Patents

Literature

36results about How to "Guaranteed weaving quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure resisting Silicon rubber hose and its mfg. method

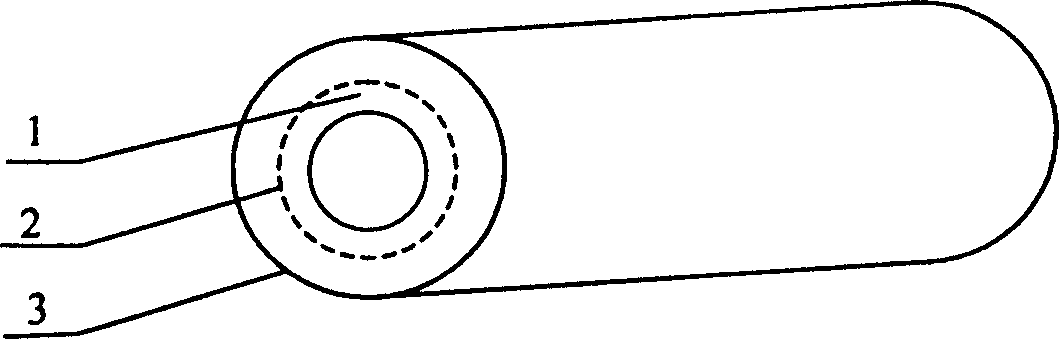

A pressure silicon rubber hose and its manufacture method adapted for use in food and pharmaceutical industries comprises an inner rubber layer, a fibre-braided reinforcement and an outer rubber layer. The main material of the inner and outer layers is silicon rubber. The inside diameter of the inner rubber layer after prevulcanizing process is phi 8~25 mm and the thickness is 2~4 mm. The prevulcanizing can carry out in a hot-air drying tunnel or in a water bath vulcanizing bank.

Owner:上海尚翔汽车胶管有限公司

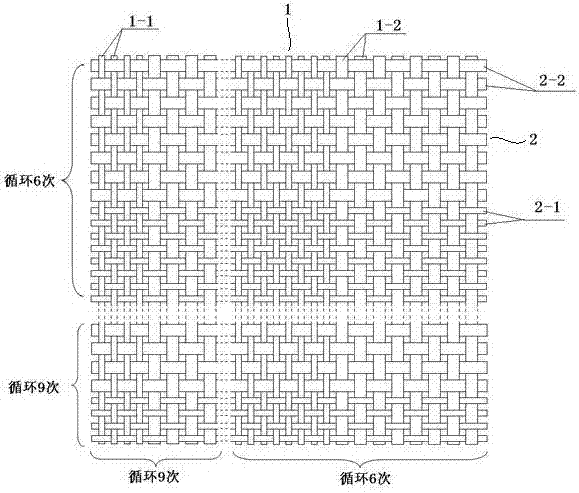

Plisse crepe lattice fabric production technology

ActiveCN107488927ASolve the impossible to weave puzzleReduce weaving costHeating/cooling textile fabricsDry-cleaning apparatus for textilesEngineeringDyeing

The invention discloses a plisse crepe lattice fabric production technology which is characterized by comprising the following steps: evenly winding first warps and second warps on a warp beam through a warping technology, wherein warps include the first warps and the second warps, and the first warps and the second warps have different warp tensions; utilizing a single warp beam weaving technology to weave gray fabric of the plisse crepe lattice fabric; finishing through a later dyeing and finishing technology to enable the shell fabric to not only form grid shape distribution Plisse crepe lattice fabric with a unique style, but also have good all-side stretch touch of shell fabric. According to the seersucker grid shell fabric production technology disclosed by the invention, the technologies of warping, re-beaming, weaving, desizing, scouring, bleaching and the like are innovated, so that the problem that single warp beam weaving cannot weave plisse crepe is solved.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

