Metal-glass directly-sealed type solar high-temperature heat collecting pipe

A solar energy and heat collecting tube technology, which is applied in the field of metal-glass direct-sealed solar high temperature heat collecting tubes, can solve problems such as affecting the heat collecting efficiency of the heat collecting tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

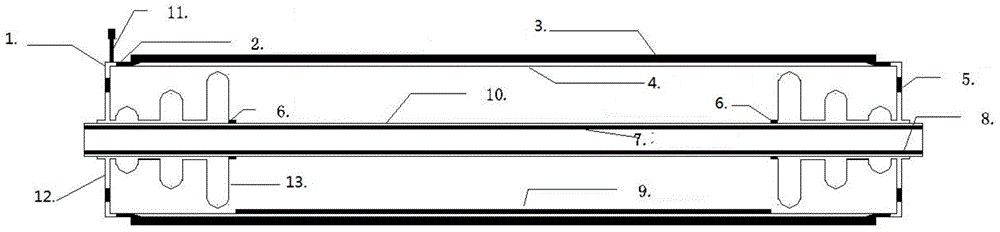

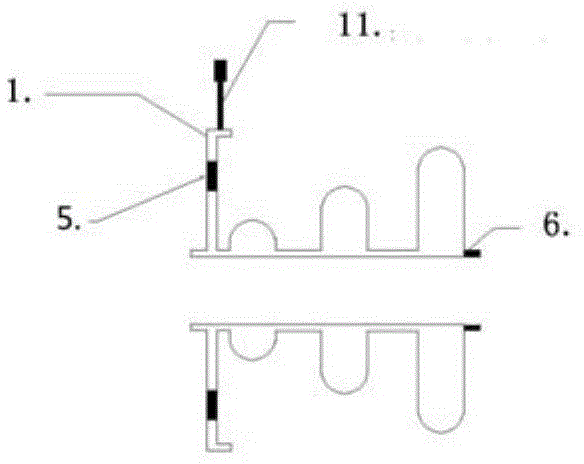

[0015] The specific embodiment of the solar vacuum heat collecting tube of the present invention is as follows: figure 1 As shown, the stainless steel coated inner tube 7 is inserted into the glass outer tube 4, and the two ends of the glass outer tube are respectively sealed with a metal-glass sealing gold ring 2, and the metal-glass sealing gold ring 2 is connected to the glass outer tube 4. The expansion compensator 1 is welded to form a vacuum cavity; the expansion compensator 1 is equipped with a hydrogen permeable material 5 and a long-term getter 6; on the inner wall of the stainless steel coated inner tube 7, a hydrogen barrier coating 8 is prepared, A heat-absorbing coating 10 is prepared on the outer wall of the stainless steel-coated inner tube 7 ; an anti-reflection film 3 is prepared on the outer wall of the glass outer tube 4 , and a reflective film 9 is prepared on the inner wall of the glass outer tube 4 .

[0016] When in use, the heat-collecting medium flows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com