Novel plastic circular weaving machine

A circular loom, a new type of technology, applied to circular looms, looms, textiles, etc., can solve the problems affecting the quality of material processing, high main engine speed, heavy load of the balance wheel, etc., so that it is not easy to fluff and break, and improves work efficiency , Guarantee the effect of weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

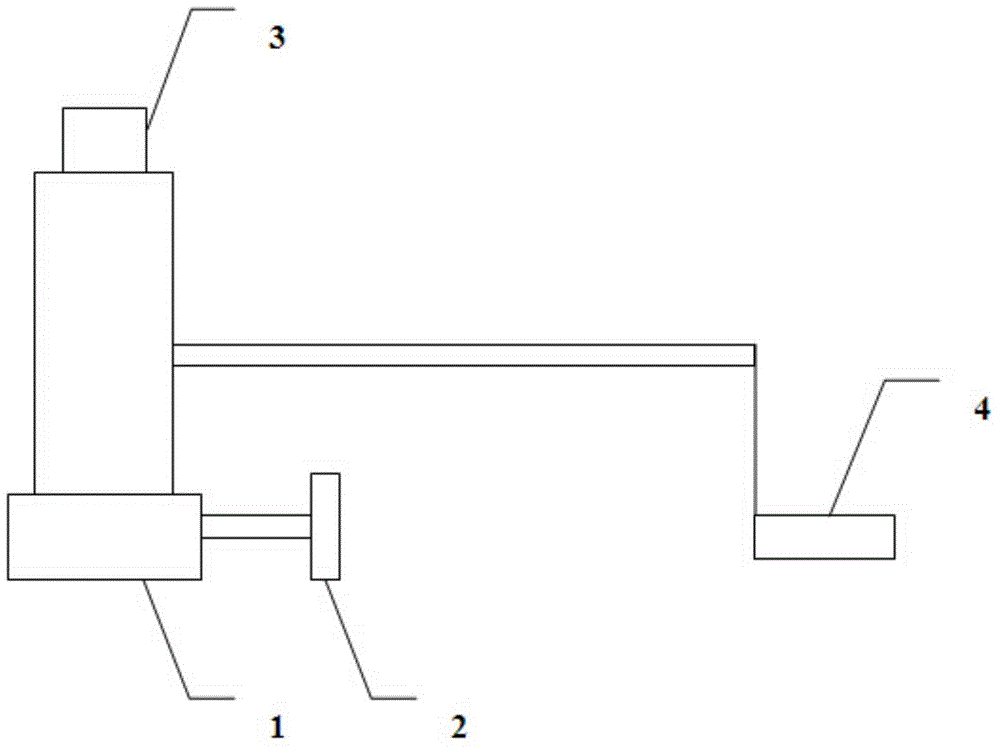

[0013] The present invention is a novel circular loom, comprising a main machine 1 , a let-off device 2 , a cloth lifting device 3 and a cloth rolling device 4 . The main machine is placed on the top of the platform, and the platform is a hexagonal structure, and the warp frame is connected to the outside. The main engine contains a transmission system inside, and a speed regulating device is arranged in the transmission system, and the speed regulation motor can be connected through the controller to realize the adjustment of the running speed. 10 shuttles are installed in the main frame, which can realize large-diameter weaving. The warp let-off device includes a warp let-off bracket and a warp let-off roller. The warp let-off roller is arranged on the warp let-off bracket, and one end of the warp let-off roller is connected to a driving device, and the other end of the warp let-off roller is fixed with a brake wheel. The main machine is connected with six let-off devices 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com