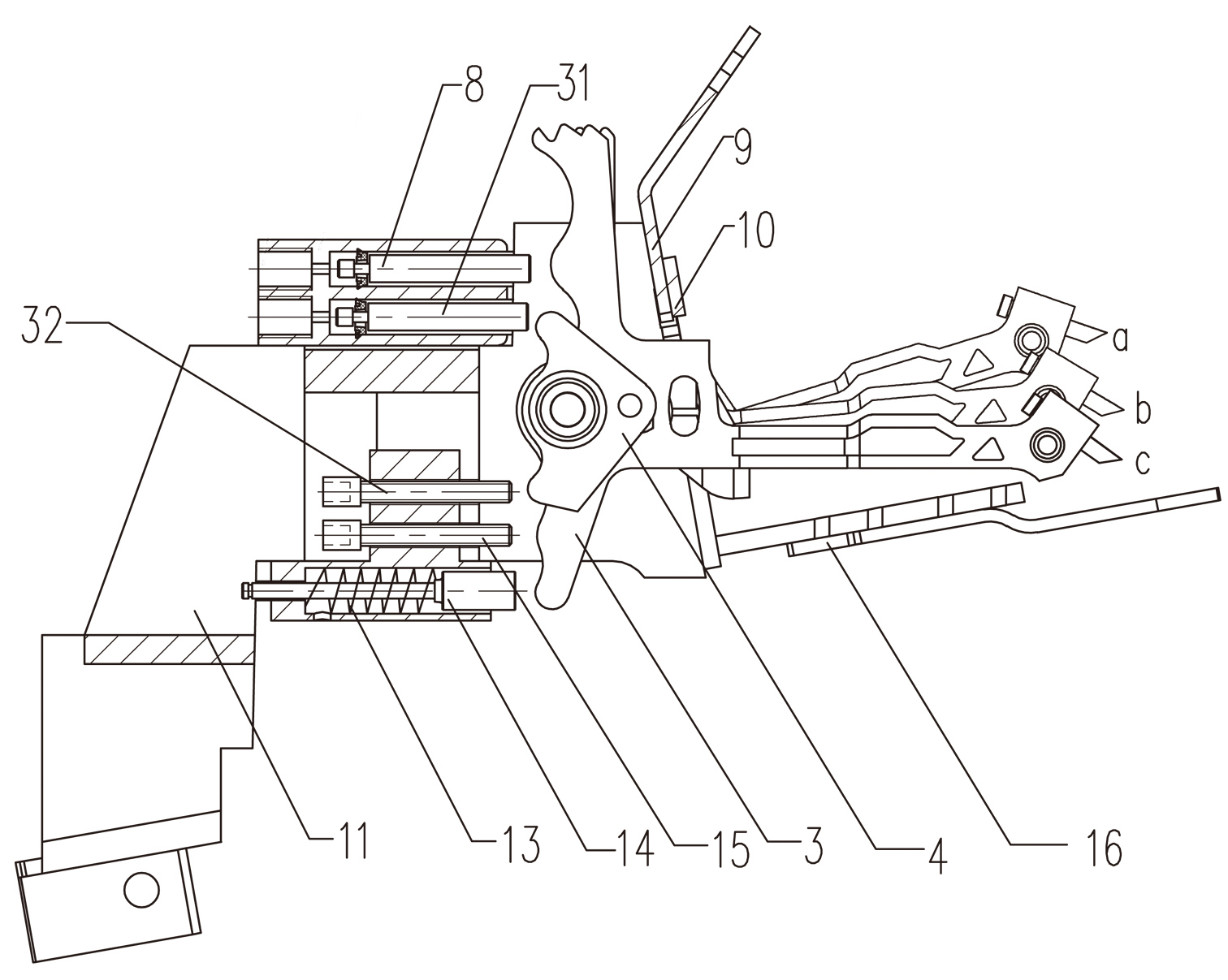

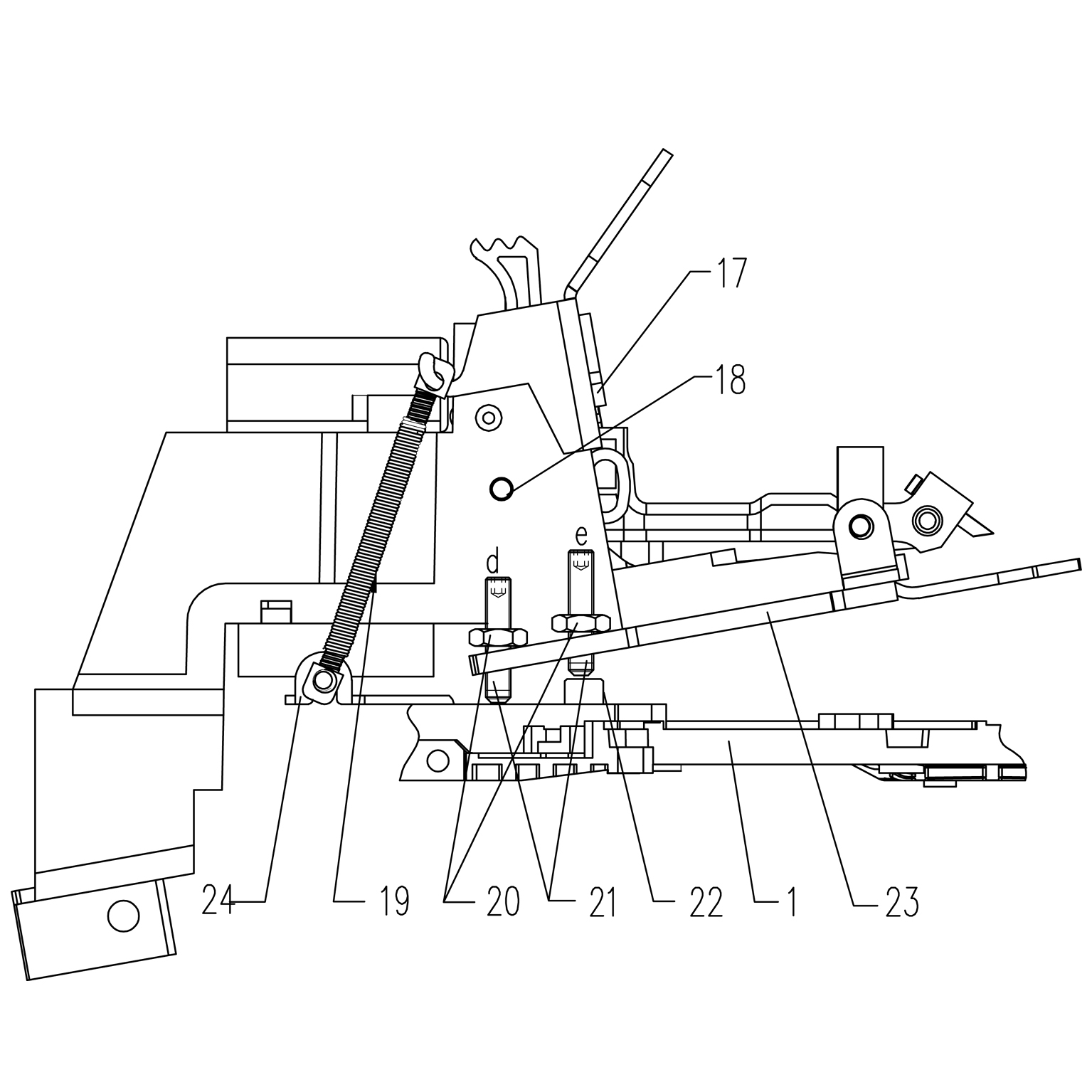

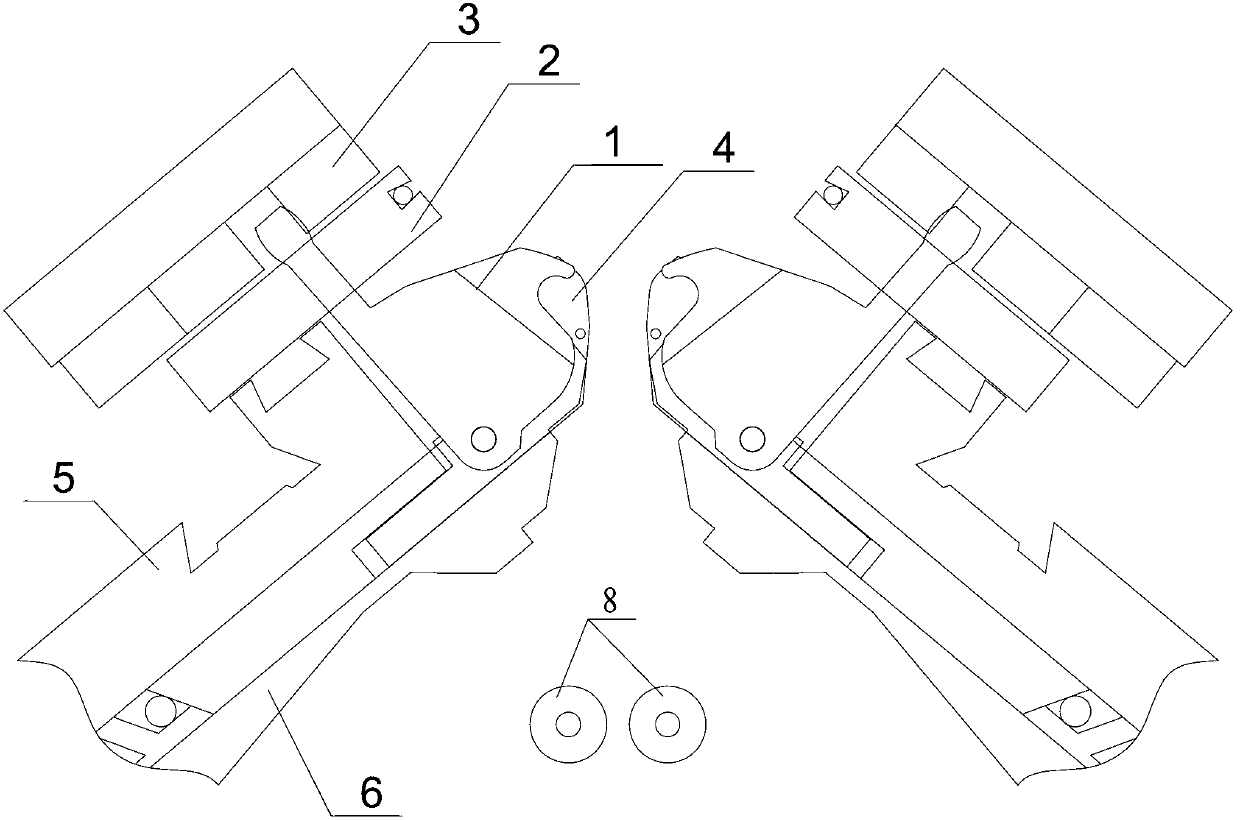

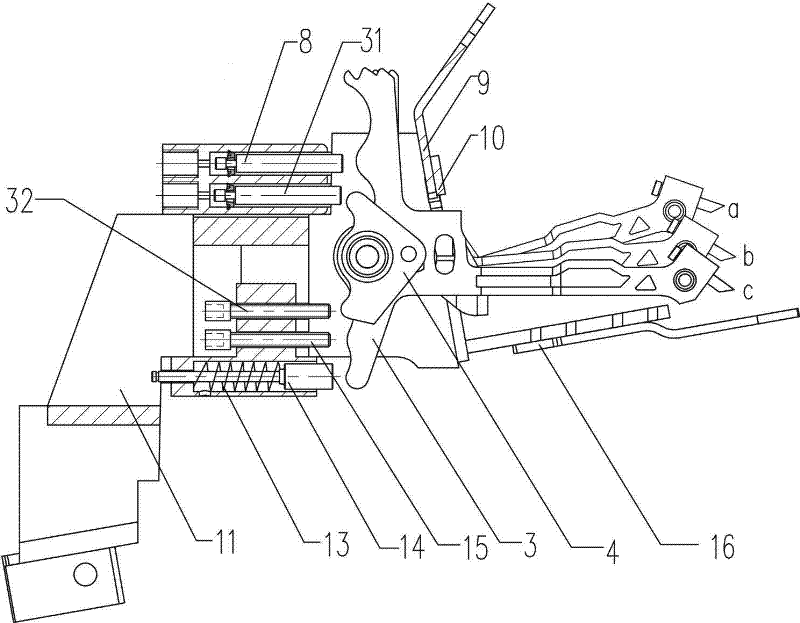

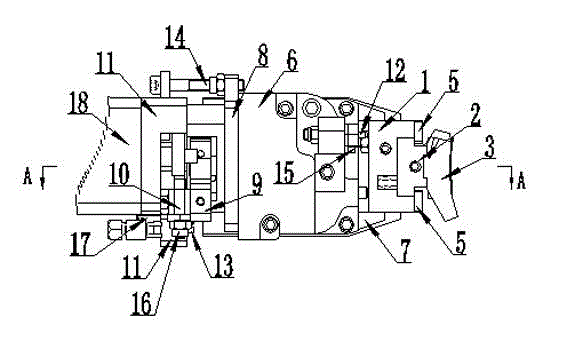

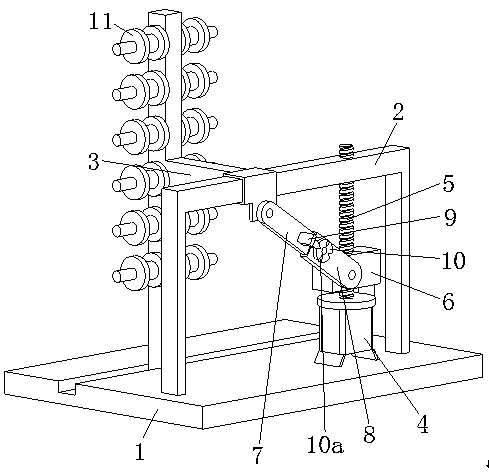

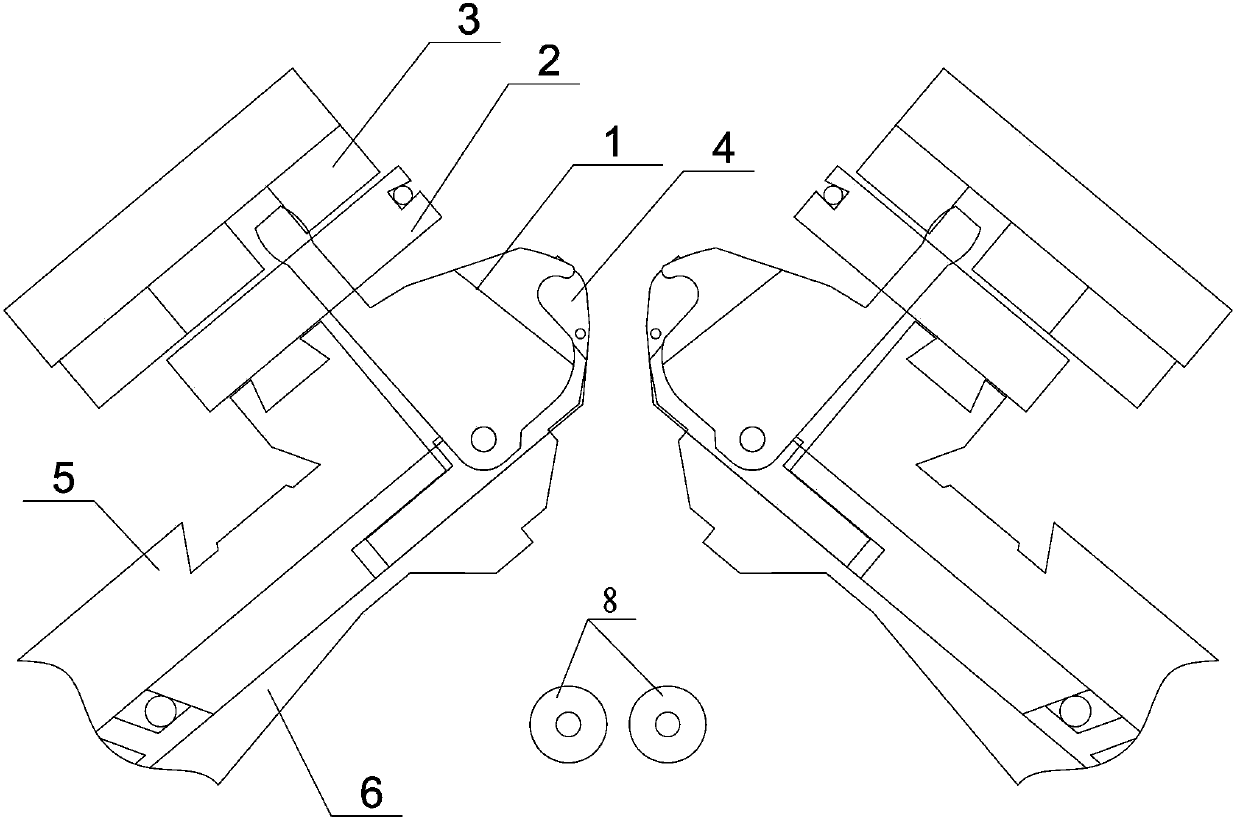

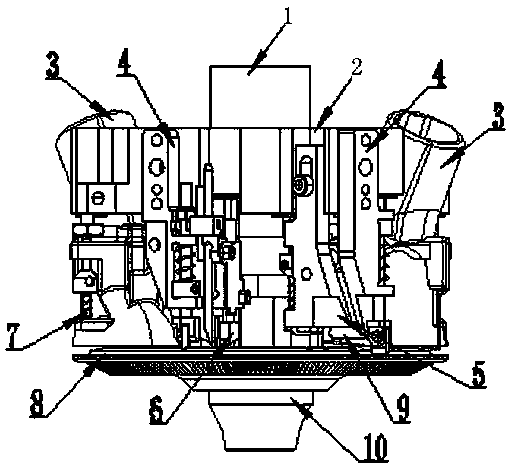

Yarn feeding device of computer silk stockings machine

ActiveCN101994207AReach the function of limit adjustmentPrevent closing and decouplingWeft knittingYarnState of art

The invention discloses a yarn feeding device of a computer silk stockings machine, which comprises a shuttle cylinder body and multiple yarn feeding shuttles, wherein the shuttle cylinder body is provided with multiple first cylinder pistons and push rods with springs; the multiple yarn feeding shuttles are axially connected to the shuttle cylinder body through cylindrical hinge pins; the tail part of each yarn feeding shuttle respectively corresponds to one first cylinder piston and one push rod with the spring, and the cylinder pistons and the push rods with the springs are matched; the shuttle cylinder body is also provided with multiple second cylinder pistons; and the tail part of each yarn feeding shuttle respectively corresponds to one second cylinder piston and is matched with the corresponding second cylinder piston. Compared with the existing technique, the yarn feeding device enhances the use performance of the computer silk stockings machine and the stability in the knitting course, solves the problems of incorrect yarn feeding and low relevant speed in the existing technique, guarantees the knitting quality of the product, enhances the working efficiency and can satisfy the marketization requirements by adopting the technical scheme.

