A feeding device for flat yarn

A flat yarn, No. 1 technology, applied to the feeding device for flat yarn in paper drying net, and the feeding device for flat yarn, to achieve the effect of convenient manual feeding, saving manpower and material resources, and ensuring the quality of weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

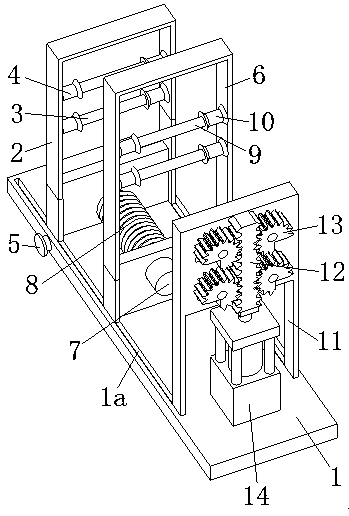

[0018] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

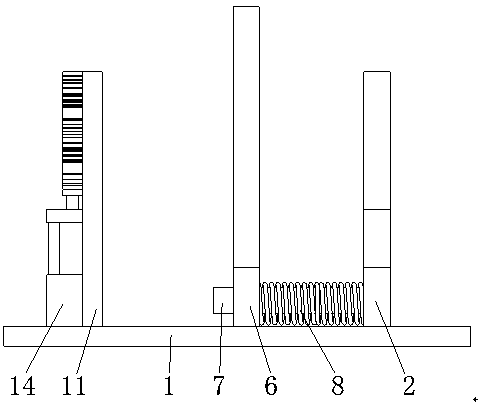

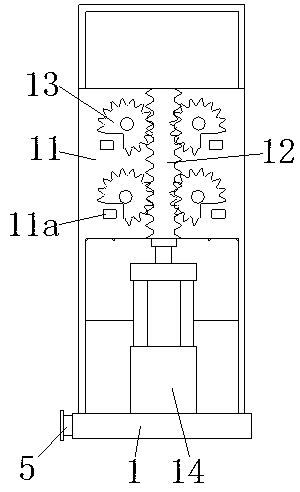

[0019] like Figure 1 to Figure 4 As shown, a feeding device for flat wire includes a support plate 1, the upper end of the support plate 1 is provided with a slideway 1a, the right part of the slideway 1a is equipped with a No. 1 sliding frame 2, and the No. The top of the frame 2 is evenly equipped with a No. 1 connecting shaft 3 arranged longitudinally, a No. 1 guide wheel 4 is evenly installed on the outer wall of the No. 1 connecting shaft 3, and a positioning bolt 5 is installed on the No. 1 sliding frame 2. The middle part of the slideway 1a is equipped with a No. 2 sliding frame 6, and the left end of the No. 1 slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com