Lifting method of wind turbine generator

A technology of wind turbines and hoisting methods, applied in wind power generation, installation/support of wind turbine configuration, wind turbine transportation, etc., can solve problems such as wind turbine instability and tipping, reduce offshore operations, reduce installation difficulty, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

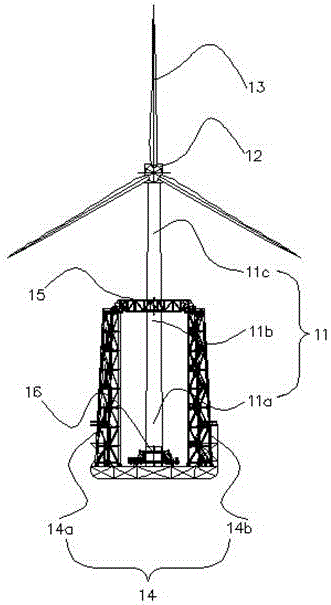

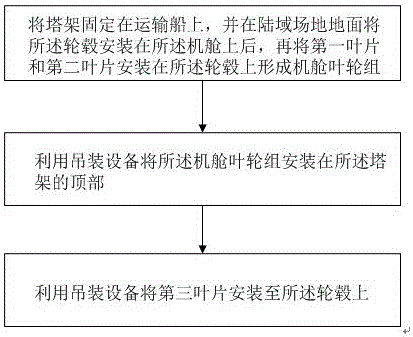

[0020] Such as figure 1 and figure 2 As shown, this embodiment provides a hoisting method for a wind turbine, wherein the wind turbine includes a tower 11, a nacelle 12 installed on the tower 11, and an impeller 13 installed on the nacelle 12, the The tower 11 is composed of a lower tower 11a, a middle tower 11b interconnected with the lower tower 11a, and an upper tower 11c interconnected with the middle tower 11b. The impeller 13 includes a hub and is installed on the The three blades on the hub, and the hub is installed on the nacelle 12, the hoisting steps are as follows: Step S1: Fix the tower 11 on the transport ship, and install the hub on the ground in the land area After the nacelle 12 is installed, the first blade and the second blade are installed on the hub to form a nacelle impeller set; Step S2: use a hoisting device to install the nacelle impeller set on the top of the tower 11; Step S3: The third blade is mounted on the hub using lifting equipment.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com