Owner:NINGBO CIXING

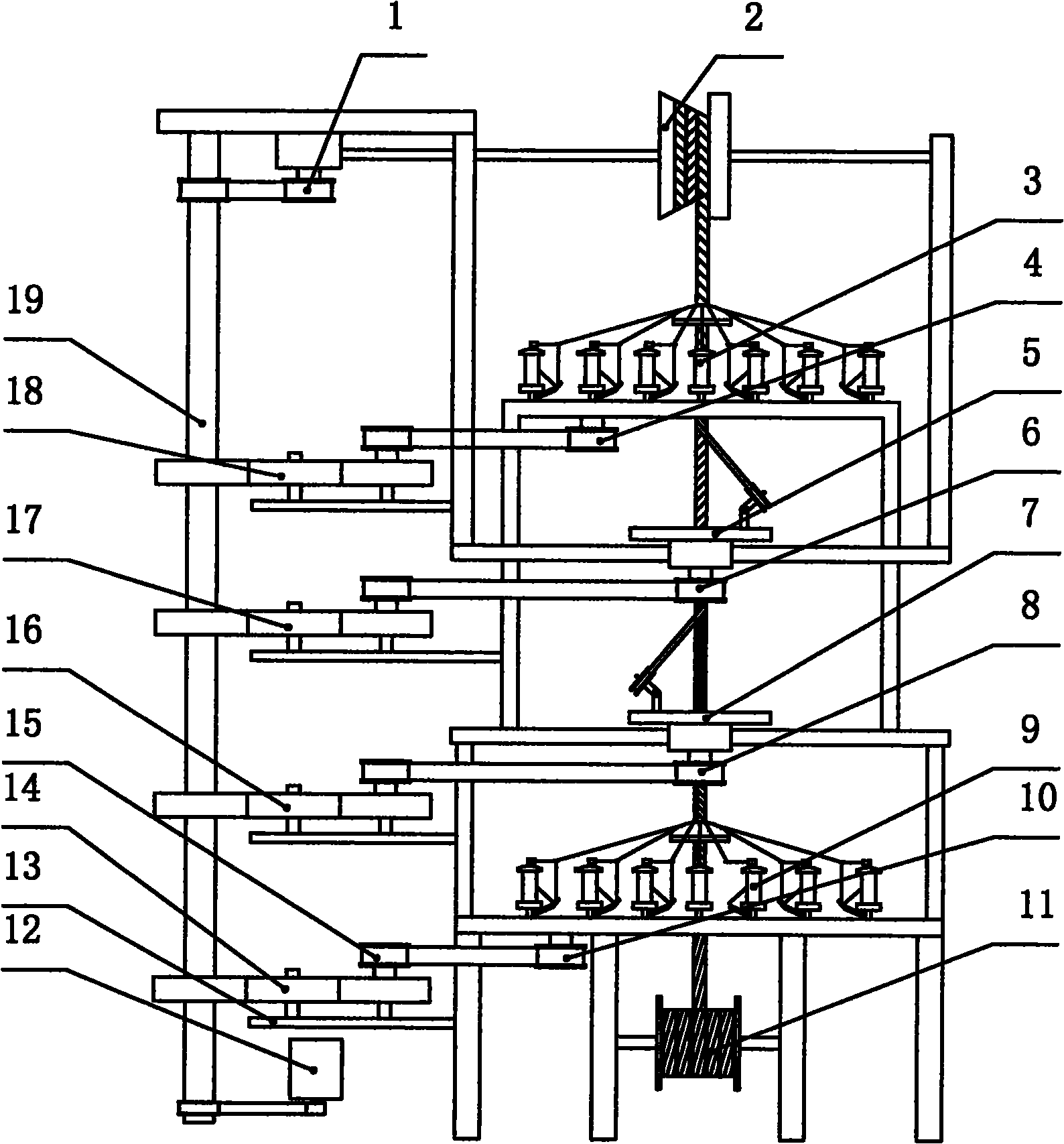

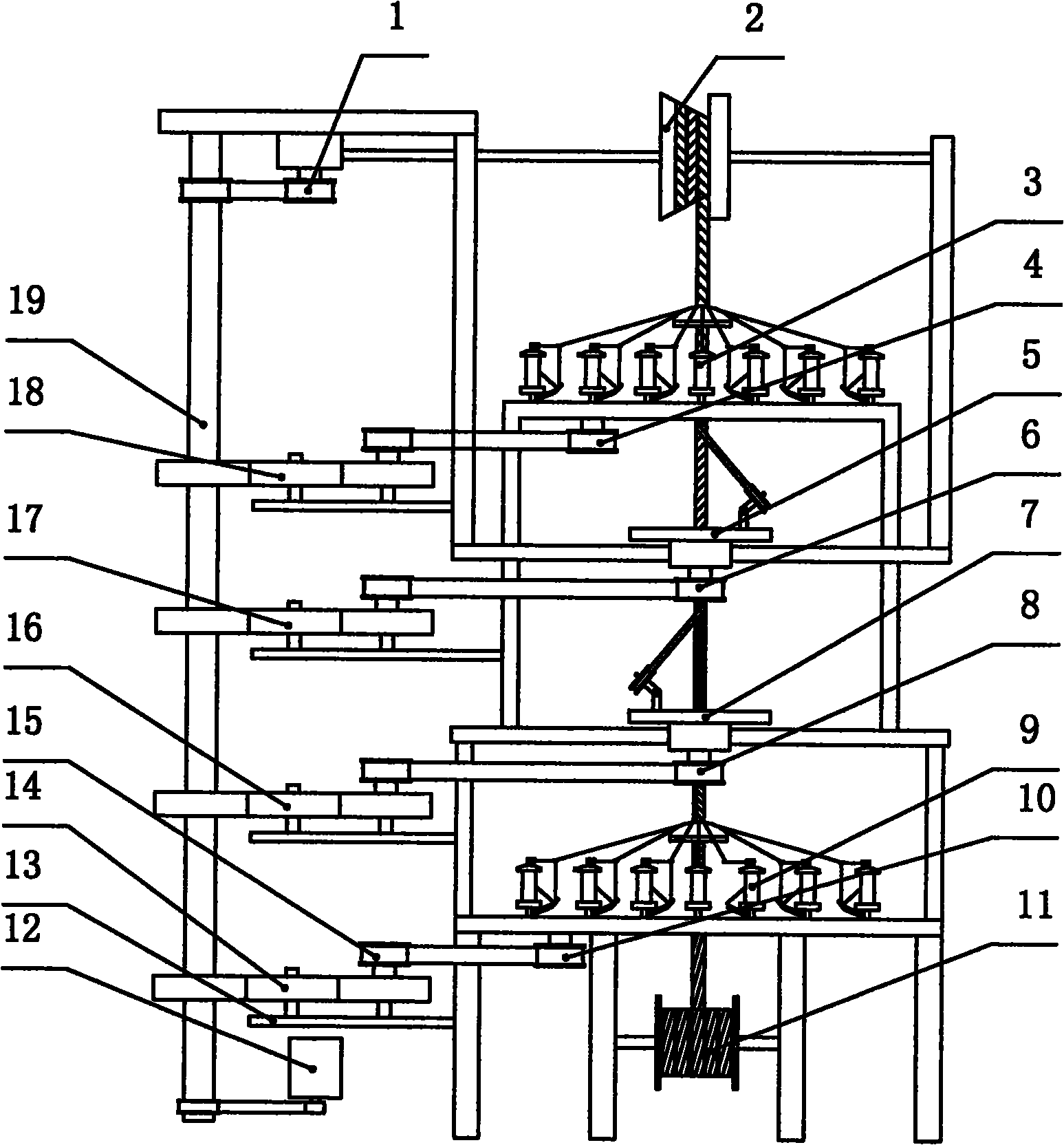

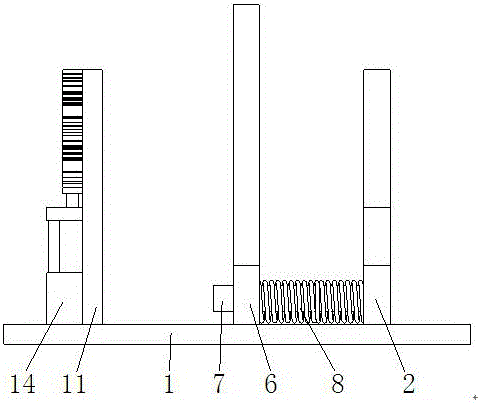

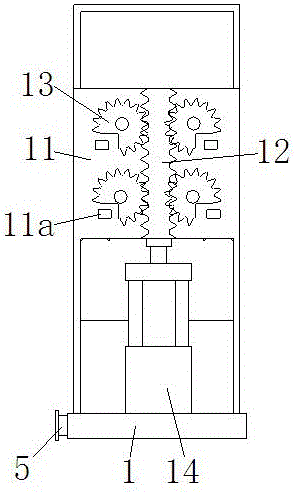

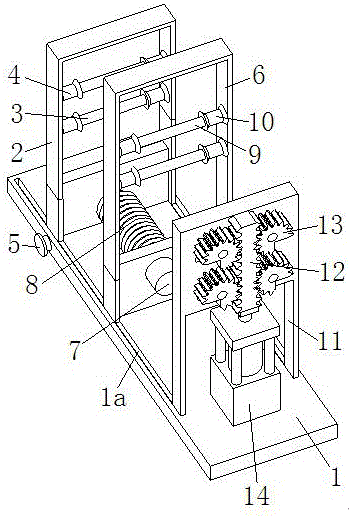

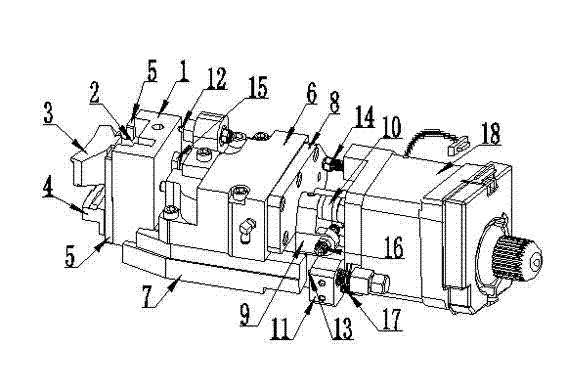

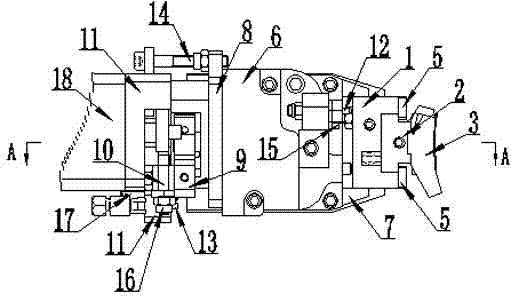

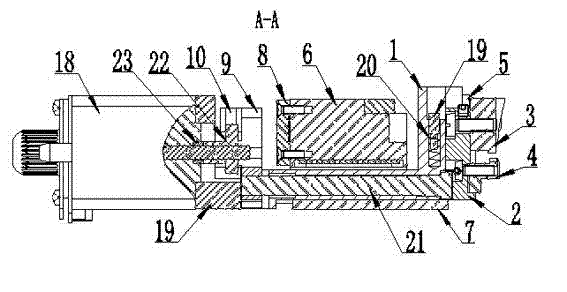

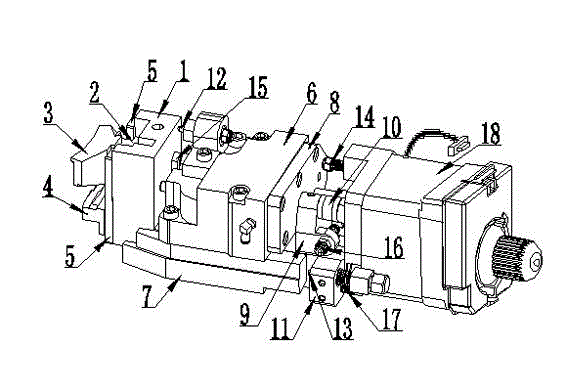

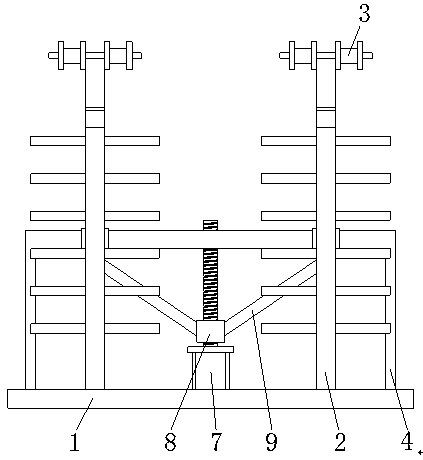

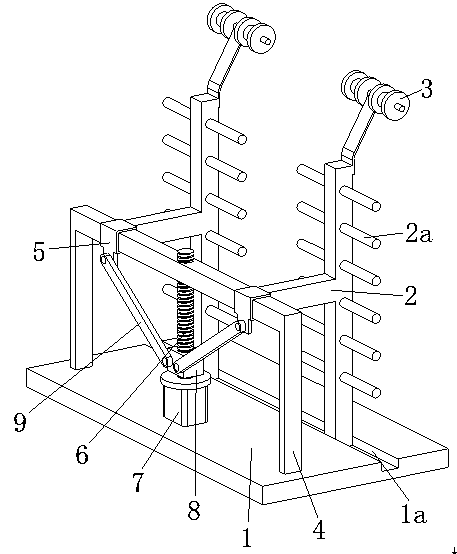

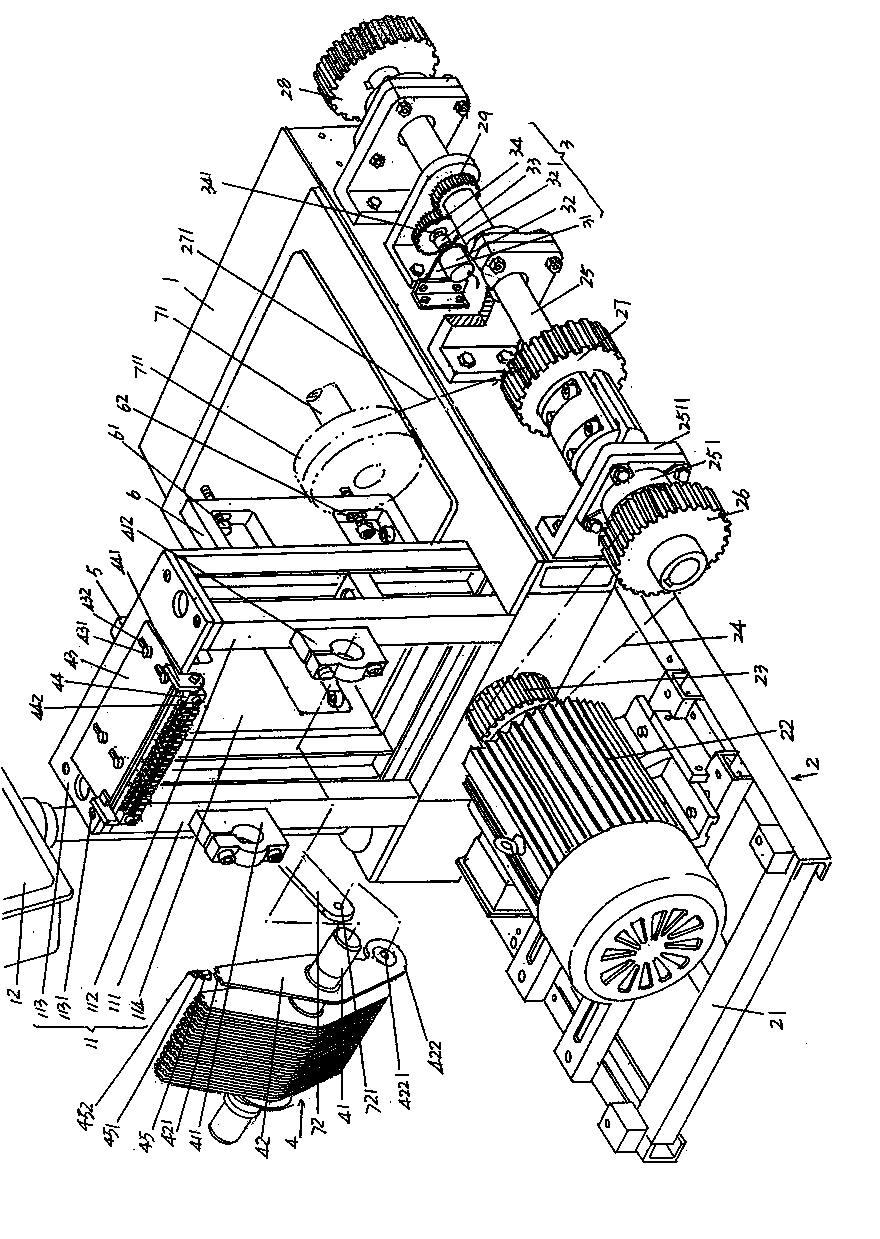

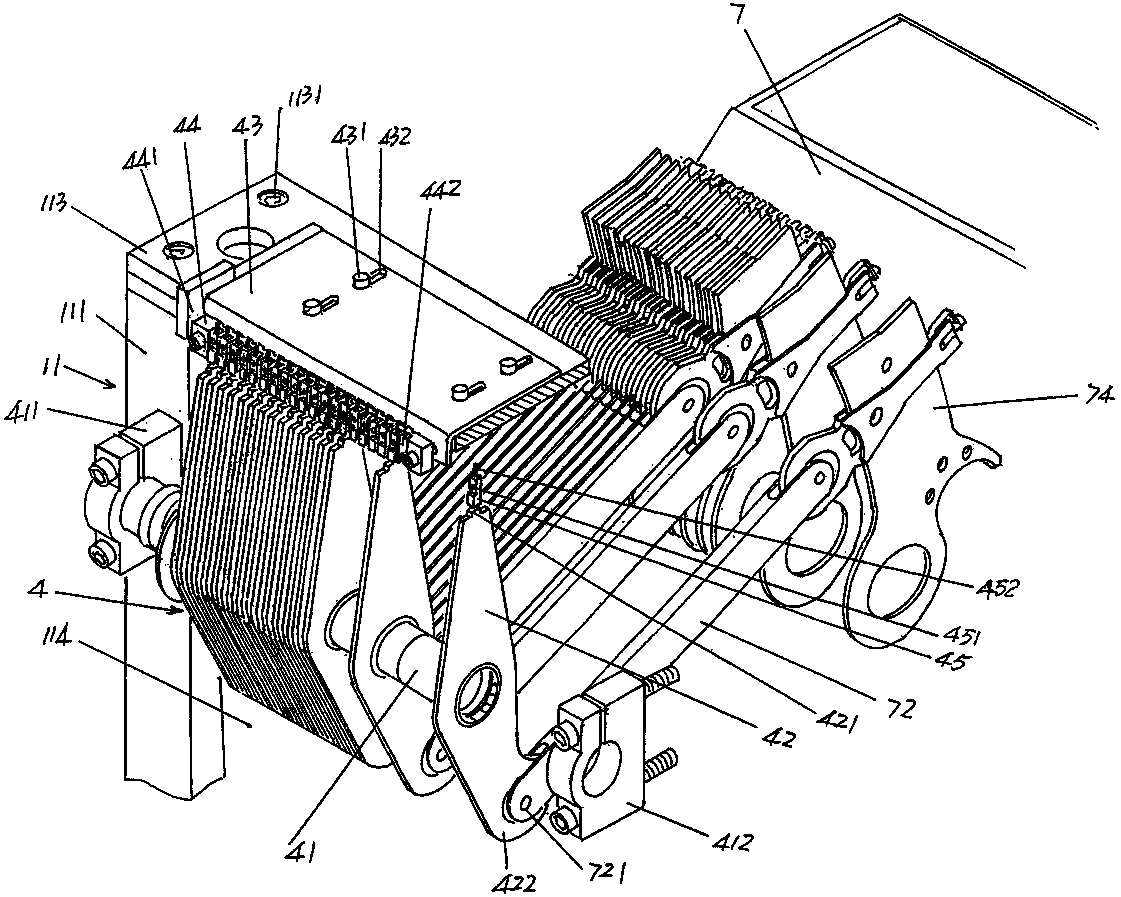

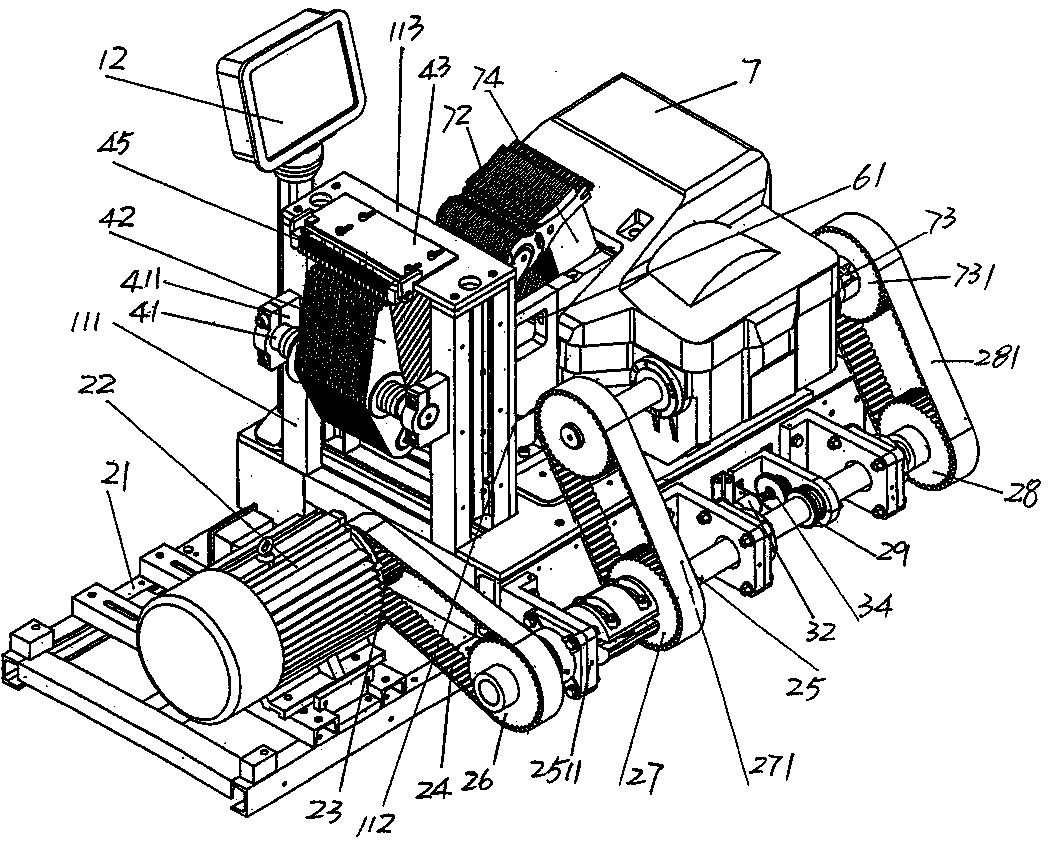

Double braiding and double wrapping integrated machine

InactiveCN102082014AReduce coat processing timeShorten the production cycleCable/conductor manufactureDrive motorEngineering

The invention relates to a double braiding and double wrapping integrated machine comprising a first braiding mechanism arranged on a stand, an unreeling mechanism, a traction mechanism, a traction driving mechanism, a first wrapping mechanism, a second wrapping mechanism and a second braiding mechanism, wherein the unreeling mechanism is arranged at the lower part of the first braiding mechanism, the traction mechanism is arranged above the first braiding mechanism, the first wrapping mechanism, the second wrapping mechanism and the second braiding mechanism are sequentially arranged between the first braiding mechanism and the traction mechanism from the bottom up, the respective driving mechanisms of the first braiding mechanism, the first wrapping mechanism, the second wrapping mechanism and the second braiding mechanism are respectively driven by a main shaft of the traction driving mechanism through a transmission mechanism, and the main shaft is driven by a driving motor. The double braiding and double wrapping integrated machine is scientific and reasonable in structural design, has a vertical multilayer braiding and wrapping structure, and can be used for continuously and efficiently completing the jacket processing procedure for closed type motor lead wires.

Owner:TIANJIN HUAZHIYANG SPECIAL CABLE

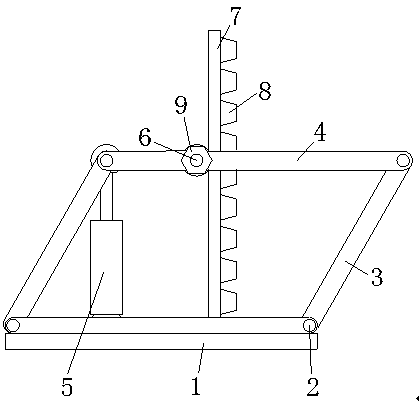

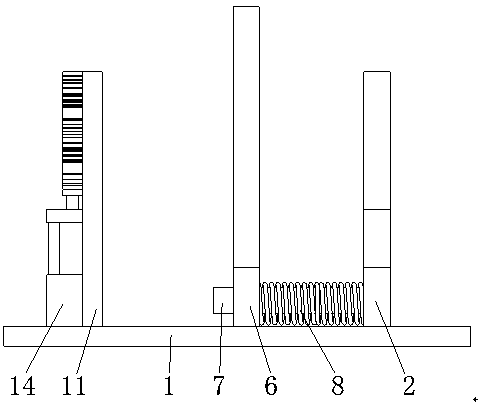

Loading device for flat filament

The invention discloses a loading device for a flat filament. The loading device comprises a support plate, wherein a chute is formed in the upper end of the support plate, a slide frame I is mounted on the right part of the chute, connecting shafts I are uniformly mounted at the upper part of the slide frame I, and guide wheels I are uniformly mounted on the outer walls of the connecting shafts I; a slide frame II is mounted in the middle of the chute, connecting shafts II are uniformly mounted at the upper part of the slide frame II, and guide wheels II are uniformly mounted on the outer walls of the connecting shafts II; and a connecting plate is mounted on the left part of the support plate, a rack is mounted in the middle of the connecting plate, limiting blocks are mounted on the front end of the connecting plate, and an air cylinder is mounted at the upper end of the support plate. The loading device has the advantages of reasonable structural design, convenience in maintenance and the like; by guiding through the guide wheels I and the guide wheels II, the tension degree of the flat filament is controlled, and the weaving quality of the flat filament is guaranteed; and by utilizing the rotatable limiting blocks, the flat filament is clamped and fixed, the manual loading is facilitated, and a lot of manpower and material resources are saved.

