Automatic closing device for gas pipe during cooling

A technology for automatic closing devices and gas pipelines, applied to valve devices, valve operation/release devices, heating fuel, etc., can solve problems such as flameout, flame extinguishing, and insufficient gas supply pressure, and achieve convenient operation, stable effect, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

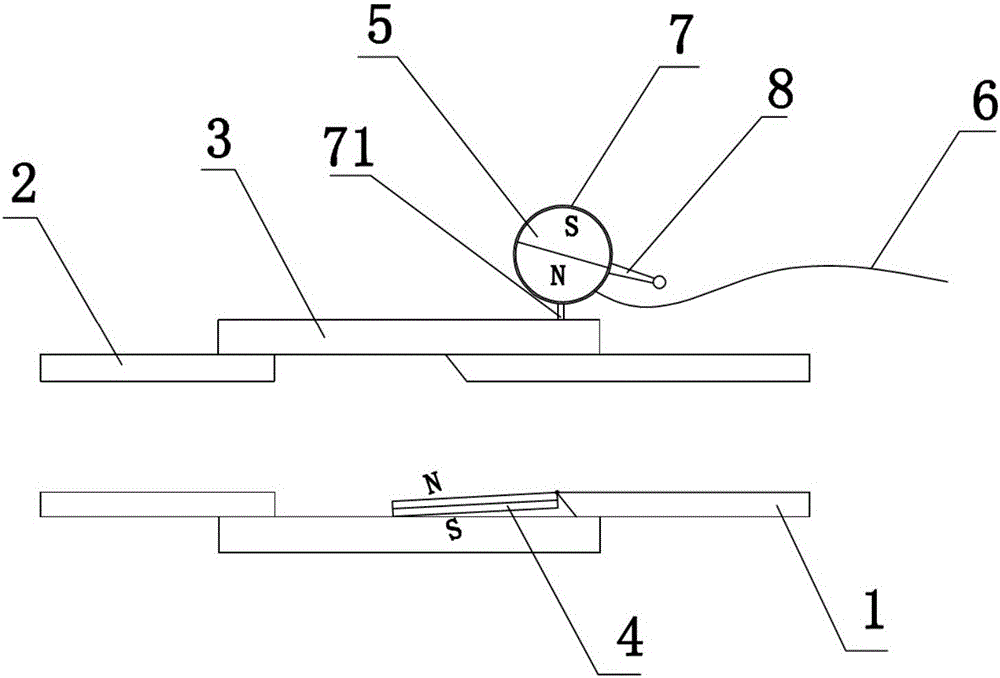

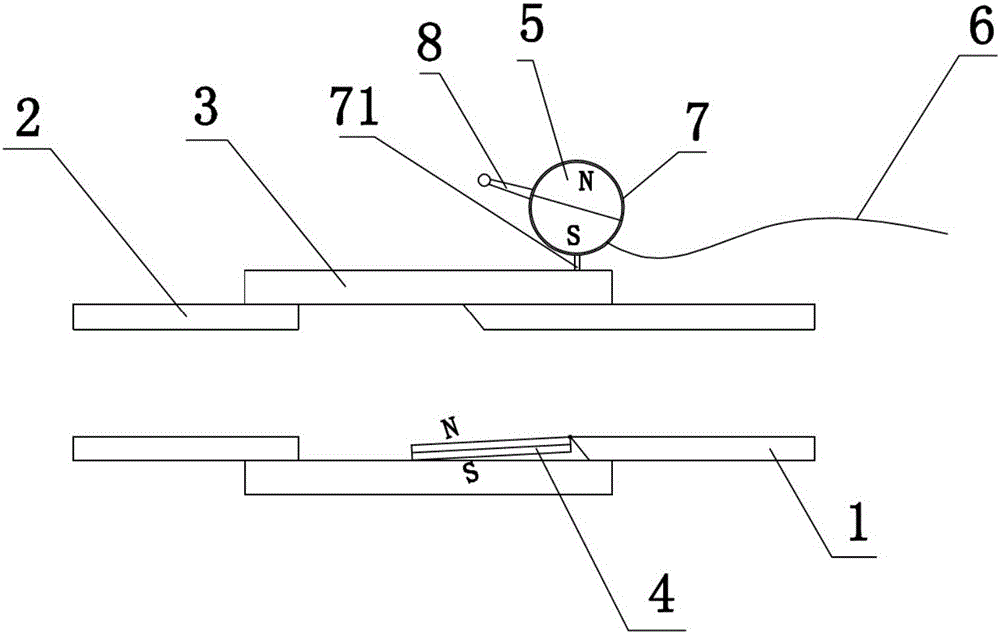

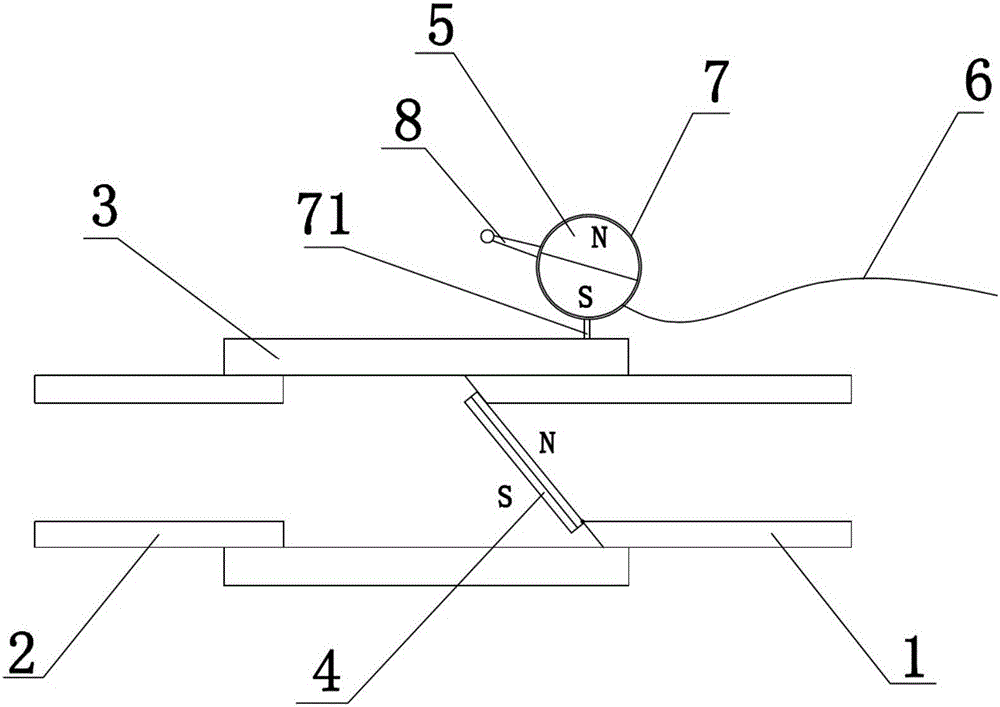

[0022] like Figure 1-4 As shown, the gas pipeline is automatically closed when the temperature drops, including a first gas pipeline 1 and a second gas pipeline 2, and a sleeve 3 is sealed between the first gas pipeline and the second gas pipeline. The lower inner wall at the port of the first gas pipeline in the pipe is hinged with a first magnet 4. The first magnet is a valve for closing the first gas pipeline. The magnetic poles of the first magnet are located at the upper and lower ends respectively; A second magnet 5 is provided, and the second magnet is located above the first magnet at the same time, and the magnetic poles of the second magnet are also located at the upper and lower ends respectively, and the second magnet can be flipped up and down. The opening of the first gas pipeline is an oblique section, and the oblique section faces downward, which is convenient for the first magnet to close the first gas pipeline.

[0023] The second magnet is a nickel-iron al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com