Integrated fireproof rolling door section mill

An integrated, fire-resistant material technology, applied to fire doors, shutters/movable grilles, etc., can solve the problems of increasing spot welding equipment, high labor intensity, and increasing investment costs, so as to ensure product quality, reduce the number of workers, The effect of saving installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

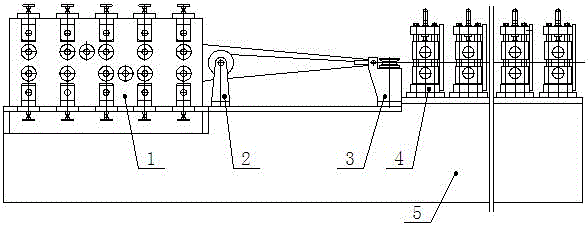

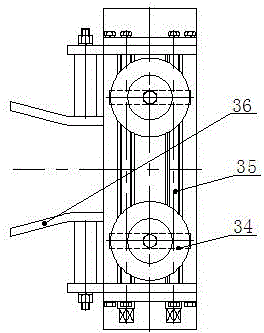

[0023] Such as Figure 1 ~ Figure 3 As shown, the integrated fire-resistant rolling door profile rolling mill includes a double-layer preliminary rolling sheet-shaped rolling mill 1, a fireproof material coil rack 2, a joint positioner 3, a hinged rolling mill 4 and a base 5. The double-layer preliminary rolling sheet rolling mill 1, the fireproof material coil stand 2, the lamination positioner 3 and the hinge coil rolling mill 4 are successively installed on the base 5 along the profile moving direction.

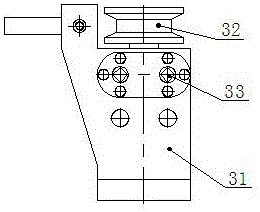

[0024] The double-layer preliminary rolling sheet-shaped rolling mill 1 is located at the feed end of the integrated fireproof rolling door profile rolling mill. It includes four rows of rolls up and down. Figure 5 The lower part of the middle); the upper two rows of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com