Owner:WUHU HANGDA NETWORK IND CO LTD

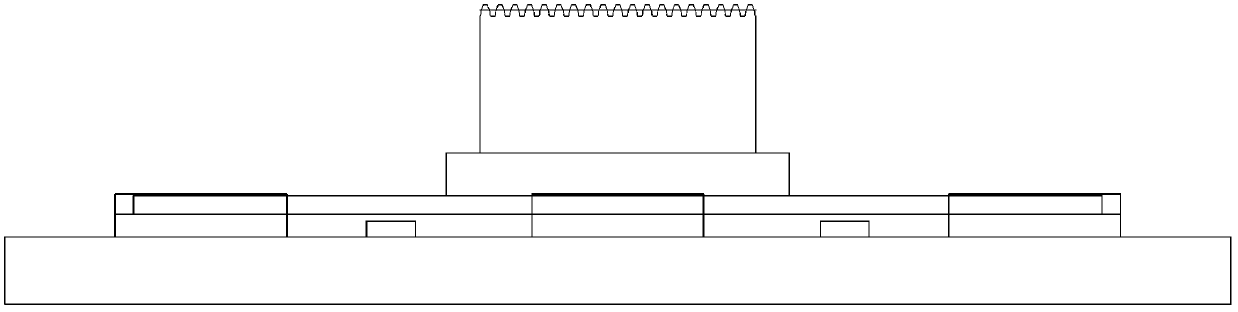

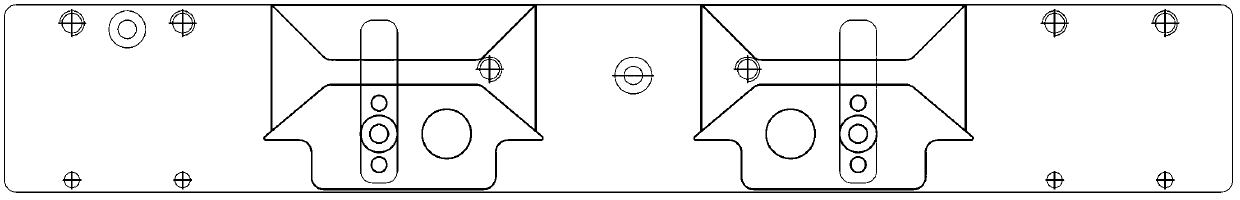

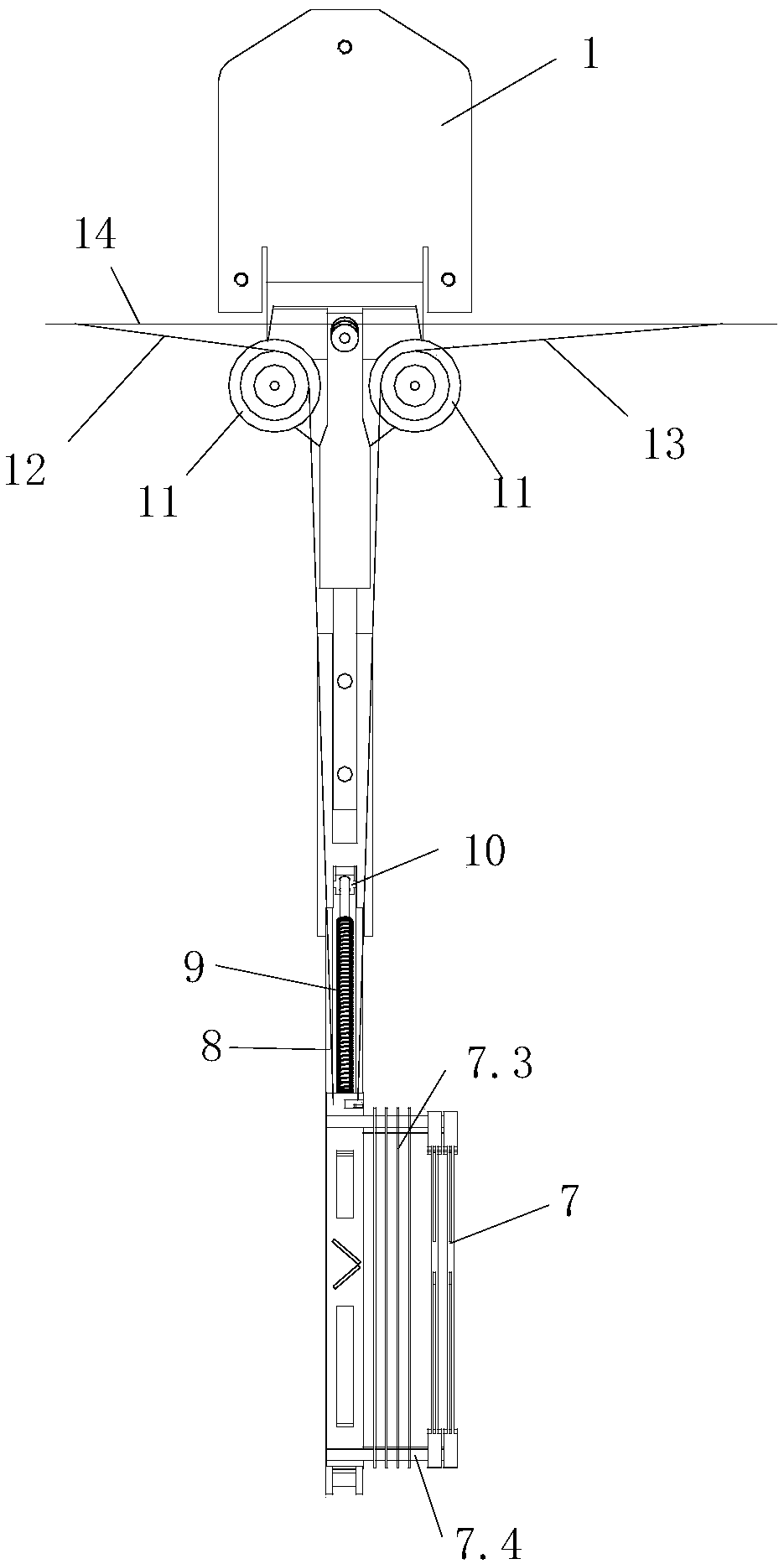

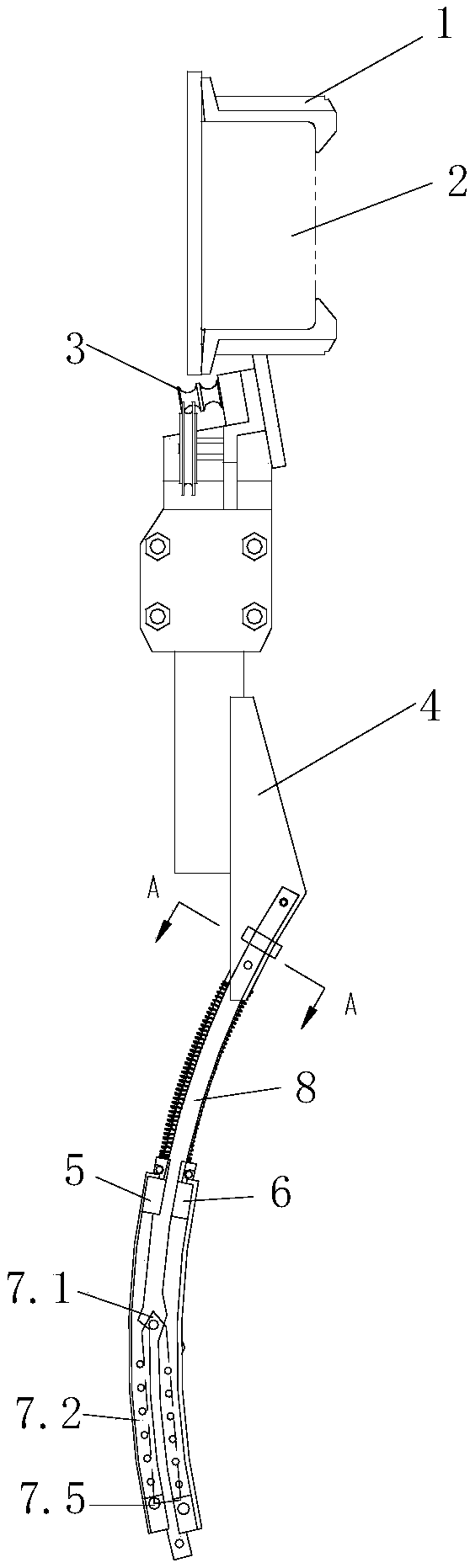

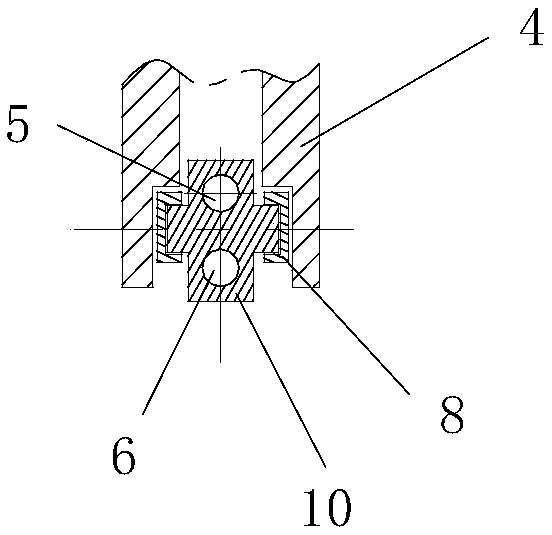

Sinking type fabric draw-off mechanism of full-forming intelligent flat knitting machine

The invention relates to a sinking type fabric draw-off mechanism of a full-forming intelligent flat knitting machine. The draw-off mechanism has the advantages of being good in draw-off effect, high in working efficiency and simple in structure. The full-forming intelligent flat knitting machine is made to not only have the normal functions of a computerized flat knitting machine, but also have a new function of carrying out cylinder knitting forming. According to the technical scheme, the sinking type fabric draw-off mechanism of the full-forming intelligent flat knitting machine comprises sinking mechanisms mounted on two side knitting mechanisms respectively and a pair of cloth rolling rollers located below a needle bed, and each sinking mechanism comprises a set sinkers and sinker triangles matched with the sheet removing clocks of the sinkers. The sinking type fabric draw-off mechanism of the full-forming intelligent flat knitting machine is characterized in that the sinkers are hinged to a small faller, the distance between the sheet removing clocks of the sinkers and the hinged points is equal to 50% to 60% of the distance between a pressing portion and the hinged points, and the included angles between the connection lines between the pressing portions of the sinkers and the hinged points and the horizontal plane crossing the hinged points are + / -25 degrees.

Owner:浙江万事兴机械有限公司

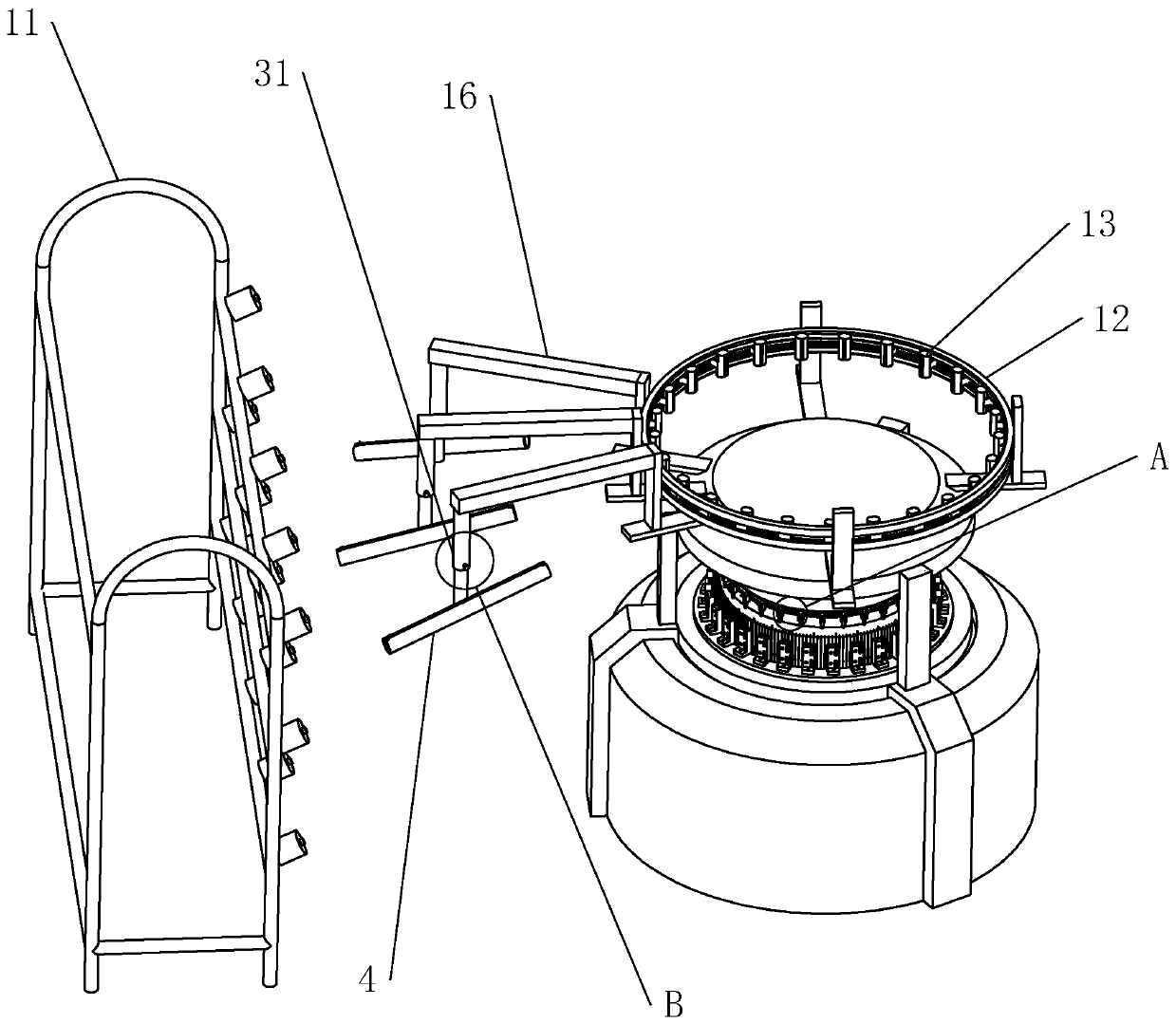

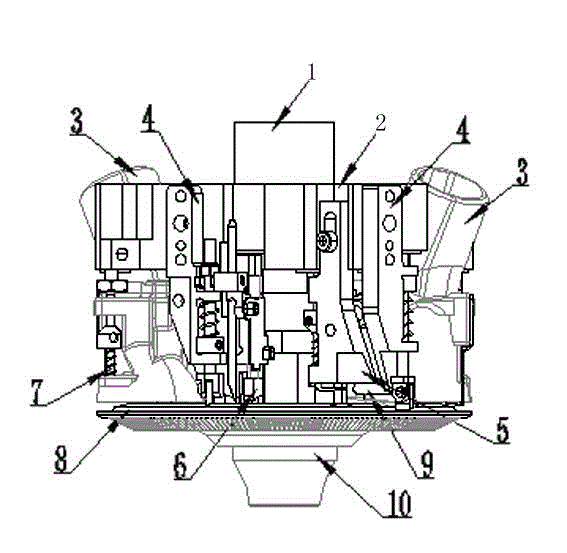

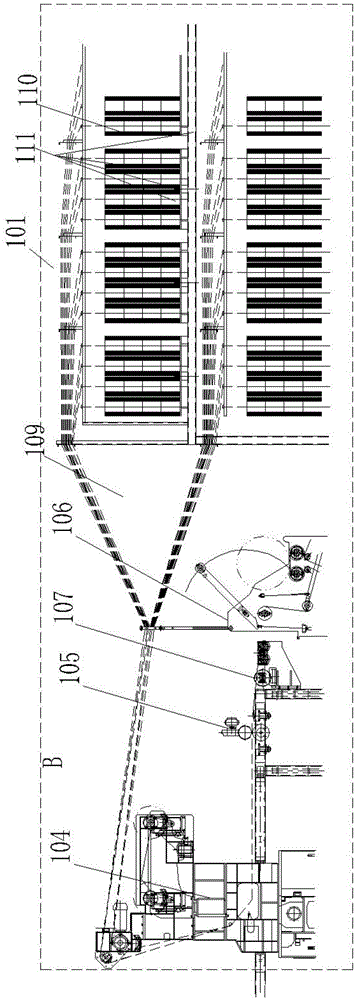

Novel plastic circular weaving machine

InactiveCN105734788AGuaranteed weaving qualityImprove work efficiencyCircular loomsWoven fabricTransmission system

An objective of the invention is to provide a plastic circular weaving machine whose shuttles do not roll organzine, weaving machine operating speed is adjustable, knitting quality is high, and woven products are large in diameter. The circular weaving machine comprises a main machine, let-off motions, a cloth lifting device, and a cloth winding-up device. The main machine is arranged on the upper part of a platform body, and the platform body is in a hexagon structure. The internal of the main machine includes a transmission system, and the transmission system is internally provided with a speed adjusting device. Ten shuttles are installed in the main machine. The main machine is connected with six let-off motions. The plastic circular weaving machine can adjust the rotating speed of the main machine aimed at different weaving materials, so as to ensure material weaving quality and improve working efficiency. The shuttles of the circular weaving machine do not roll organzine, and would not generate oil stain, and is not prone to fluff and break. The circular weaving machine can weave fabrics in larger diameters, and energy consumption is substantially reduced.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

