Cutter protective sleeve

A technology for protective sleeves and knives, which is applied in the manufacture of tools, grinding/polishing hand tools, metal processing, etc. It can solve the problems of easy rusting of knives, threats to the elderly and children, and potential safety hazards, so as to prevent the knives from rusting, The effect of avoiding direct contact and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

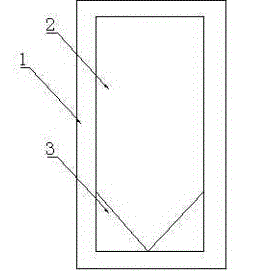

[0013] Example: such as figure 1 A tool protection sleeve 1 is shown. The tool protection sleeve 1 is in the shape of a scabbard with an open end. The tool protection sleeve has a hollow cavity 2 that matches the body of the tool. A whetstone layer 3 is provided at a position corresponding to the blade edge of the knife.

[0014] The cross section of the whetstone layer 3 is V-shaped.

[0015] The whetstone layer 3 is adhered to the knife protective sleeve 1.

[0016] When the knife is not in use, it is only necessary to wipe it clean and put the knife body into the knife protective cover 1, and then store it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com