Thread self-locking type tool fixture for rectangular workpiece

A tooling fixture and self-locking technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of large size of automatic clamps, high requirements for machining accuracy, and high cost of use, and achieve simple and compact structure and high machining accuracy. The effect of low requirements and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

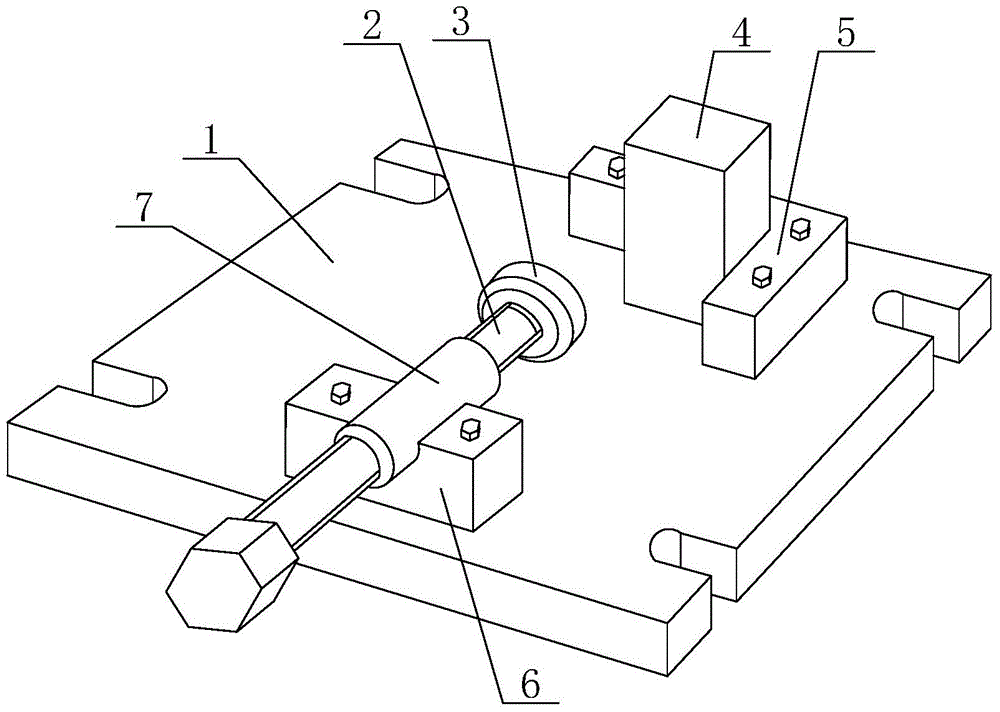

[0021] Such as figure 1 A threaded self-locking rectangular workpiece tooling fixture shown includes a rectangular bottom plate 1 with opening installation grooves symmetrically arranged on both sides, and an L-shaped positioning block 5 for positioning and supporting the workpiece 4, and the L-shaped The positioning block 5 cooperates with the disc-shaped indenter 3 for compressing the workpiece 4, the drive screw 2 for driving the disc-shaped indenter 3 to move back and forth, and the drive screw 2 matched to form a threaded transmission pair The threaded sleeve 7 and the support 6 for installing the threaded sleeve 7; the upper side of one end of the rectangular bottom plate 1 is fixed with the L-shaped positioning block 5, and the other end of the rectangular bottom plate 1 A support 6 is fixedly installed on the side, the threaded sleeve 7 is fixedly installed on the support 6, the drive screw 2 is arranged inside the threaded sleeve 7, and the inner end of the drive scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com