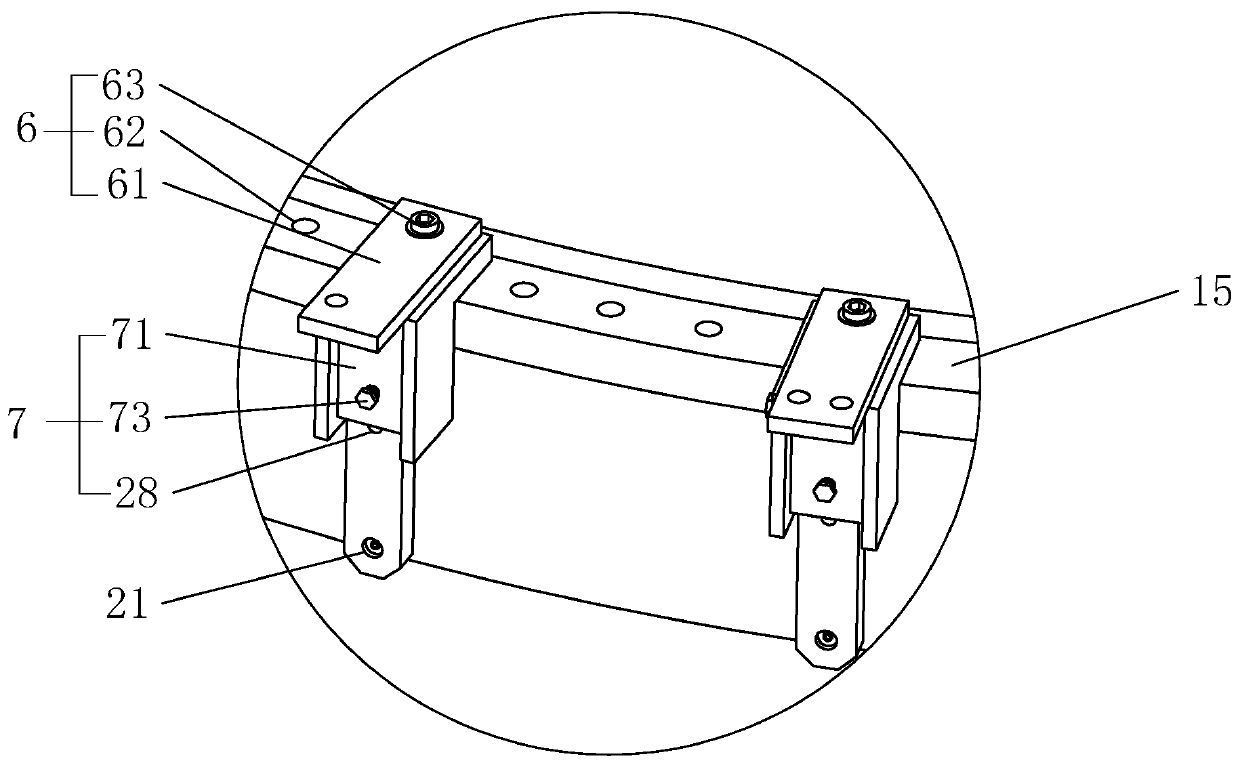

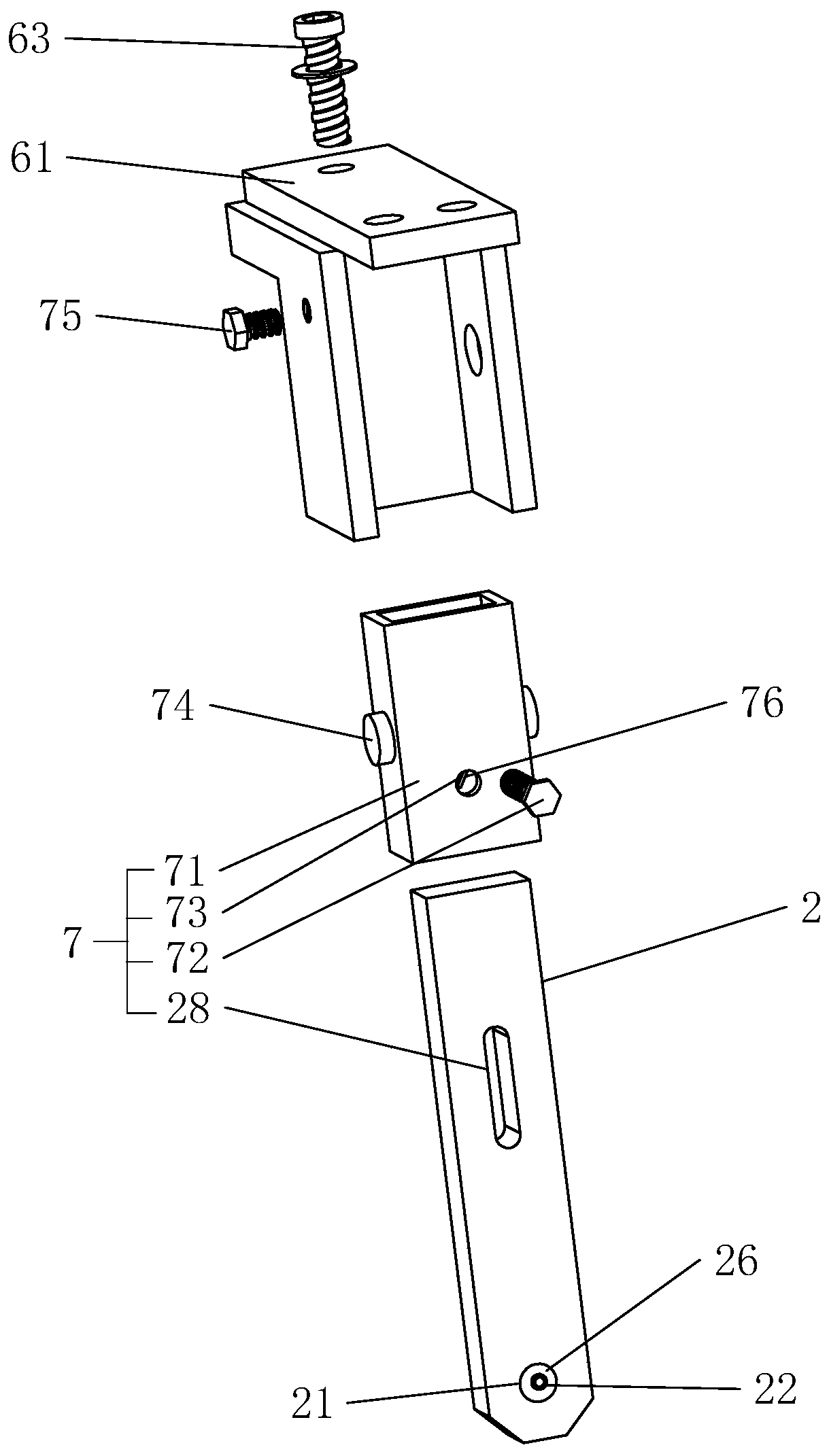

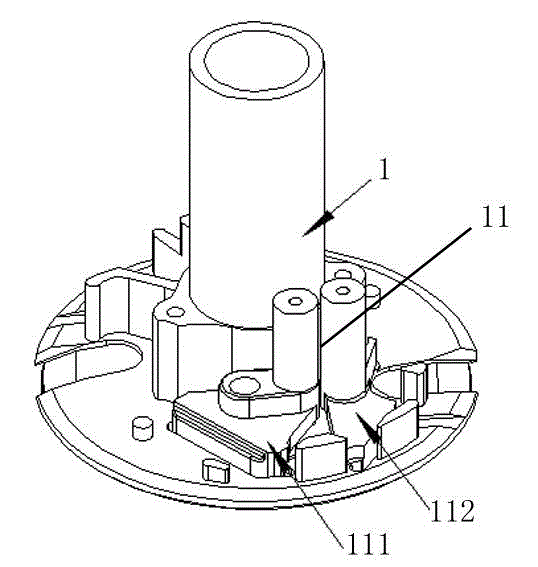

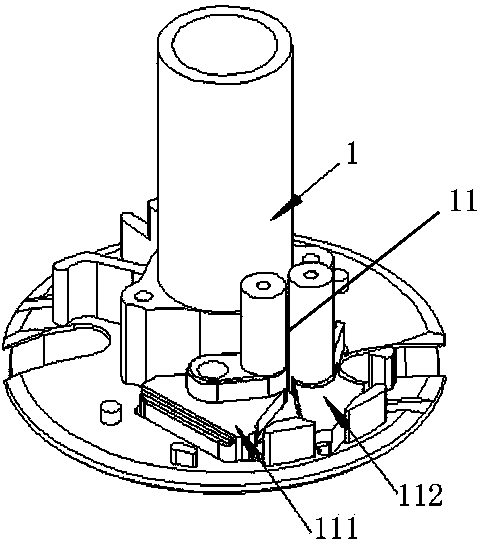

A Yarn Feeding Mechanism of Large Circular Knitting Machine

The invention relates to the technical field of circular knitting machines, and discloses a yarn feeding mechanism of a circular knitting machine. The yarn feeding mechanism of the circular knitting machine includes a creel, a support ring, a yarn storage device and a yarn feeding opening, wherein the creel is placed on the ground around the circular knitting machine, the support ring is arrangedon a rack of the circular knitting machine, the yarn storage device is arranged on the support ring, and the yarn feeding opening is formed in a dial of the circular knitting machine; a height liftingassembly is arranged between the creel and the yarn feeding mechanism and includes a height retractable part and a lifting pulley, the lifting pulley is arranged on the height retractable part, the lifting pulley is located at the height between the creel and the yarn storage device, and yarn on a yarn ring of the creel is unwound and then bypasses the lifting pulley to be imported into the yarnstorage device. According to the yarn feeding mechanism of the circular knitting machine, the lifting pulley is adopted to lift the yarn between the creel and the yarn storage device, the yarn is prevented from being touched when workshop workers walk, tidiness of the yarn is improved, and the yarn is prevented from breaking.

Owner:绍兴美科针纺有限公司

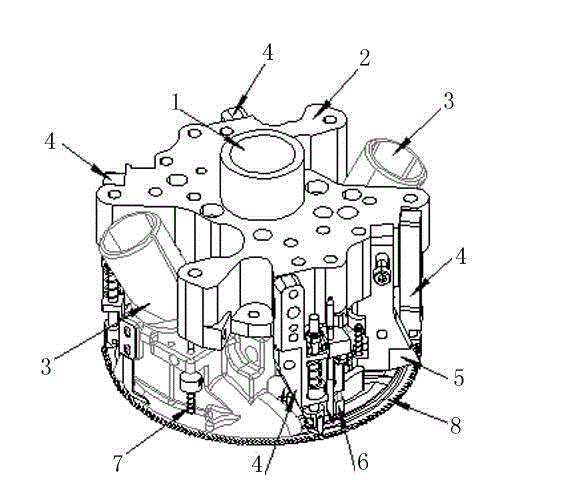

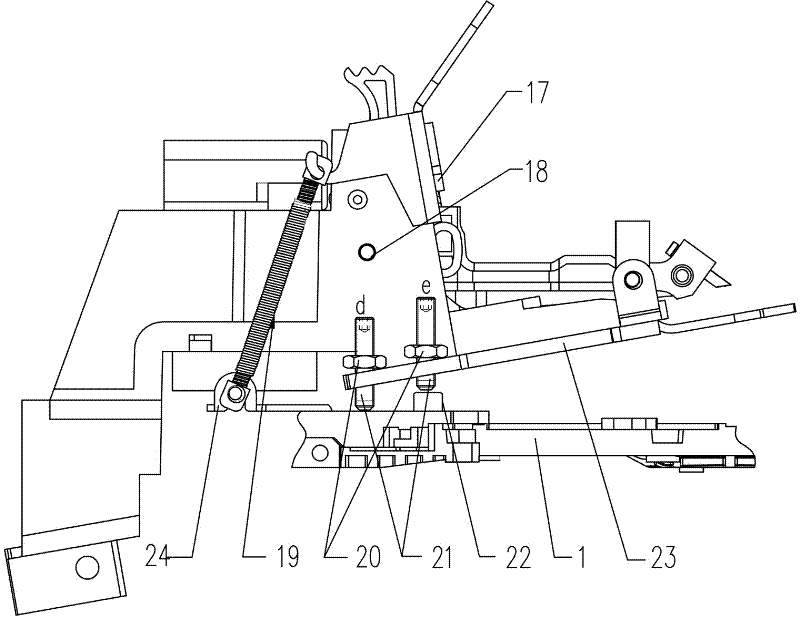

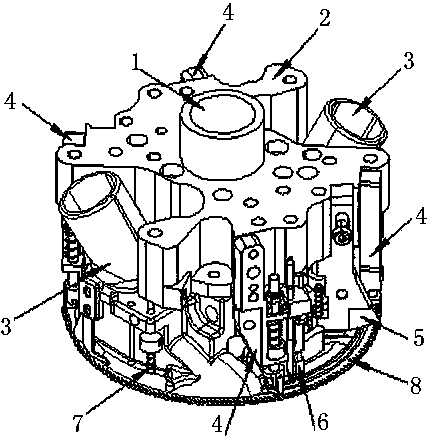

Tying device for hosiery circular knitting machine

The invention discloses a tying mechanism for a hosiery circular knitting machine. The tying mechanism comprises an air valve seat, a suction port, an upper scissors mechanism, a thread guard mechanism, a thread pressing mechanism, a suction port thread guard mechanism and a thread clamping mechanism, wherein the above mechanisms are all mounted on a huff disc seat; disc scissors are arranged below the huff disc seat; and a huff disc is arranged below the disc scissors. the upper scissors mechanism mainly cooperate with the disc scissors for combined action; with the center point of the disc scissors as the circle point, under program control, the disc scissors rotate, and the upper scissors mechanism is fixed on the air valve seat and does not move; through mobile and static combination, a shearing force is generated to shear floating threads and redundant threads generated in the knitting process. By adopting the tying mechanism, the waste yarns and redundant threads shearing efficiency can be effectively improved, the machine fault rate is reduced, the maintenance cost is directly saved for users, and the production efficiency is greatly improved. The tying mechanism is simple in structure, and tidy and beautiful in appearance, can effectively improve the knitting efficiency of textiles, and ensures the appearance quality of the textiles.

Owner:NINGBO CIXING

Yarn feeding device of computer silk stockings machine

ActiveCN101994207BReach the function of limit adjustmentPrevent closing and decouplingWeft knittingYarnEngineering

The invention discloses a yarn feeding device of a computer silk stockings machine, which comprises a shuttle cylinder body and multiple yarn feeding shuttles, wherein the shuttle cylinder body is provided with multiple first cylinder pistons and push rods with springs; the multiple yarn feeding shuttles are axially connected to the shuttle cylinder body through cylindrical hinge pins; the tail part of each yarn feeding shuttle respectively corresponds to one first cylinder piston and one push rod with the spring, and the cylinder pistons and the push rods with the springs are matched; the shuttle cylinder body is also provided with multiple second cylinder pistons; and the tail part of each yarn feeding shuttle respectively corresponds to one second cylinder piston and is matched with the corresponding second cylinder piston. Compared with the existing technique, the yarn feeding device enhances the use performance of the computer silk stockings machine and the stability in the knitting course, solves the problems of incorrect yarn feeding and low relevant speed in the existing technique, guarantees the knitting quality of the product, enhances the working efficiency and can satisfy the marketization requirements by adopting the technical scheme.

Owner:NINGBO CIXING

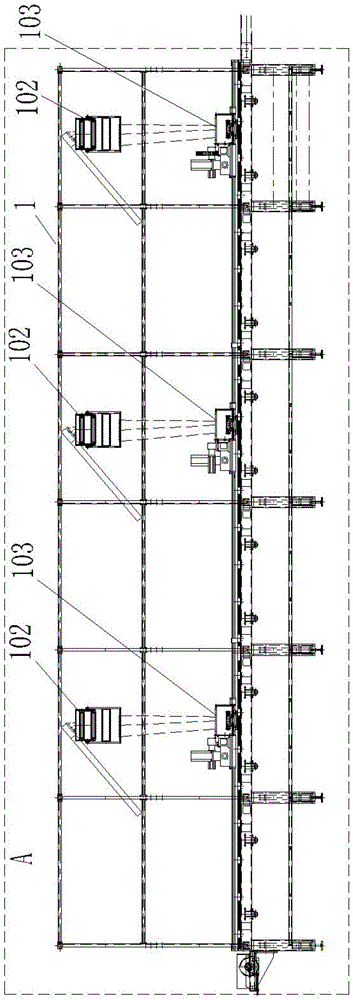

Multiaxial warp knitting machine

ActiveCN104947306AReduce wearPlay a protective effectFlat warp knitting machinesEngineeringWeft yarn

The invention relates to a multiaxial warp knitting machine. The multiaxial warp knitting machine comprises a machine frame, a warp yarn unwinding mechanism, a weft yarn unwinding mechanism, a weft yarn laying device, a knitting mechanism for knitting yarns, a cutting device and a winding mechanism. The weft yarn unwinding mechanism comprises a yarn arranging mechanism arranged on the machine frame. The yarn arranging mechanism comprises a yarn guide frame arranged on the machine frame. A swinging frame for performing reciprocating swinging relative to the yarn guide frame is arranged on the yarn guide frame. At least two yarn guide rollers arranged in a spaced mode are arranged in the yarn guide frame. Yarn guide rods with the number corresponding to the number of the yarn guide rollers and yarn penetrating plates assembled on the swinging frame and provided with yarn penetrating holes are arranged in the swinging frame. By means of the multiaxial warp knitting machine, the problem that in the prior art, as the width of yarn guide rollers needs to be increased, the tension of laid weft yarns is not coincident can be solved, it is finally guaranteed that the knitting process is smoothly carried out, the knitting efficiency is improved, and the product knitting quality can also be guaranteed.

Owner:NEWTRY COMPOSITE

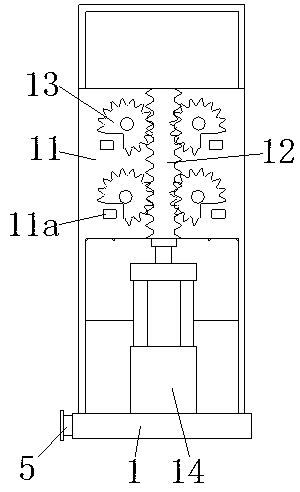

Circular knitting machine density regulating device with inductive alarm mechanism

The invention discloses a circular knitting machine density regulating device with an inductive alarm mechanism, which comprises a driving mechanism, a transmission mechanism, a dynamic density triangular mechanism and a piston mechanism, wherein the driving mechanism, the transmission mechanism, the dynamic density triangular mechanism and the piston mechanism are all mounted on a triangular base; the driving mechanism drives the dynamic density triangular mechanism to move through the transmission mechanism; a fixing frame is arranged at the upper part of a dynamic density cylinder body; the alarm mechanism is mounted on the fixing frame; the inductive alarm mechanism comprises an insert, an elastic component, a sensor hexagon nut and a sensor pin; the sensor pin is sleeved with the sensor hexagon nut; the middle upper part of the sensor pin is sleeved with the elastic component; and the bottom end face of the sensor pin can be in contact with a sensing plane on the dynamic density triangular base. If the semi-position is not realized, the sensor pin is in contact with the sensing plane on the dynamic density triangular base, which is abnormal, and the sensor alarms. The device is simple in structure and sensitive to alarm.

