problems of poor hydrodynamic characteristics, sensitivity to defects, low space utilization, etc., and achieve good pressure resistance characteristics, good The effect of weight-to-strength ratio, reasonable material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

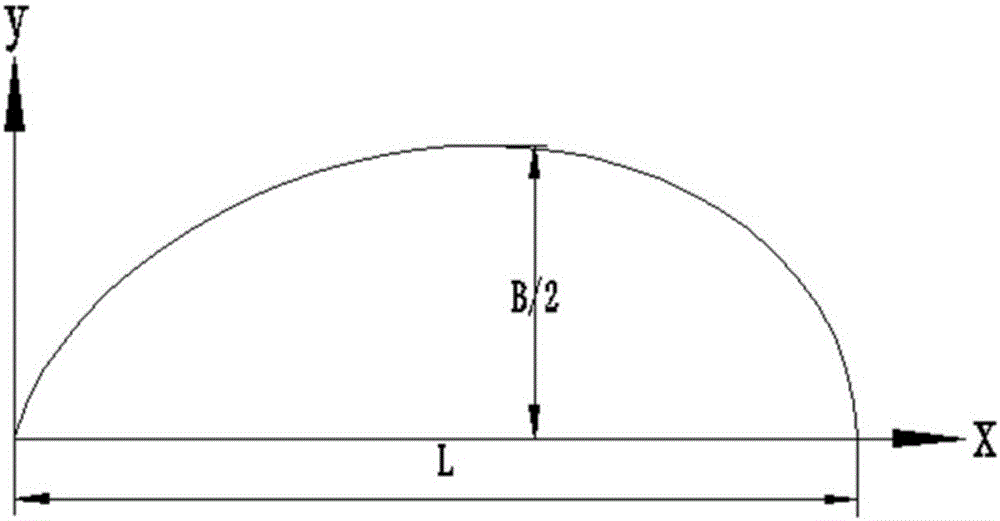

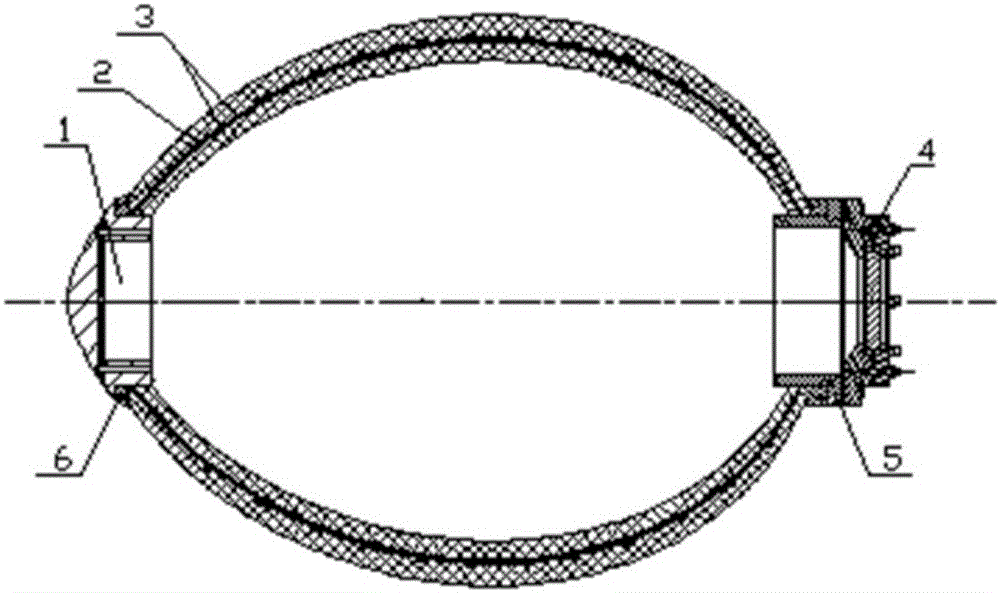

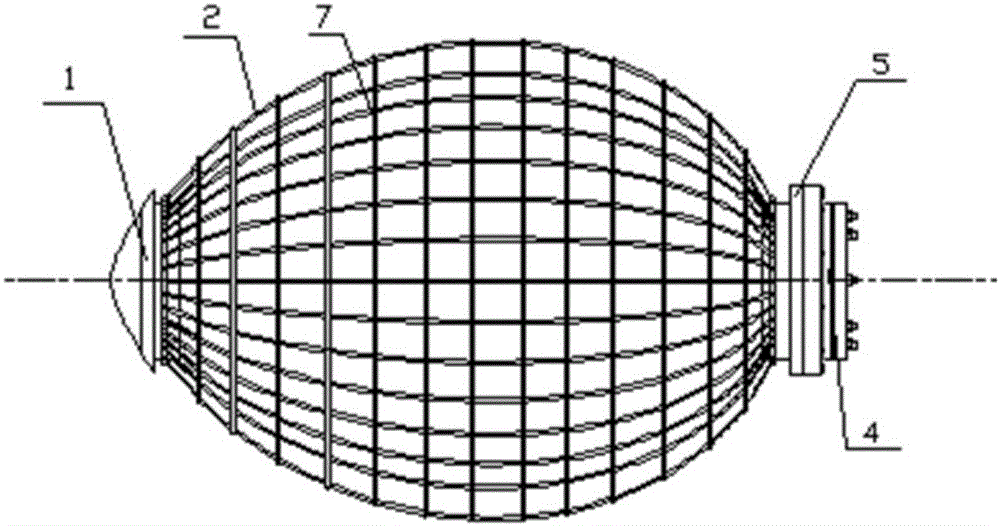

[0030] like Figure 2 to Figure 8 As shown, a kind of egg-shaped concrete pressure-resistant device 3 of the present invention comprises steel bar skeleton, and described steel bar frame is eggshell-shaped, and steel bar frame is symmetrical about the axis of pressure-resistant device, and the inner layer and outer layer of steel bar frame are all filled with Concrete 3, the two ends of the steel frame are the big end and the small end, and a manhole 1 is arranged on the big end and the small end, one end of the manhole 1 is connected with the manhole cover 8 through the gasket 9, and the other end of the manhole 1 is connected The mirror flange 5 is connected, the mirror flange 5 is connected with the mirror base 12 through the gasket 9, the mirror base 12 is equipped with a mirror glass 11, and the mirror glass 11 is fixed on the mirror base 12 through the compression ring 10 , the manhole 1 and the mirror flange 5 are connected to the concrete 3 . The thickness of the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com