A feeding device for ore filter wire

A technology of filter screen and silk thread, which is applied in the direction of textiles, papermaking, braided fabrics, etc., can solve the problems of unguaranteed feeding accuracy of raw materials, wire winding, and affecting product quality, so as to save manpower and material resources, reasonable structural design, and ensure weaving quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

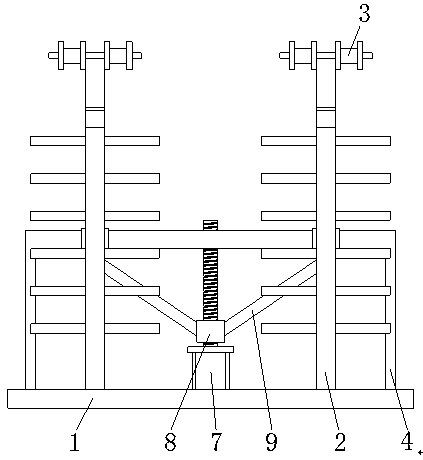

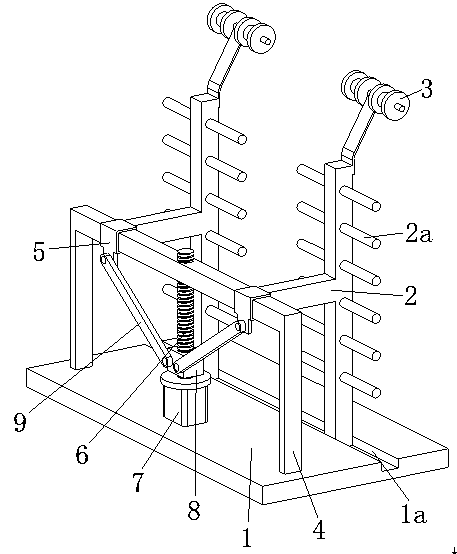

[0014] like Figure 1 to Figure 2 As shown, a feeding device for ore filter screen silk thread includes a lower base plate 1, the upper end of the lower base plate 1 is provided with a sliding groove 1a, and the left and right parts of the sliding groove 1a are equipped with a sliding frame 2, Guide wheels 3 are uniformly installed on the upper end of the sliding frame 2 . During use, silk thread all utilizes corresponding guide wheel 3 to guide.

[0015] The rear portion of the lower base plate 1 is equipped with a support frame 4, and the left and right parts of the support frame 4 are equipped with sliding blocks 5 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com