Owner:NINGBO CIXING

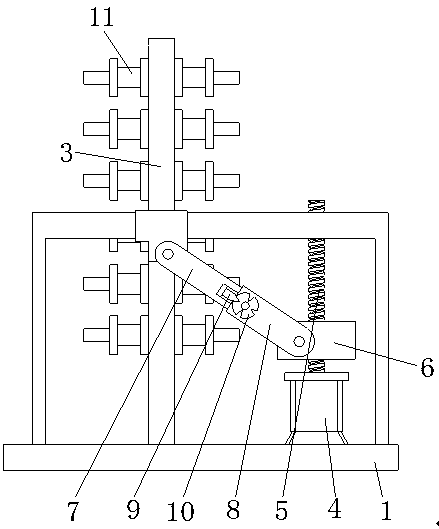

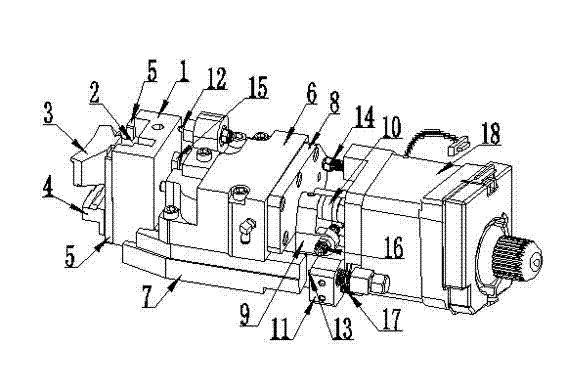

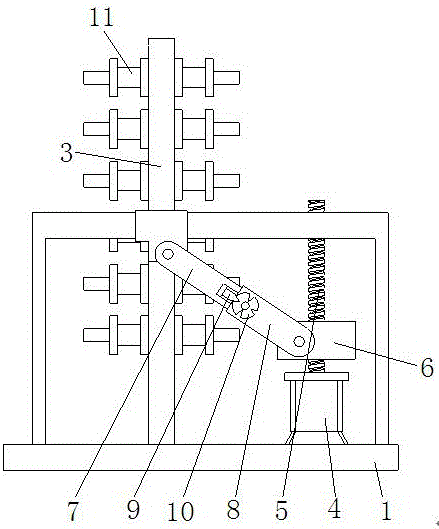

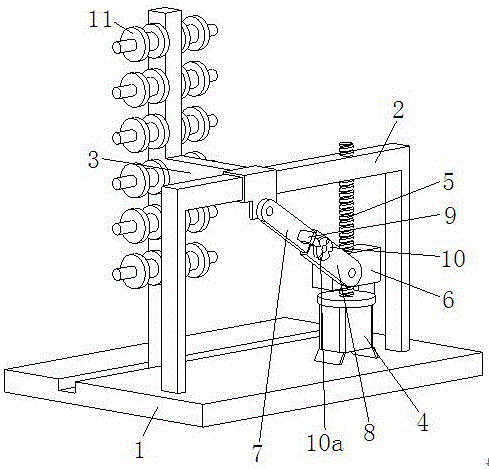

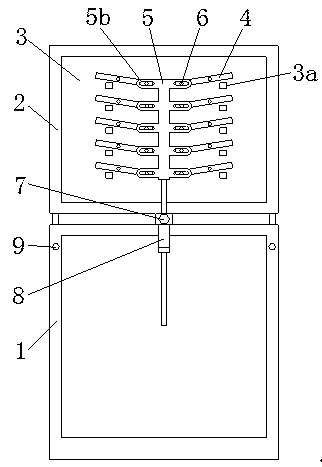

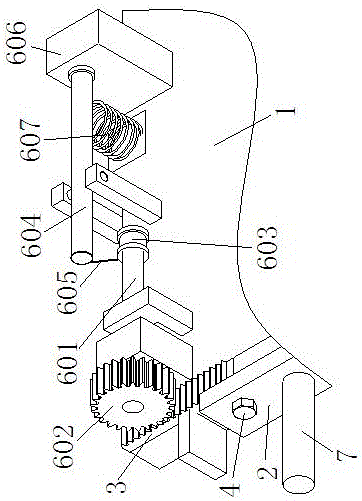

Circular knitting machine density adjusting device with density cam mechanism

InactiveCN102912549AImprove performanceGuaranteed weaving qualityWeft knittingElectric machineryEngineering

The invention discloses a circular knitting machine density adjusting device with a density cam mechanism, which comprises a driving mechanism, a transmission mechanism, a dynamic density triangular mechanism and a piston mechanism, wherein the driving mechanism, the transmission mechanism, the dynamic density triangular mechanism and the piston mechanism are all arranged on a triangular base, and the driving mechanism drives the dynamic density triangular mechanism to move through the transmission mechanism; the density cam mechanism is composed of a density cam and a transmission rod, and the density cam is fixedly connected to one end of the transmission rod; and the density cam is arranged in a groove of a dynamic density triangular sliding block. When a density motor works, the transmission rod transmits the rotation to the density cam, and the density cam can press down the dynamic density triangular sliding block through rotating in the groove of the dynamic density triangular sliding block. Through the density cam mechanism with the structure, sensitive action and stable performance can be achieved in the adjusting process, so that the weaving quality of the fabric is ensured, and the stability of a machine is improved.

Owner:NINGBO YUREN NUMERICAL CONTROL TECH

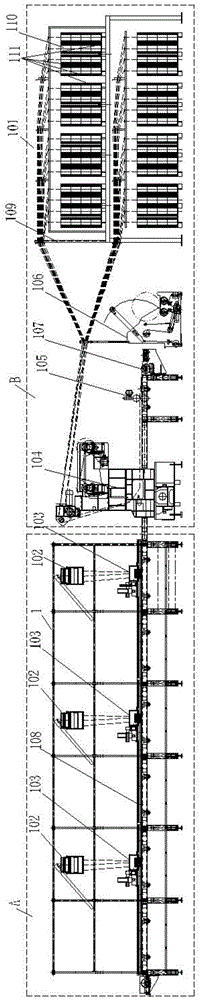

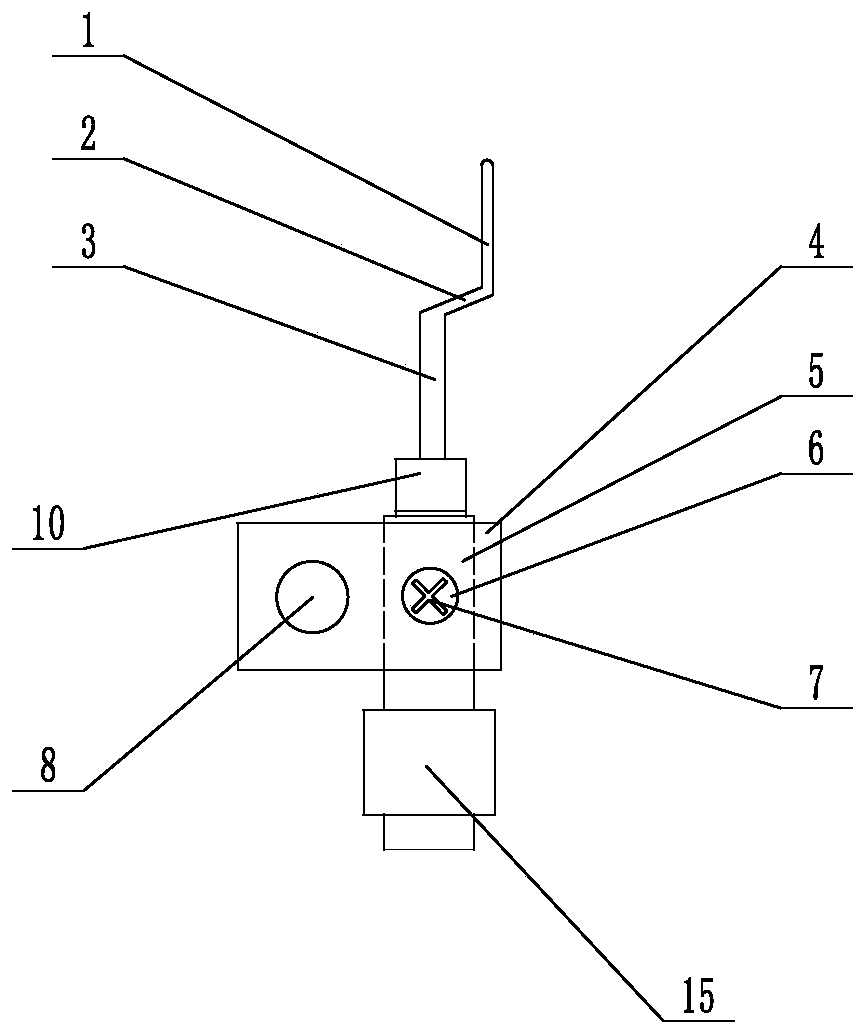

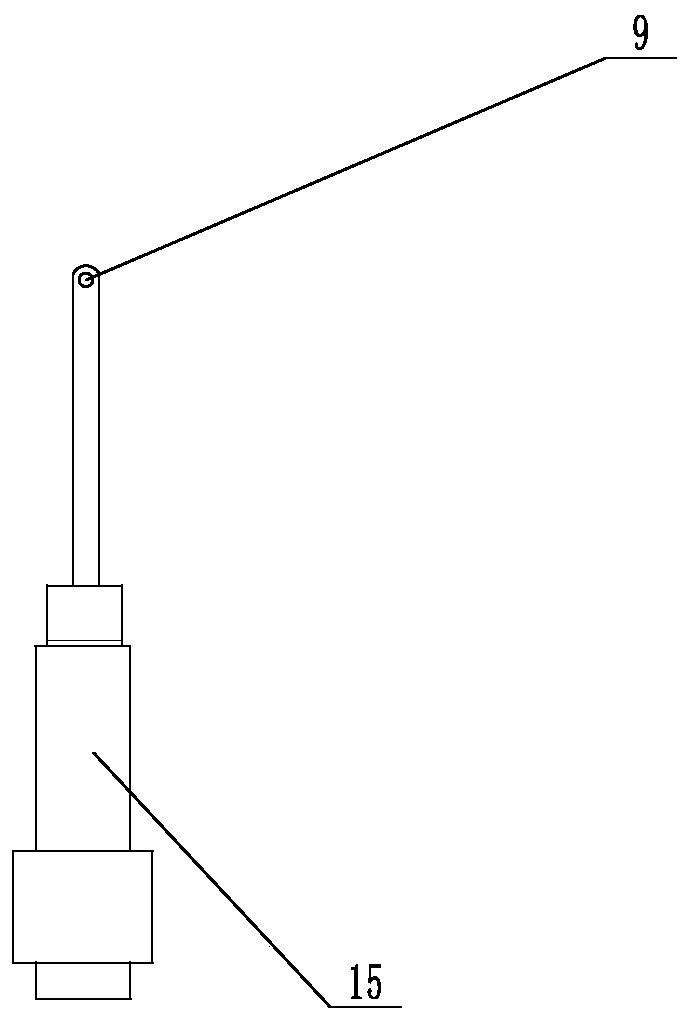

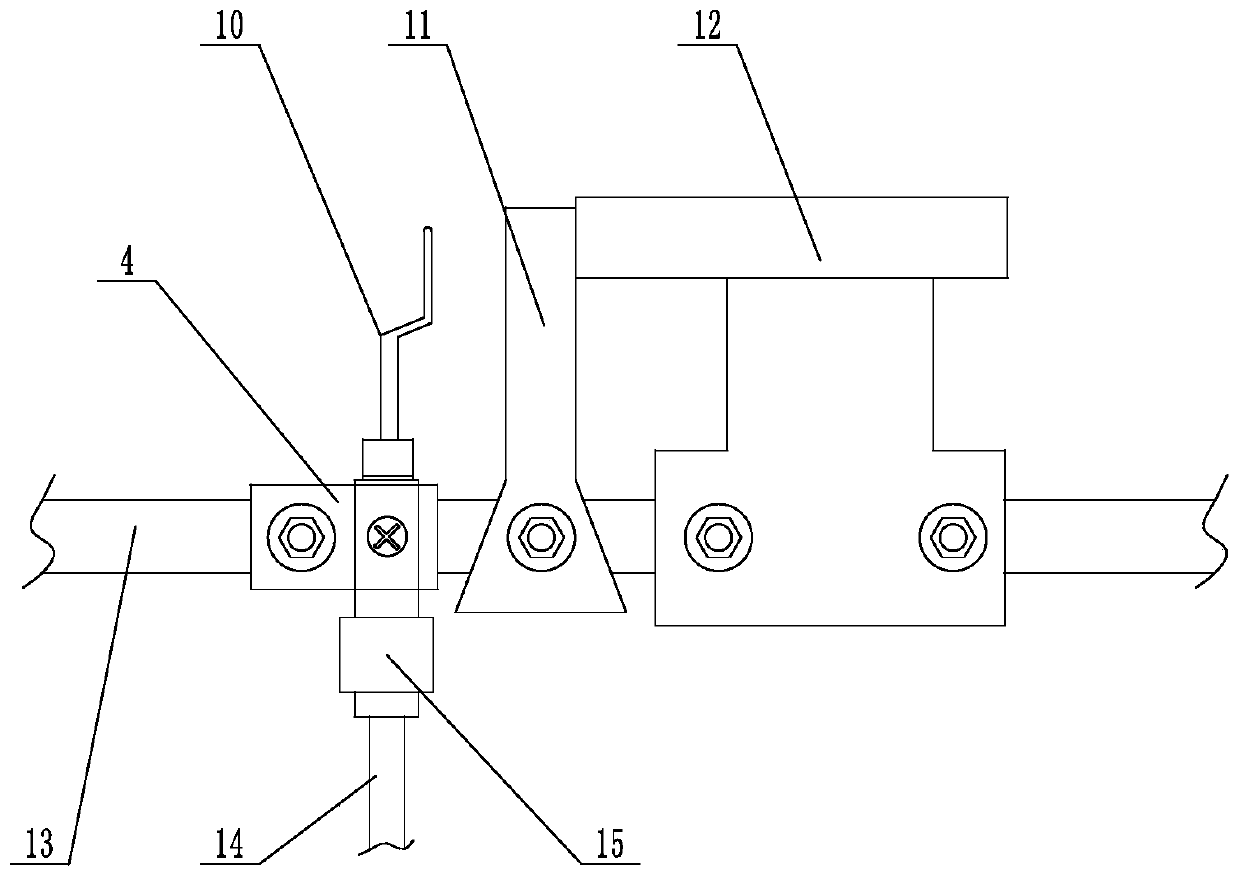

Stretching auxiliary spraying system for reducing length of waste selvage yarns of air-jet loom

InactiveCN110886043AGuaranteed normal interleavingGuaranteed weaving qualityLoomsAir-jet loomProcess engineering

The invention belongs to the technical field of textile equipment, and particularly relates to a stretching auxiliary spraying system for reducing the length of waste selvage yarns of an air-jet loom.The stretching auxiliary spraying system comprises a reed base, an auxiliary spraying device, a photoelectric weft detector and a stretching auxiliary spraying channel, the auxiliary spraying devicecomprises a spraying pipe and a base, a mounting hole is formed in the base, the spraying pipe penetrates the mounting hole and is fixed onto the base, a circular pipe, a transition pipe and a flat pipe are sequentially connected from bottom to top to form the spraying pipe, the flat pipe is perpendicular to the reed base, a nozzle is horizontally arranged at the top of the flat pipe, the distancebetween the nozzle and the central axis of the mounting hole is 4-8mm, and an airflow outlet of the nozzle faces the photoelectric weft detector and the stretching auxiliary spraying channel. By improving the structure of the auxiliary spraying device, sufficient straightening of weft yarns and good interweaving of the waste selvage yarns can be ensured, the length of the waste selvage yarns is reduced, cost is saved, the stretching auxiliary spraying system has considerable economic benefits, weaving weft shrinkage is reduced, and quality is improved.

Owner:鲁丰织染有限公司

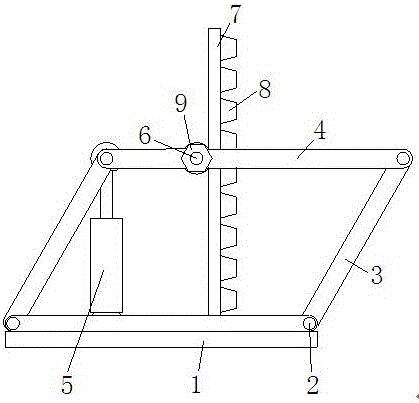

Feeding device for ore filter screen silk threads

The invention discloses a feeding device for ore filter screen silk threads. The device comprises a lower plate, the upper end of the lower plate is equipped with a sliding chute, the left part and right part of the sliding chute are both equipped with a sliding rack, the upper ends of the sliding racks are evenly equipped with guide wheels, the rear part of the lower plate is equipped with a support rack, sliding blocks are mounted at the left part and right part of the support rack, a threaded rod is mounted at the middle part of the support rack, a motor is installed on the lower plate, a driving block is mounted on the outer wall of the threaded rod, and the left part and right part of the driving block are both equipped with a connecting rod. The feeding device provided by the invention has the advantages of reasonable structural design, and convenient use, etc., realizes feeding of silk threads to an ore filter screen through cooperation of the threaded rod and the driving block, replaces common roller feeding, guarantees the knitting quality of the ore filter screen, and saves a lot of manpower and materails resources.

