Yarn pressing device of computer flat-knitting machine

A flat knitting machine and yarn pressing technology, applied in the directions of knitting, weft knitting, textiles and paper making, etc., can solve the problems of unseen, floating yarn and scrapping, etc., and achieve the effect of ensuring the quality of knitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

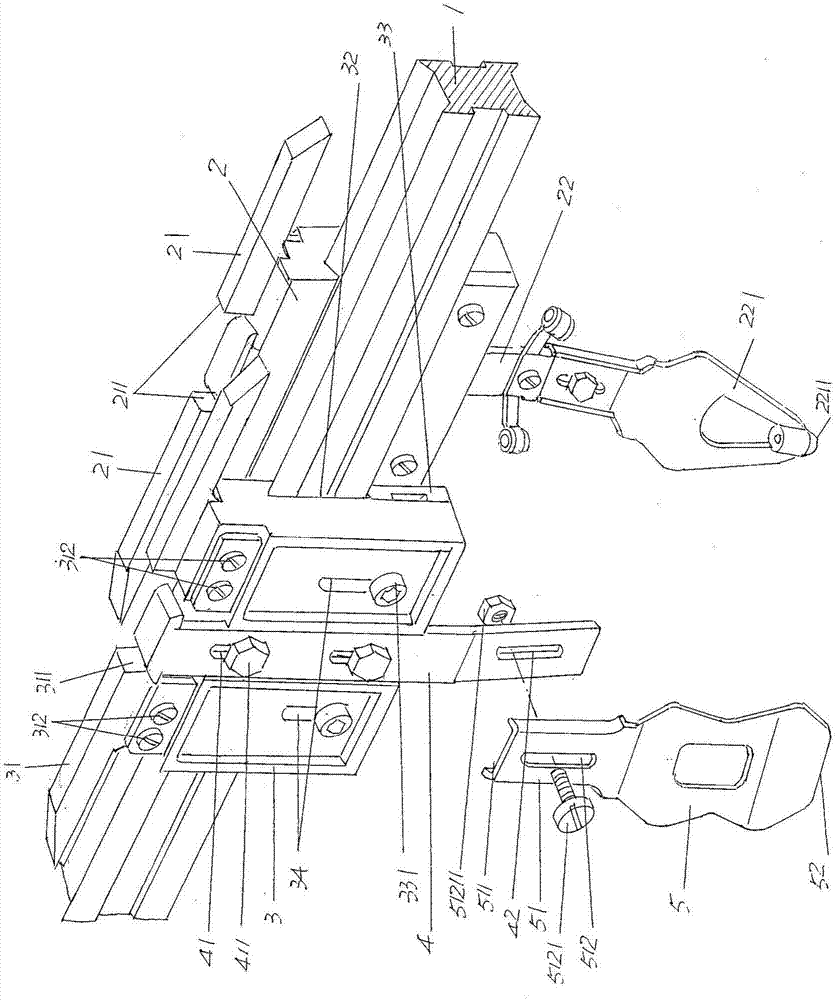

[0017] See figure 1 , shows the guide rail 1 (also called "yarn feeder guide rail") of the structural system of the computerized flat knitting machine and the yarn feeder seat 2 arranged on the guide rail 1 to move left and right, and a pair of yarn feeder seats 2 are fixed on the upper part The yarn feeder seat contact feet 21 with opposite directions to each other, the space between the pair of yarn feeder seat contact feet 21 constitutes a shuttle changing slider cavity 211, and there is a yarn feeding feeder guide rod 22 at the bottom of the yarn feeder seat 2. A yarn feeding feeder 221 is fixed at the bottom of the yarn feeder guide rod 22 . Since this structure of the computerized flat knitting machine belongs to the known technology, for example, please refer to CN201305729Y (yarn feeder seat), so the applicant will not repeat it here.

[0018] As the technical points of the technical solution provided by the present invention: the yarn pressing device provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com