Floating upright post protective net structure

A technology for protective nets and columns, applied in the field of protective nets, can solve the problems of limited practical effect of protective columns, consumption of rockfall kinetic energy, and failure of fixed columns to buffer, etc., to achieve good rockfall impact resistance, improve adaptability, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

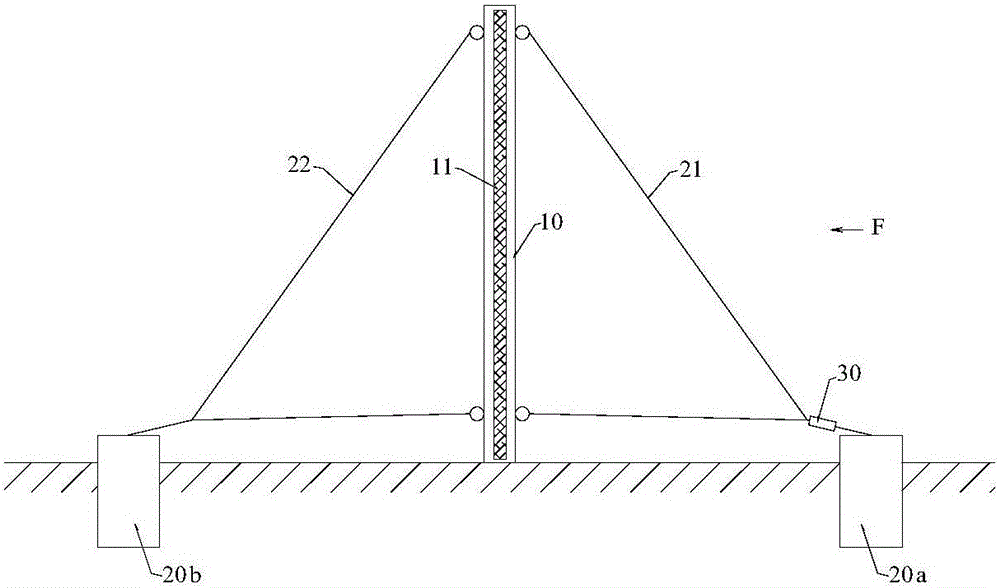

[0014] In this specification, in order to accurately describe and avoid ambiguity, the side of the column 10 and the protective net surface 11 facing the rockfall impact direction F is defined as the "front side", such as "front side anchoring member 20a", "front side steel The other side is defined as the "rear side", such as "rear side anchoring member 20b", "rear side steel cable 22" and so on.

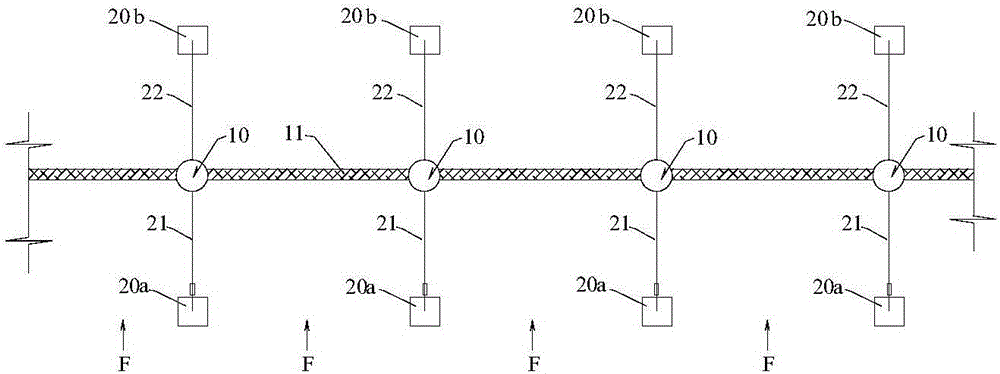

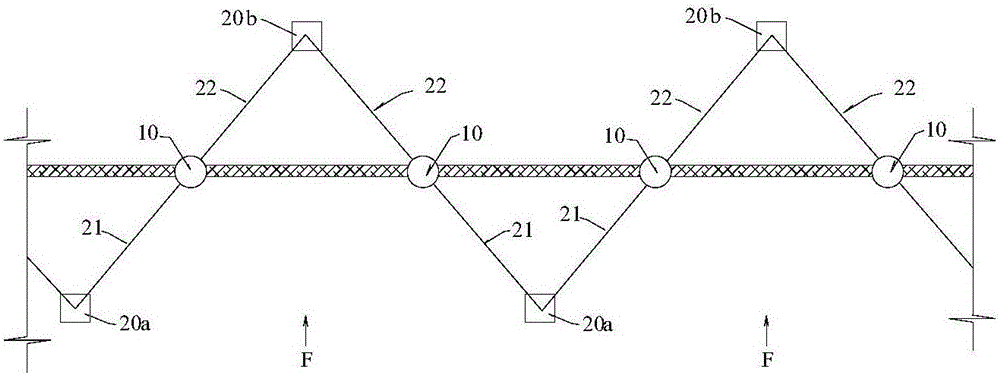

[0015] refer to figure 1 with figure 2 , the structure of the floating column protective net of the present invention includes columns 10 arranged in rows and a protective net body 11 suspended and fixed thereon. A front anchoring member 20a and a rear anchoring member 20b integrally connected with the ground are arranged on both sides of the column 10 . Each column 10 is suspended above the ground by a pair of front side steel cables 21 and rear side st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com