Owner:WUHU HANGDA NETWORK IND CO LTD

An adjustable feeding device for sewage filter

The invention discloses an adjustable feeding device for a sewage filtering screen. The adjustable feeding device comprises a lower bottom plate. A supporting frame is mounted on the front portion of the lower bottom plate. A sliding frame is mounted on the left portion of the supporting frame. A motor is mounted on the right portion of the lower bottom plate. A screw is mounted on the right portion of the supporting frame. A driving block is mounted on the outer wall of the screw. A first linkage rod is mounted at the front end of the sliding frame. A second linkage rod is arranged on the outer wall of the first linkage rod in a sleeving mode. The first linkage rod is provided with a clamping-connection block. The second linkage rod is provided with a positioning block. The adjustable feeding device has the advantages of being reasonable in structural design, convenient to use and the like, through the movable sliding frame, moving of raw materials is achieved, and the weaving quality of the sewage filtering screen is ensured; and through matching of the clamping-connection block and the positioning block, the distance between the first linkage rod and the second linkage rod is adjusted, the using range of the adjustable feeding device is enlarged, and lots of manpower and material resources are saved.

Owner:WUHU HANGDA NETWORK IND CO LTD

Circular knitting machine density regulating device with inductive alarm mechanism

ActiveCN102926122BAvoid wear and tearGuaranteed weaving qualityWeft knittingElastic componentFixed frame

The invention discloses a circular knitting machine density regulating device with an inductive alarm mechanism, which comprises a driving mechanism, a transmission mechanism, a dynamic density triangular mechanism and a piston mechanism, wherein the driving mechanism, the transmission mechanism, the dynamic density triangular mechanism and the piston mechanism are all mounted on a triangular base; the driving mechanism drives the dynamic density triangular mechanism to move through the transmission mechanism; a fixing frame is arranged at the upper part of a dynamic density cylinder body; the alarm mechanism is mounted on the fixing frame; the inductive alarm mechanism comprises an insert, an elastic component, a sensor hexagon nut and a sensor pin; the sensor pin is sleeved with the sensor hexagon nut; the middle upper part of the sensor pin is sleeved with the elastic component; and the bottom end face of the sensor pin can be in contact with a sensing plane on the dynamic density triangular base. If the semi-position is not realized, the sensor pin is in contact with the sensing plane on the dynamic density triangular base, which is abnormal, and the sensor alarms. The device is simple in structure and sensitive to alarm.

Owner:NINGBO CIXING

A feeding device for ore filter wire

The invention discloses a feeding device for ore filter screen silk threads. The device comprises a lower plate, the upper end of the lower plate is equipped with a sliding chute, the left part and right part of the sliding chute are both equipped with a sliding rack, the upper ends of the sliding racks are evenly equipped with guide wheels, the rear part of the lower plate is equipped with a support rack, sliding blocks are mounted at the left part and right part of the support rack, a threaded rod is mounted at the middle part of the support rack, a motor is installed on the lower plate, a driving block is mounted on the outer wall of the threaded rod, and the left part and right part of the driving block are both equipped with a connecting rod. The feeding device provided by the invention has the advantages of reasonable structural design, and convenient use, etc., realizes feeding of silk threads to an ore filter screen through cooperation of the threaded rod and the driving block, replaces common roller feeding, guarantees the knitting quality of the ore filter screen, and saves a lot of manpower and materails resources.

Owner:WUHU HANGDA NETWORK IND CO LTD

Adjustable feeding device for sewage filtering screen

The invention discloses an adjustable feeding device for a sewage filtering screen. The adjustable feeding device comprises a lower bottom plate. A supporting frame is mounted on the front portion of the lower bottom plate. A sliding frame is mounted on the left portion of the supporting frame. A motor is mounted on the right portion of the lower bottom plate. A screw is mounted on the right portion of the supporting frame. A driving block is mounted on the outer wall of the screw. A first linkage rod is mounted at the front end of the sliding frame. A second linkage rod is arranged on the outer wall of the first linkage rod in a sleeving mode. The first linkage rod is provided with a clamping-connection block. The second linkage rod is provided with a positioning block. The adjustable feeding device has the advantages of being reasonable in structural design, convenient to use and the like, through the movable sliding frame, moving of raw materials is achieved, and the weaving quality of the sewage filtering screen is ensured; and through matching of the clamping-connection block and the positioning block, the distance between the first linkage rod and the second linkage rod is adjusted, the using range of the adjustable feeding device is enlarged, and lots of manpower and material resources are saved.

Owner:WUHU HANGDA NETWORK IND CO LTD

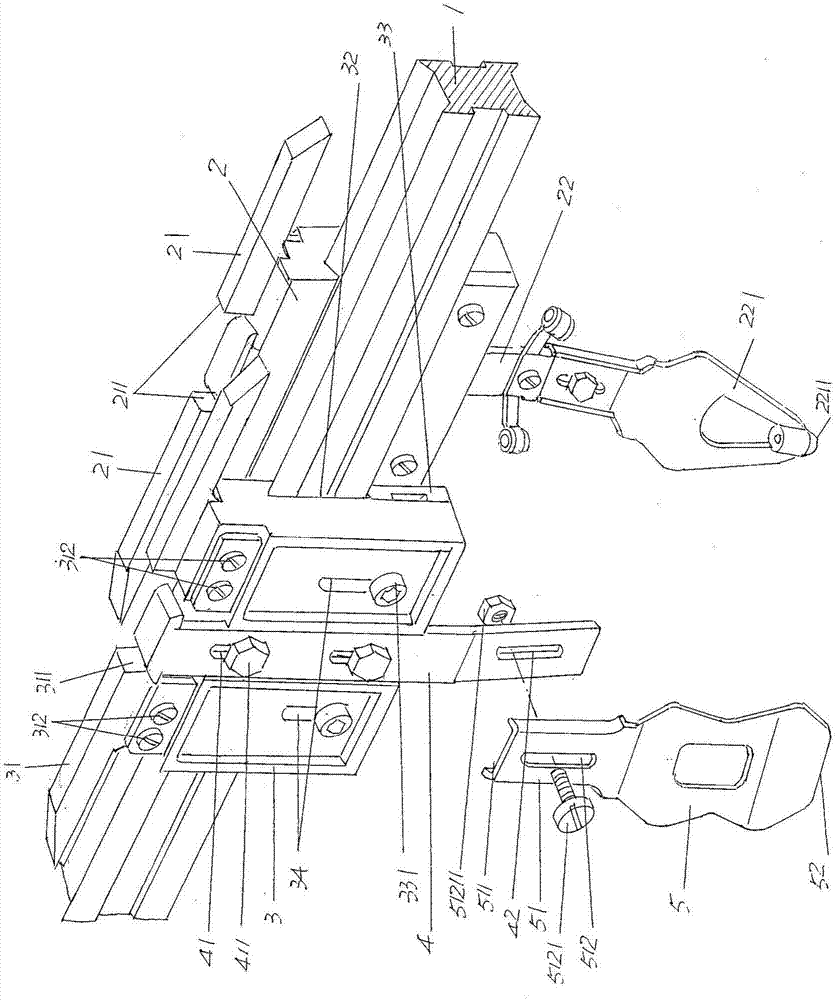

Edge twisting device for twisted edge or waste edge weaving

The invention discloses an edge twisting device for twisted edge or waste edge weaving. Edge twisting opening devices of the edge twisting device are mounted on a power pull rope of a power device, and that is to say, one power pull rope can drive two twisting opening devices to work synchronously at the same time; relative to the mode that power is transmitted through gears and racks in the priorart, the edge twisting opening devices cannot vibrate, and therefore the weaving quality of a weaving machine is ensured.

Owner:SHANDONG RIFA TEXTILE MACHINERY

Sinking type fabric draw-off mechanism of full-forming intelligent flat knitting machine

Owner:浙江万事兴机械有限公司

A wire gathering device for papermaking flat wire mesh

Owner:WUHU HANGDA NETWORK IND CO LTD

Pure silk broadcloth twist-free weaving technology

InactiveCN108823737AReduce areaGuaranteed weaving qualityWoven fabricsLiquid/gas/vapor yarns/filaments treatmentGramMass ratio

The invention discloses a pure silk broadcloth twist-free weaving technology, and belongs to the technical field of pure silk weaving. The technology is characterized in that a silk damping process isconducted for 43-47 minutes at the water temperature of 37-39 DEG C, the mass ratio of silk to water is 1:4.5-5.5, and after dehydration, the water content in the silk is 97%-103%; in a reeling process, the revolving speed of a main shaft is 472-477 revolutions per minute, the linear speed of the silk running is 127-133 meters per minute, and the tension applied to the silk is 8-10 grams; the warping process is that at least two pieces of silk are merged into one piece of silk by utilizing a lease line through a lease reed, and after warp pulling and reeling, weaving can be conducted. According to the technology, the technological process is shortened, compared with an original production technology, the technology conditions are adjusted, and after the four processes of doubling, twisting, silk steaming and setting and rewinding are omitted, the weaving quality of the pure silk can still be ensured.

