A design method of cross-sea steel immersed pipe

A design method and technology of immersed pipes, which are applied in the directions of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of unfavorable pipeline stability and structural safety, increase the difficulty and cost of protection, and friction of large-diameter immersed pipes. Large resistance and other problems, to achieve the effect of reducing the amount of offshore operations, reducing the number of offshore vessels, and reducing the area of the sea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention combines Figure 1-6 , to describe the design method of cross-sea steel immersed tube in detail, the method includes the following steps:

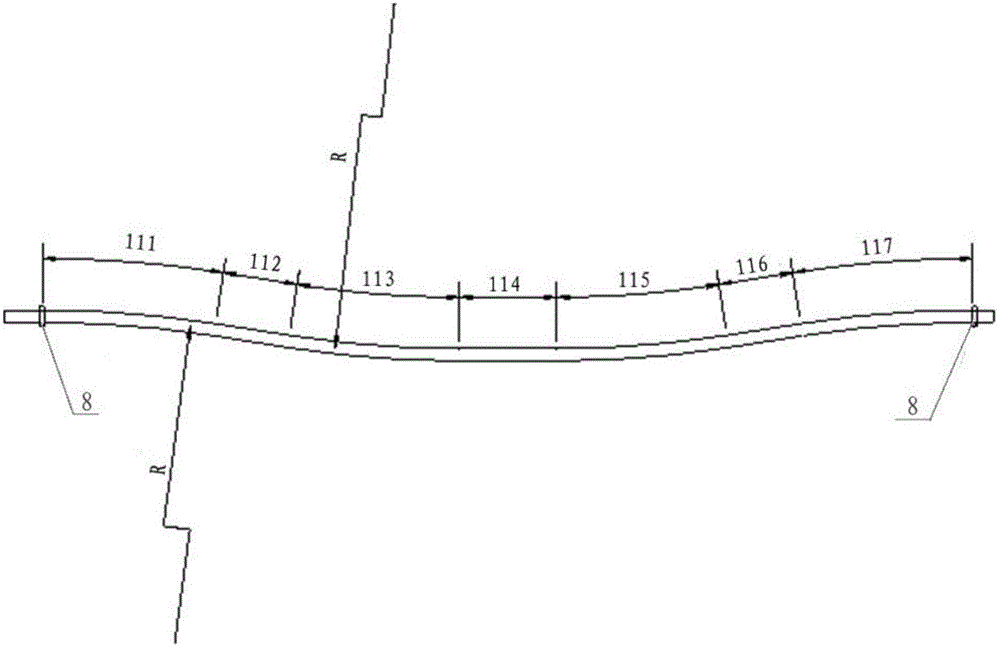

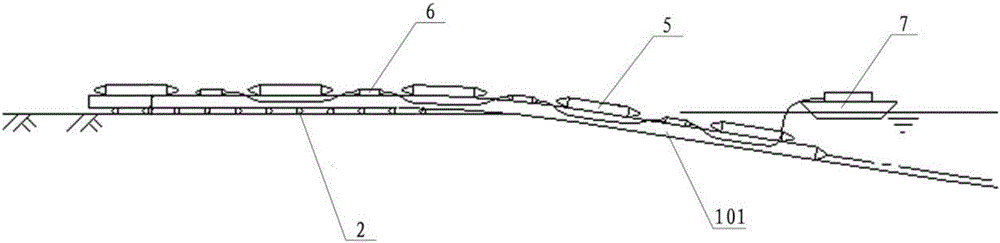

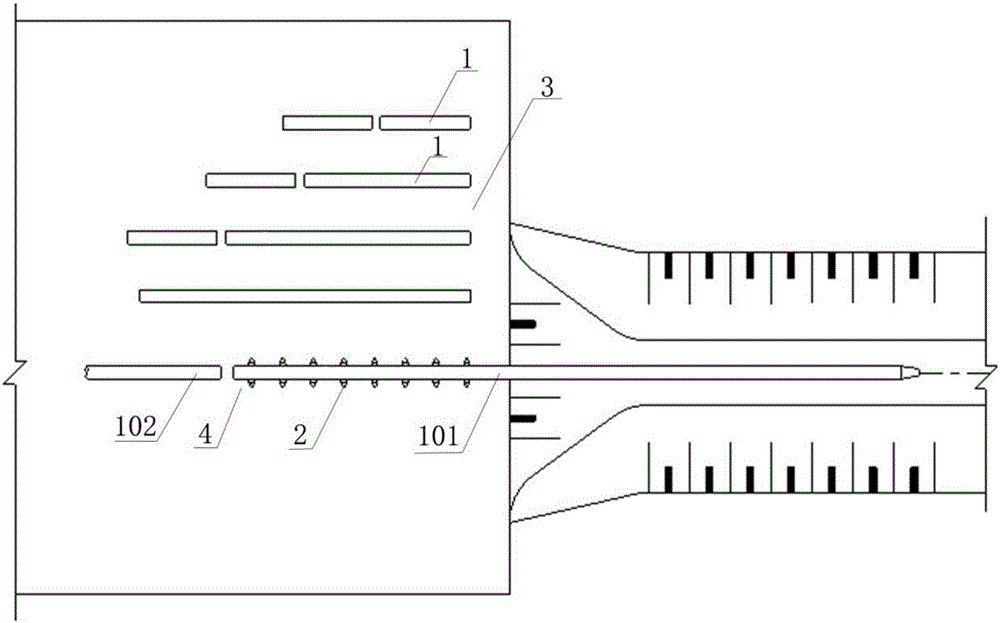

[0046] (1) if figure 1 As shown, according to the topography of the seabed, the pipeline layout of the sea-crossing steel immersed pipe with large diameter and super length-to-diameter ratio is determined mainly by the first downward bend section 111, the first straight pipe section 112, the first upward bend section 113, the second The straight pipe section 114, the second upward curved section 115, the third straight pipe section 116, and the second downward curved section 117 are sequentially connected to form. Wherein, the first lower bend section 111, the first straight pipe section 112, the first upper bend section 113, the second straight pipe section 114, the second upper bend section 115, the third straight pipe section 116 or the second lower bend section 117 All are welded and assembled by some steel pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com