Repairing method for local defect of concrete in water level change region and repairing device

A technology for water level fluctuation areas and local defects, applied in water conservancy projects, water conservancy engineering equipment, buildings, etc., can solve problems such as not being effectively repaired, incomplete sealing around the formwork, repeated erosion of repair mortar, etc., to avoid premature Effects of erosion and soaking, reduction of offshore operations, and reduction of repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

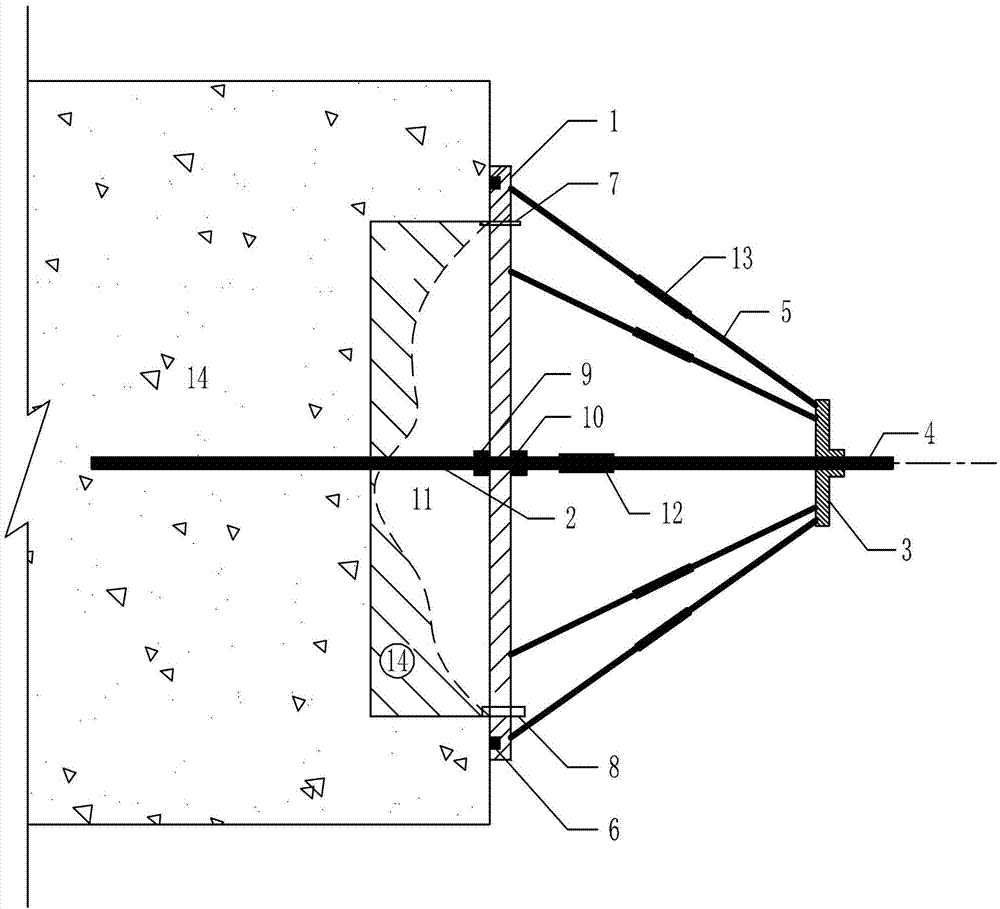

[0028] Referring to the accompanying drawings, a device for repairing local defects of concrete in a water level fluctuation area includes a formwork 1, a stainless steel expansion bolt 2, a diagonal brace support plate 3, a pull screw 4 and several diagonal rods capable of adjusting the length of the rod body. strut 5.

[0029] The above-mentioned formwork is used to cover the concrete defect cavity 11, and a water-swelling rubber strip 6 is provided around the inner surface of the formwork, such as a square ring-shaped groove is provided on the periphery of the inner surface of the formwork to stop The water glue strip 6 is arranged in the square annular groove. On the top of the formwork, there is an openable vent hole 7. For example, the vent hole can be equipped with a control valve to realize its opening and closing. When only the vent hole is provided, the vent hole can also be used as an air filling hole; of course, there are other The selection method, such as being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com