Connecting structure for floor drain core and floor drain body

A technology for connecting structures and cores, applied in drainage structures, waterway systems, water supply devices, etc., can solve the problems of small force range, troublesome operation, easy to break the core 2', etc., to simplify the slot structure and save manpower Cost and effect of simplifying the machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

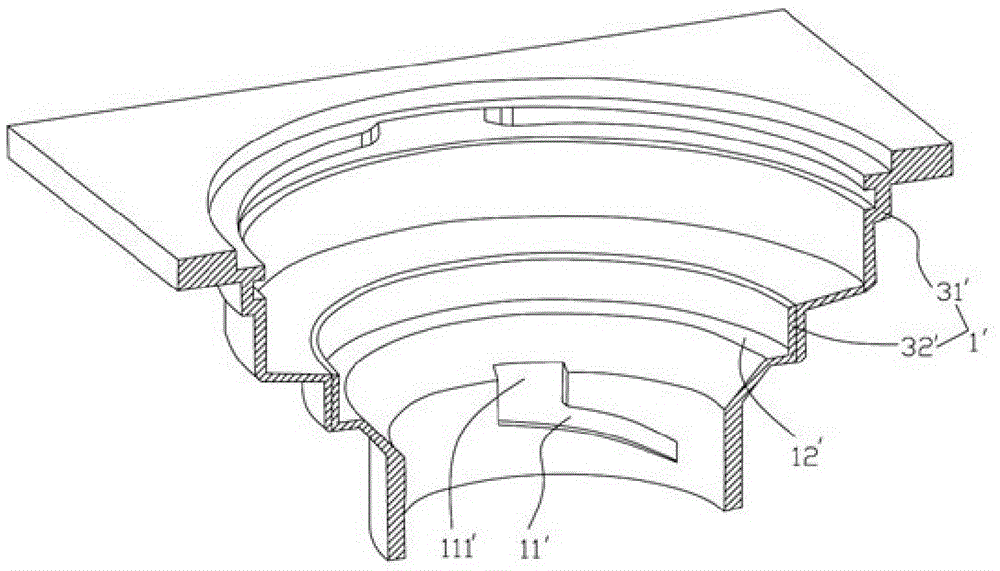

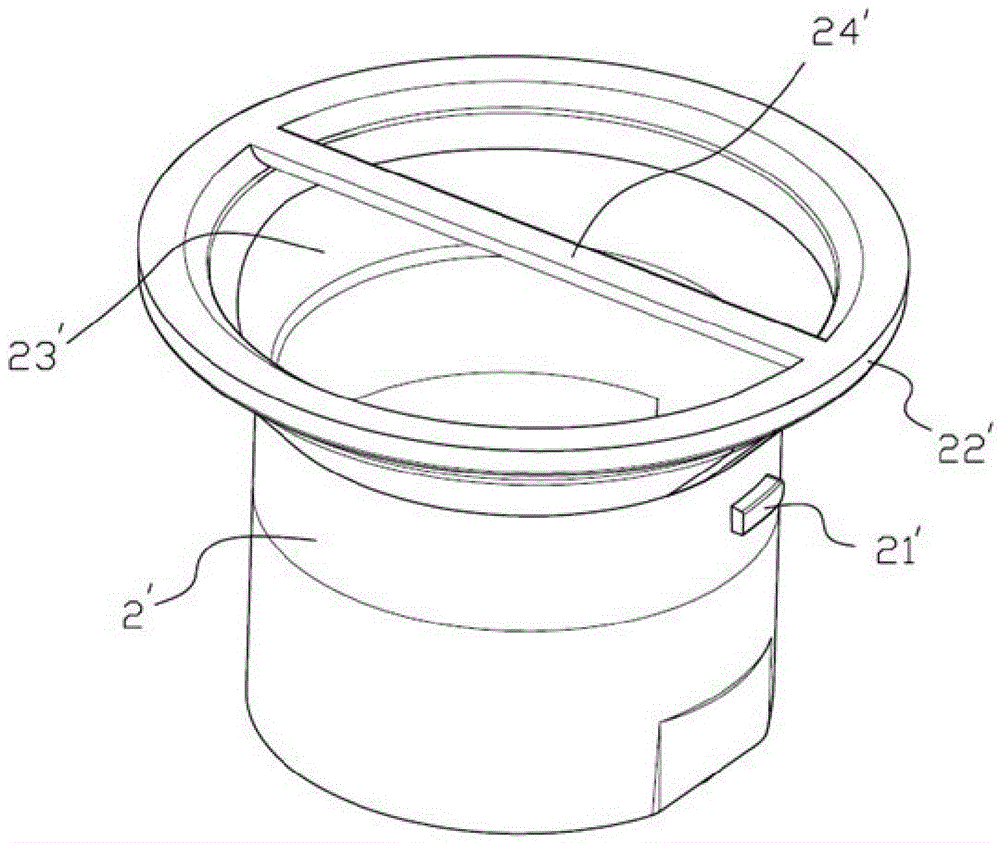

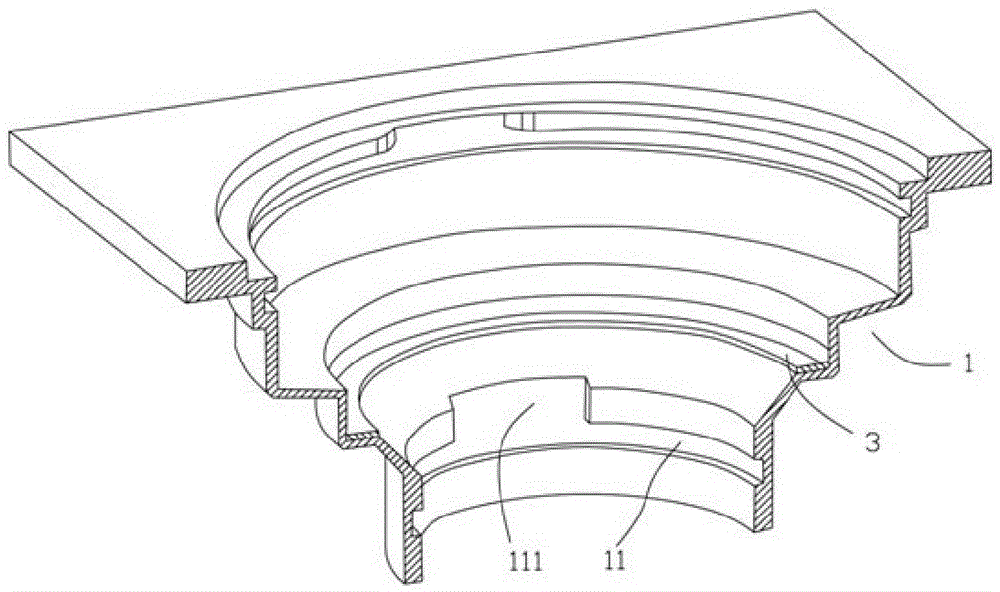

[0027] Such as image 3 with 4 As shown, a connection structure between the floor drain core and the body, including the floor drain body 1 and the core 2, the inner wall of the floor drain body 1 is provided with a card slot 11, and the outer wall of the core 2 is provided with several protrusions that can be engaged with the card slot 11. Block 21.

[0028] The clamping groove 11 is an annular groove of equal depth, and an upper notch 111 is provided above the annular groove at a position corresponding to each core protrusion 21 . When the annular groove structure of the card groove 11 is connected with the bump 21, it can be assembled in two directions. As long as the bump 21 is correspondingly snapped into the corresponding upper notch 111, the bump 21 can be snapped into it by turning counterclockwise or clockwise. The snap connection between the core 2 and the body 1 is realized in the annular groove. Even if debris enters the guide groove 11 in actual use and makes on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com