Tying device for hosiery circular knitting machine

A tie-in device and knitting machine technology, applied in the field of knitting machinery, can solve problems such as lowering yield rate, damage to circular knitting machines, wear and tear of huff needles and knitting needles, etc., so as to reduce machine failure rate, save maintenance costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

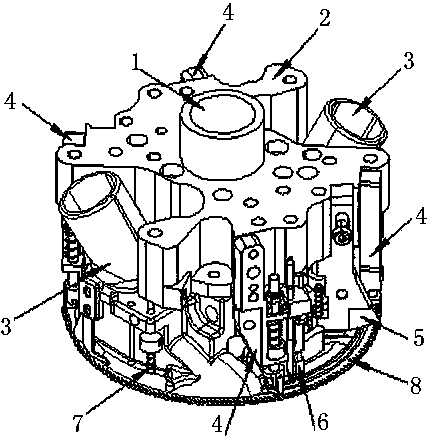

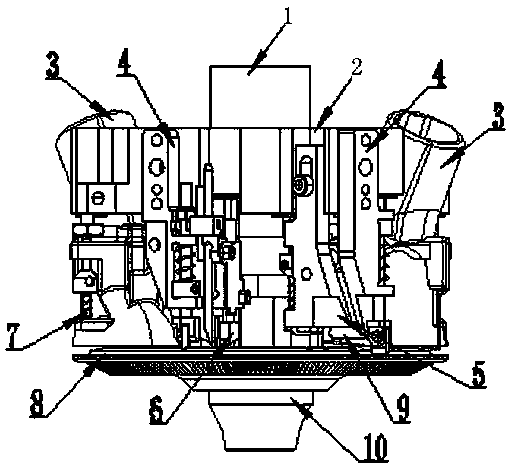

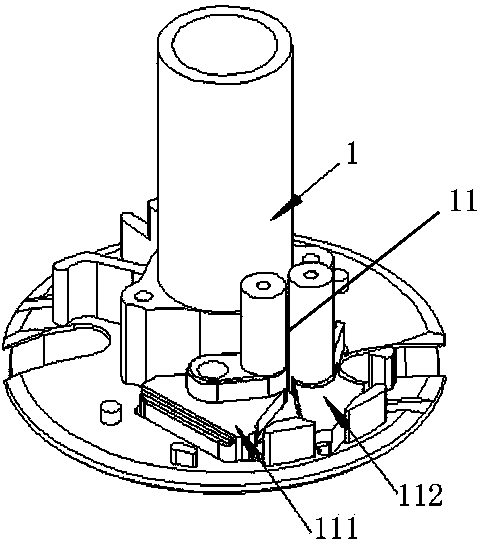

[0033] See attached picture. This embodiment includes a valve seat 2, a suction port 3, an upper scissors mechanism 4, a thread blocking mechanism 5, a thread pressing mechanism 6, a suction port blocking mechanism 7, and a thread clamping mechanism 9, and the above mechanisms are all installed on a half disk seat 1, there is a disc scissors 8 below the half disc seat, and a half disc 10 below the disc scissors 8; the half disc seat 1 is in the shape of an inverted umbrella, with a second A groove 101 and a second groove 102 also have a first protrusion 103, a second protrusion 104, a third protrusion 105, and a fourth protrusion 106 on the umbrella surface of the half disk base, and the protrusions All are on the trace of the wire; there is a chamfer 107 on the edge of the umbrella cover of the half disk seat; the lower surface of the umbrella surface of the half disk seat 1 cooperates with the disc scissors 8.

[0034] There is a switch knife mechanism 11 on the half plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com