Tunnel lining trolley

A technology for lining trolleys and tunnels, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of insufficient strength, loose concrete structure on the inner wall of the tunnel, weak structural strength, etc., and achieve the effect of solid concrete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

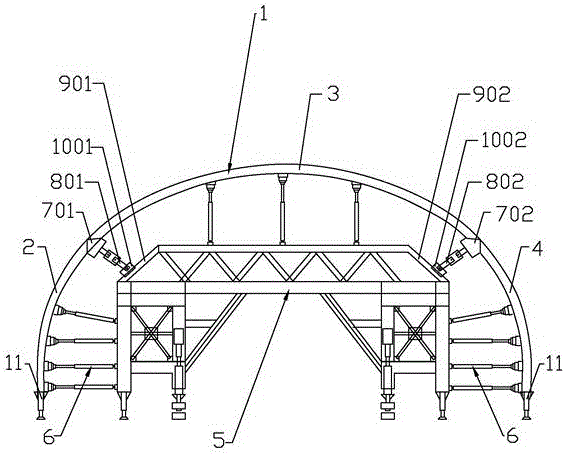

[0018] Attached below figure 1 The present invention is described in further detail.

[0019] as attached figure 1 As shown, the present invention is a tunnel lining trolley, which includes an arc-shaped formwork unit 1, a skeleton unit 5, and an adjustment support unit 6; the formwork unit 1 includes first side formworks arranged in sequence along the arc direction Group 2, top formwork 3 and second side formwork group 4; the adjustment support unit 6 is arranged between the skeleton unit 5 and the formwork unit 1, which is configured to be able to actuate the first side formwork group according to the size of the tunnel section 2. The top formwork 3 and the second side formwork group 4 move outwards so that they fit the lining of the tunnel; the inner surface of the formwork unit 1 between the first side formwork group 2 and the top formwork 3 is provided with a The first gap 701 of the skid, one side of the skeleton unit 5 is connected with a first support member 801 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com