Inflator air nozzle assembly convenient to use

A pump and nozzle technology, applied in the direction of pump components, variable capacity pump components, liquid variable capacity machinery, etc., can solve the problems of poor tightening force of tire gas nozzles, inconvenient use, and inability to be used for high-pressure inflation. Achieve the effect of convenient and quick use and lengthen the force arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

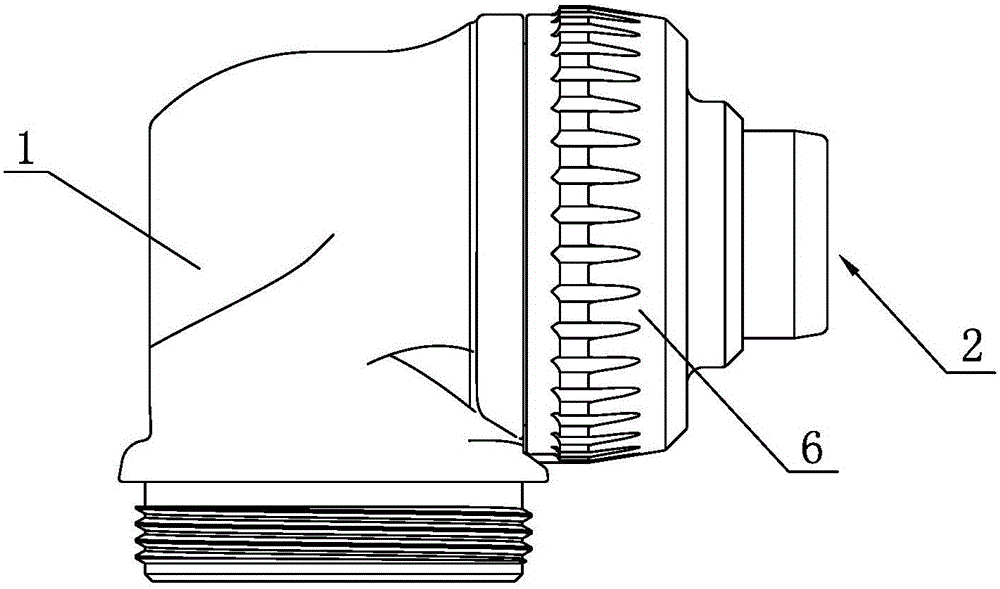

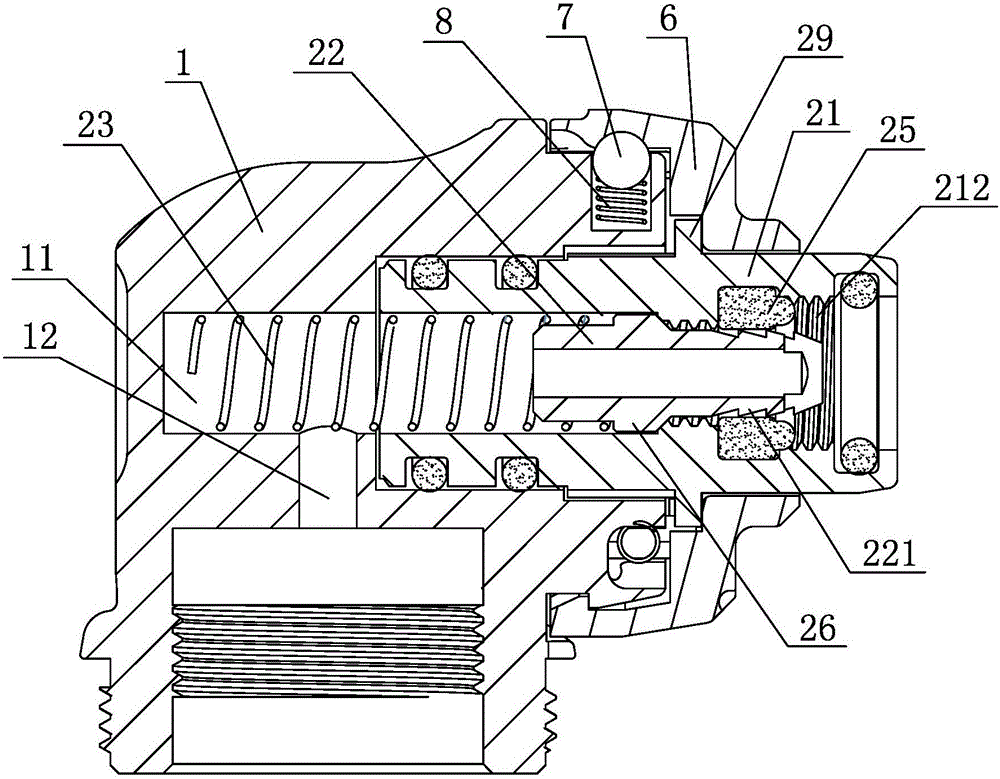

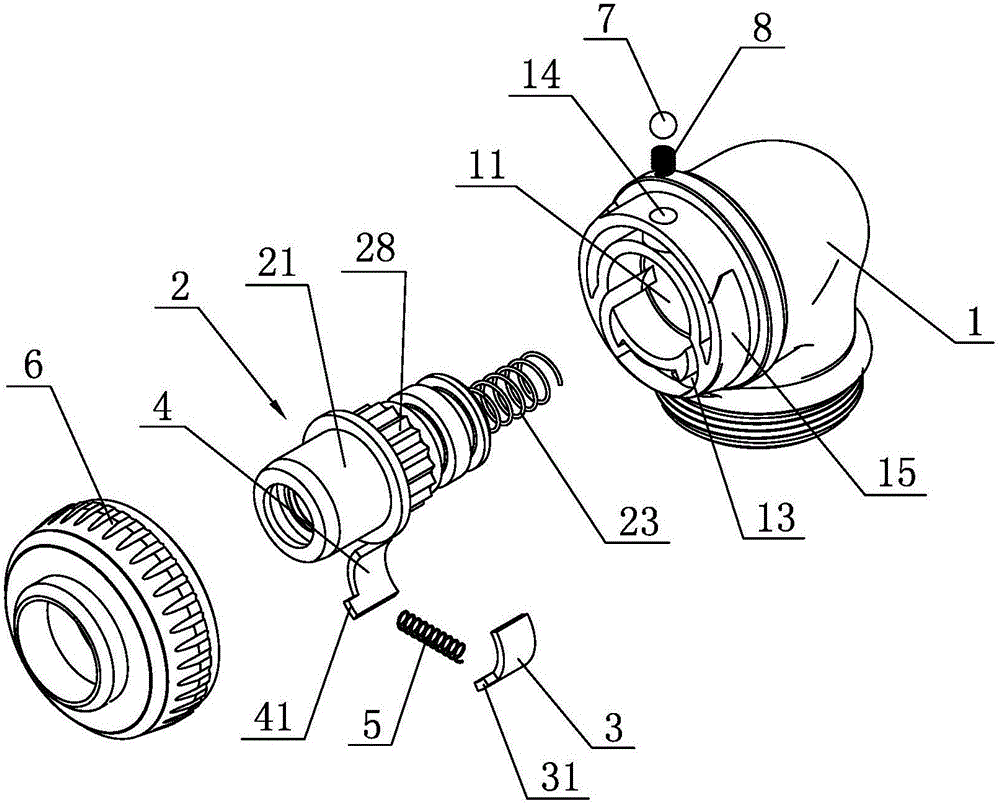

[0025] Embodiment 1: As shown in the figure, an easy-to-use air pump nozzle assembly includes a housing 1 and a valve core assembly 2 for threaded connection and fixation with the tire valve, the housing 1 and the gas outlet end of the pump (Fig. (not shown in ) is fixedly connected, the valve core assembly 2 includes a core body 21, a top core 22 and a third spring 23, the housing 1 is provided with a first inner chamber 11, and the core body 21 is sealed and plugged into the first inner chamber 11 , the shell 1 is provided with an air channel 12 for communicating with the first inner chamber 11 and the outlet end of the pump (not shown in the figure), and the core 21 is provided with a second inner chamber 211 communicating with the first inner chamber 11 , The top core 22 is located in the second inner cavity 211, the third spring 23 is connected between the top core 22 and the inner bottom of the first inner cavity 11, and the wall of the second inner cavity 211 is integral...

Embodiment 2

[0027]Embodiment 2: other structures are the same as Embodiment 1, the difference is that the ratchet transmission mechanism includes a ratchet, and the outer peripheral surface of the core body 21 is integrally provided with a ratchet 28, the ratchet is hinged in the shell 1, and the ratchet The pawl is engaged with the ratchet wheel 28, and when the housing 1 is rotated, the pawl pushes the core body 21 to rotate in one direction, and the core body 21 and the tire air nozzle are tightened and fixed.

[0028] In the above embodiment, the air nozzle core assembly 2 can also be a non-universal air nozzle, such as an American-style air nozzle that only matches the American-style tire air nozzle, or a French-style air nozzle that only matches the French-style tire air nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com