Owner:ZIBO DARANFANG SILK GRP

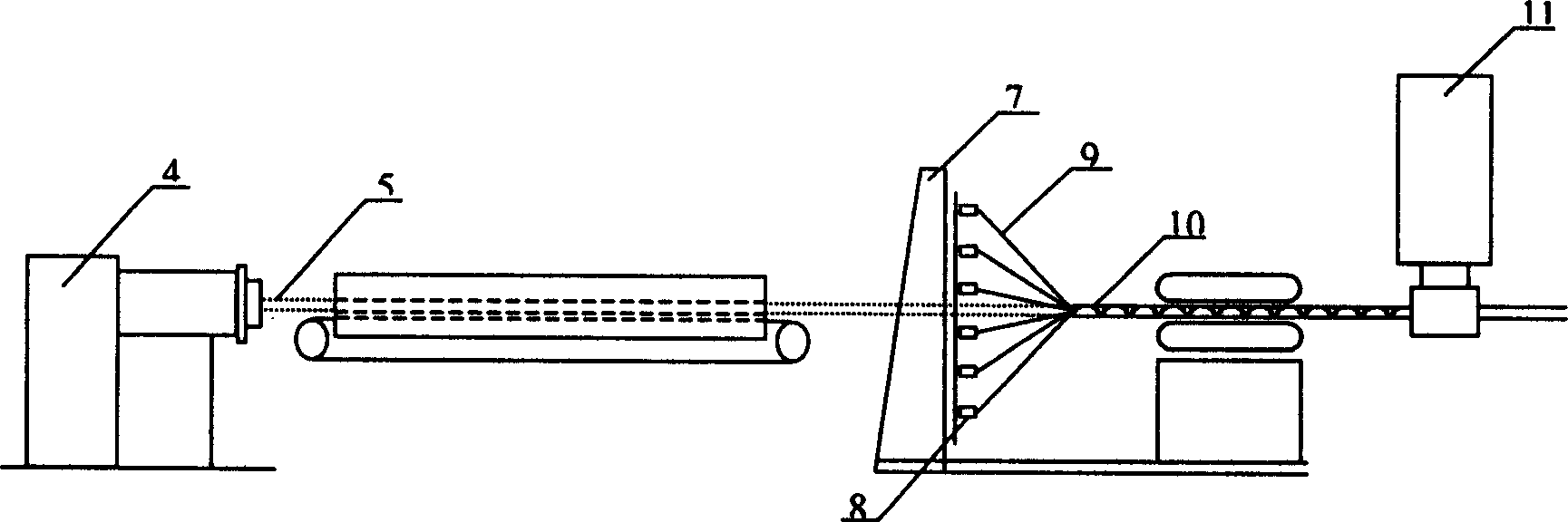

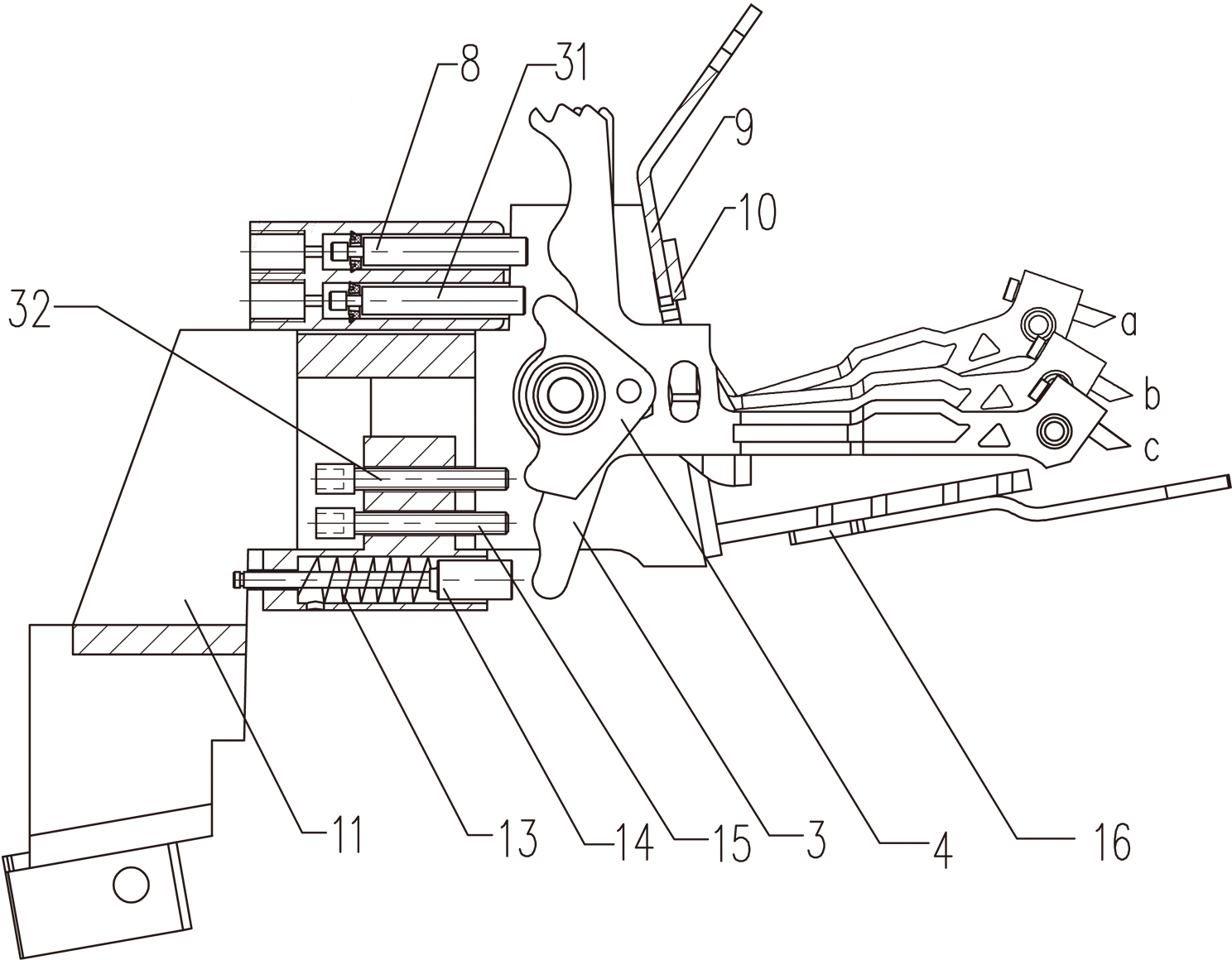

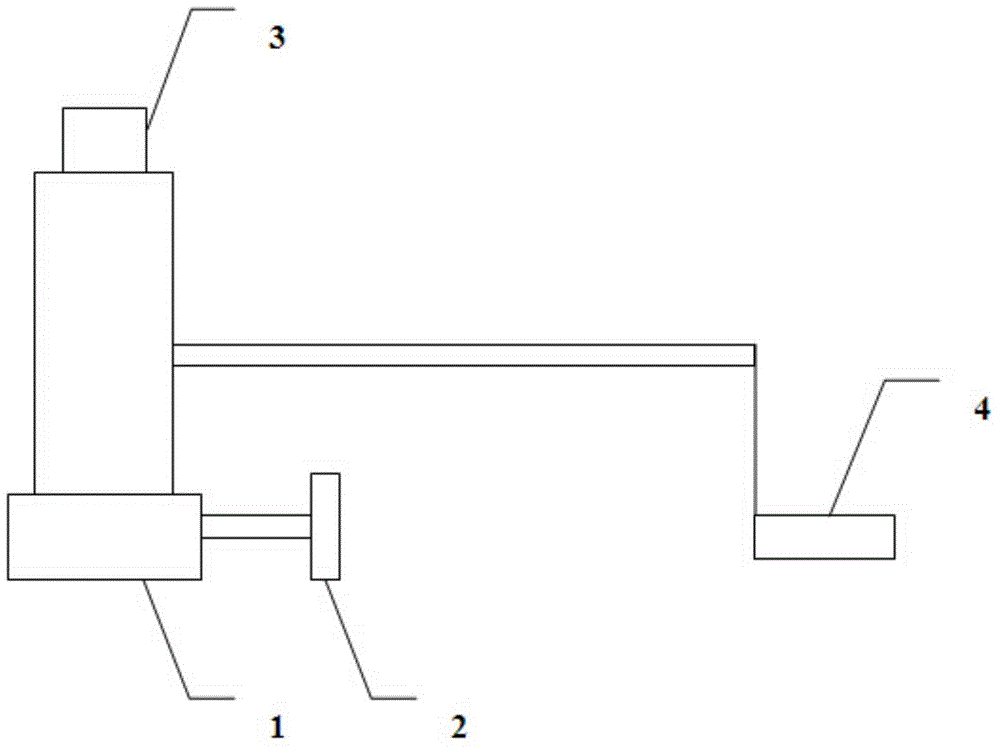

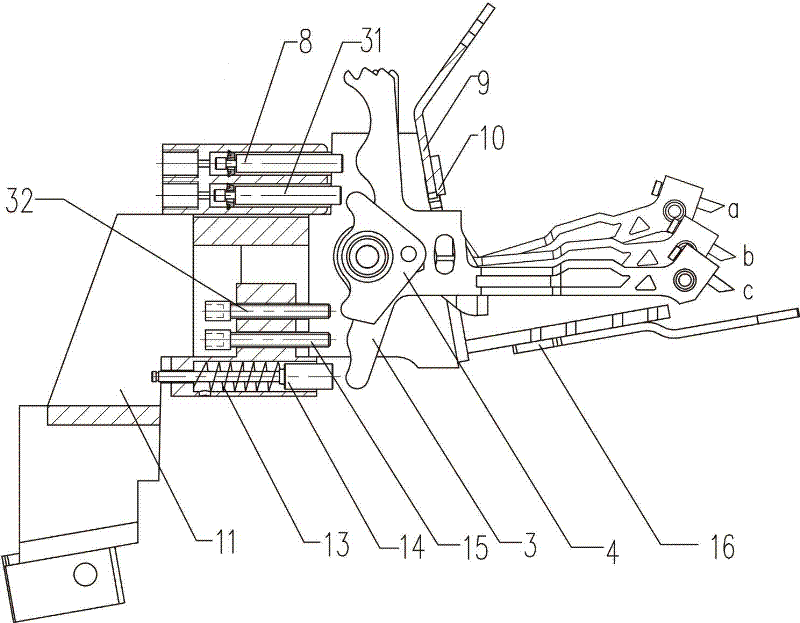

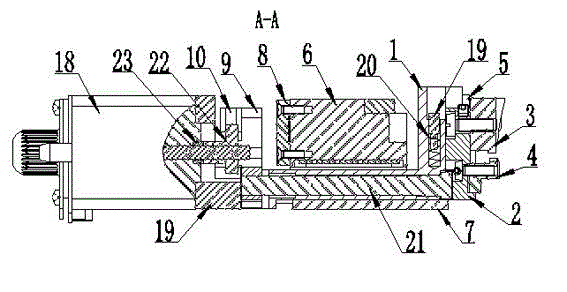

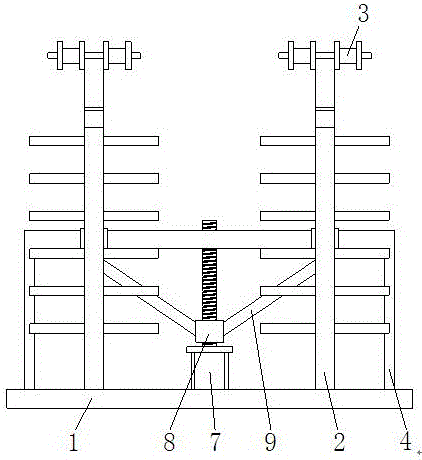

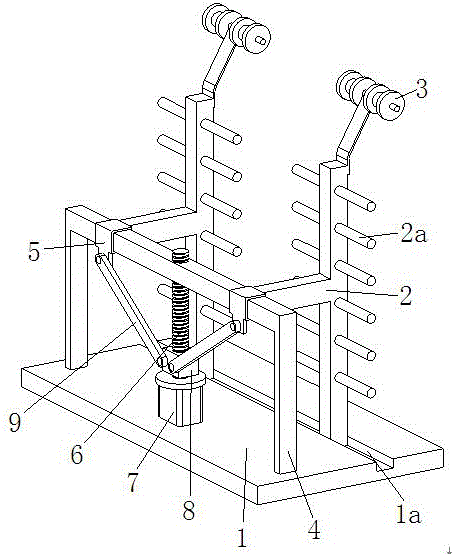

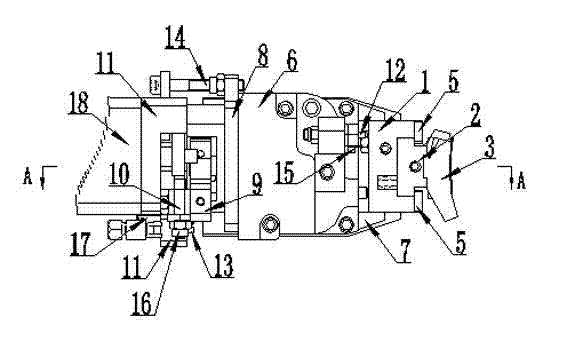

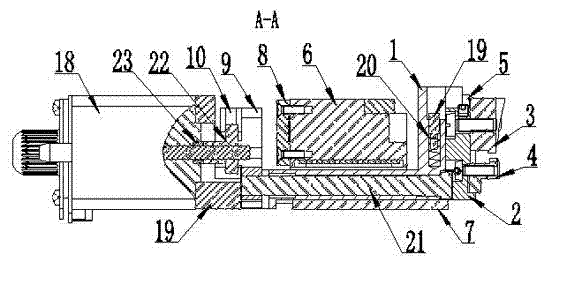

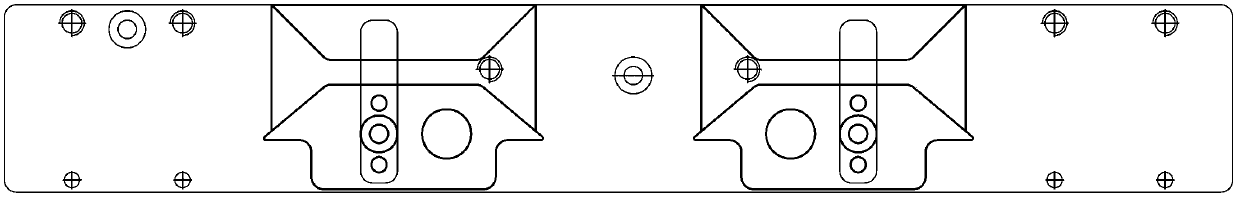

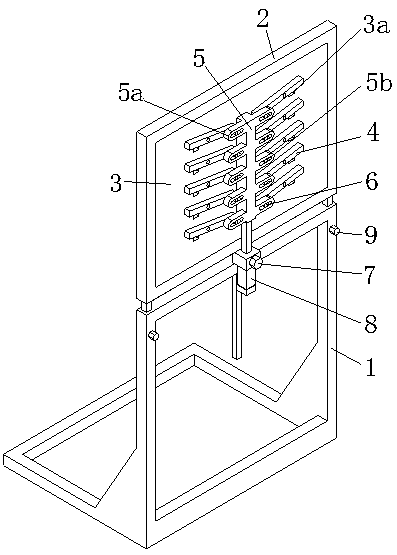

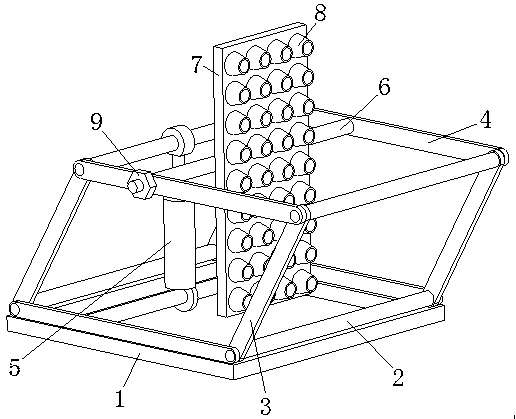

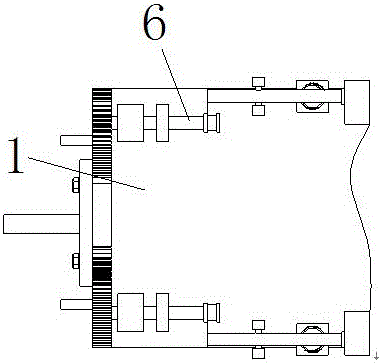

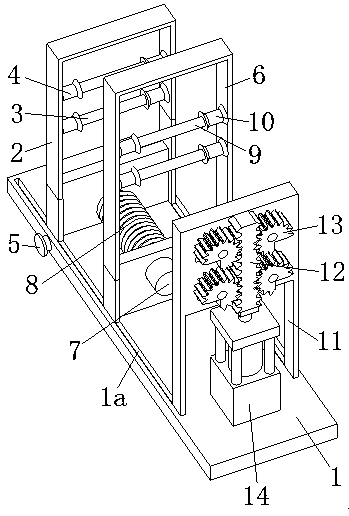

Test device of rotary electronic dobby

ActiveCN103018068BQuality assuranceGuaranteed weaving qualityStructural/machines measurementElectrical controlElectric control

A test device of a rotary electronic dobby belongs to the technical field of test devices special for textile machinery and comprises a dobby placing platform, a power transmission mechanism, an angle signal collection mechanism and a blade signal collection mechanism. A portal frame and a controller are arranged at one end of the dobby placing platform, and the controller is located on one side of the portal frame facing to the length direction of the dobby placing platform. The power transmission mechanism is arranged on the lateral portion of the dobby placing platform and is in electric control connection with the controller. The angle signal collection mechanism is arranged on the lateral portion of the dobby placing platform and is in transmission matching with the power transmission mechanism. The blade signal collection mechanism is used for collecting swinging position signals of blades of the dobby and is arranged on the portal frame and electrically connected with the controller. The test device of the rotary electronic dobby has the advantages of being accurate in heald lifting actions, excellent in reliability, good inn safety and strong in compatibility so as to ensure textile quality.

Owner:常熟纺织机械厂有限公司

Tying device for hosiery circular knitting machine

The invention discloses a tying mechanism for a hosiery circular knitting machine. The tying mechanism comprises an air valve seat, a suction port, an upper scissors mechanism, a thread guard mechanism, a thread pressing mechanism, a suction port thread guard mechanism and a thread clamping mechanism, wherein the above mechanisms are all mounted on a huff disc seat; disc scissors are arranged below the huff disc seat; and a huff disc is arranged below the disc scissors. the upper scissors mechanism mainly cooperate with the disc scissors for combined action; with the center point of the disc scissors as the circle point, under program control, the disc scissors rotate, and the upper scissors mechanism is fixed on the air valve seat and does not move; through mobile and static combination, a shearing force is generated to shear floating threads and redundant threads generated in the knitting process. By adopting the tying mechanism, the waste yarns and redundant threads shearing efficiency can be effectively improved, the machine fault rate is reduced, the maintenance cost is directly saved for users, and the production efficiency is greatly improved. The tying mechanism is simple in structure, and tidy and beautiful in appearance, can effectively improve the knitting efficiency of textiles, and ensures the appearance quality of the textiles.

Owner:NINGBO CIXING

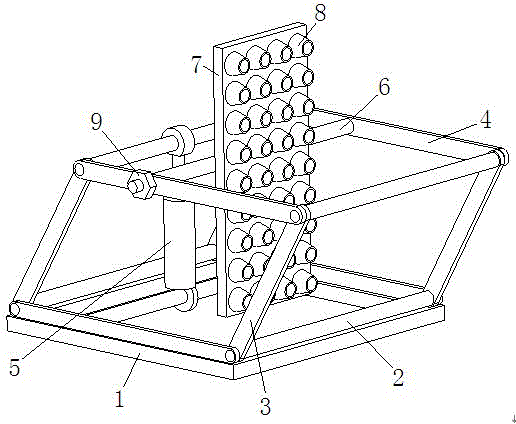

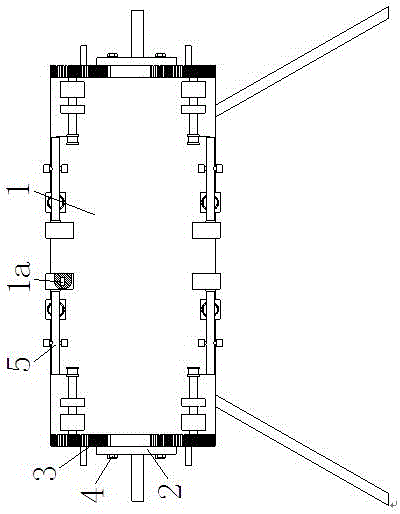

Filter screen thread guiding device

ActiveCN106521802AImplementation orientationImprove feeding efficiencyBraidHydraulic cylinderEngineering

The invention discloses a filter screen thread guiding device. The device comprises a pedestal. The left part and right part of the pedestal are all provided with connection rods. The front end and rear end of the connection rod are all provided with coupling rods. A positioning frame is placed above the pedestal. The pedestal is provided with a hydraulic cylinder. The positioning frame is provided with a positioning shaft. The outer wall of the positioning shaft is fixedly provided with a guiding plate. The right end of the guiding plate is evenly provided with conical pipe sleeves. The outer wall of the positioning shaft is provided with positioning screw nuts. The device has the advantages of being reasonable in design, having convenient usage, achieving the guiding of thread, enhancing thread feeding efficiency, ensuring weaving quality of filter screen, saving a huge amount of labor and material, having a folding feature, and being convenient to store.

Owner:WUHU HANGDA NETWORK IND CO LTD

A wire guiding device for a filter

ActiveCN106521802BImplementation orientationImprove feeding efficiencyBraidHydraulic cylinderEngineering

The invention discloses a filter screen thread guiding device. The device comprises a pedestal. The left part and right part of the pedestal are all provided with connection rods. The front end and rear end of the connection rod are all provided with coupling rods. A positioning frame is placed above the pedestal. The pedestal is provided with a hydraulic cylinder. The positioning frame is provided with a positioning shaft. The outer wall of the positioning shaft is fixedly provided with a guiding plate. The right end of the guiding plate is evenly provided with conical pipe sleeves. The outer wall of the positioning shaft is provided with positioning screw nuts. The device has the advantages of being reasonable in design, having convenient usage, achieving the guiding of thread, enhancing thread feeding efficiency, ensuring weaving quality of filter screen, saving a huge amount of labor and material, having a folding feature, and being convenient to store.

Owner:WUHU HANGDA NETWORK IND CO LTD

Yarn pressing device of computer flat-knitting machine

The invention provides a yarn pressing device of a computer flat-knitting machine. The computer flat-knitting machine includes a guide rail and a yarn nozzle base, wherein the yarn nozzle base is arranged on the guide rail in a left-and-right moving mode; the upper portion of the yarn nozzle base is fixedly provided with a pair of yarn nozzle base palping feet different in direction, the space between the pair of yarn nozzle base palping feet is configured into a shuttle changing sliding block cavity, the lower portion of the yarn nozzle base is provided with a yarn feeding nozzle guide rod, the lower portion of the yarn feeding nozzle guide rod is provided with a yarn feeding nozzle, and the yarn pressing device includes a yarn pressing plate base, a yarn pressing tongue plate fixing rod and a yarn pressing tongue plate; a yarn pressing tongue plate base is cooperated with the guide rail at the position corresponding to the front side of the yarn nozzle base in a sliding mode, the upper portion of the yarn pressing tongue plate base is fixedly provided with a pair of yarn pressing tongue plate base palping feet different in direction, the space between the pair of yarn pressing tongue plate base palping feet is configured into a direction-change block cooperation cavity, the upper end of the yarn pressing tongue plate fixing rod is fixed with the middle position of the side, back on to the guide rail, of the yarn pressing tongue plate base, the lower end of the yarn pressing tongue plate fixing rod stretches to the lower portion of the yarn pressing tongue plate base, and the yarn pressing tongue plate is fixed to the lower end of the yarn pressing tongue plate fixing rod. The weaving quality of a metal fiber fabric is ensured.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

Traction device for braiding polyester steel wire filter screen

The invention discloses a traction device for braiding a polyester steel wire filter screen. The traction device comprises a supporting frame, wherein sliding blocks are mounted at left and right ends of the supporting frame; racks are mounted at upper and lower ends of the sliding blocks; through holes are uniformly formed in the front end of the supporting frame; positioning nuts are mounted on the sliding blocks; positioning groups are symmetrically mounted at left and right parts of the supporting frame; each positioning group comprises a positioning unit; the positioning units are vertically symmetrically mounted on the supporting frame. The traction device for braiding the polyester steel wire filter screen has the advantages of reasonable structural design, convenience for utilization and the like; guidance for polyester yarns is realized, and the braiding quality of the filter screen is guaranteed; the processing efficiency of the filter screen is improved, and the production cost is reduced; meanwhile, the polyester yarns are positioned and tightly clamped through the positioning units, and the polyester yarns are convenient to feed, so that a lot of manpower and material resources are saved.

Owner:WUHU HANGDA NETWORK IND CO LTD

A feeding device for flat yarn

The invention discloses a loading device for a flat filament. The loading device comprises a support plate, wherein a chute is formed in the upper end of the support plate, a slide frame I is mounted on the right part of the chute, connecting shafts I are uniformly mounted at the upper part of the slide frame I, and guide wheels I are uniformly mounted on the outer walls of the connecting shafts I; a slide frame II is mounted in the middle of the chute, connecting shafts II are uniformly mounted at the upper part of the slide frame II, and guide wheels II are uniformly mounted on the outer walls of the connecting shafts II; and a connecting plate is mounted on the left part of the support plate, a rack is mounted in the middle of the connecting plate, limiting blocks are mounted on the front end of the connecting plate, and an air cylinder is mounted at the upper end of the support plate. The loading device has the advantages of reasonable structural design, convenience in maintenance and the like; by guiding through the guide wheels I and the guide wheels II, the tension degree of the flat filament is controlled, and the weaving quality of the flat filament is guaranteed; and by utilizing the rotatable limiting blocks, the flat filament is clamped and fixed, the manual loading is facilitated, and a lot of manpower and material resources are saved.

Owner:WUHU HANGDA NETWORK IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com