A one-way blocking condensate fluid dripping backflow drawing device

An extraction device and condensation reflux technology, applied in the field of one-way barrier condensate fluid dripping and reflux extraction device, can solve the problems of product back-mixing and deterioration loss, household hazards, dripping on flames, etc., to reduce environmental pollution and save energy Reliable and practical effect of energy and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

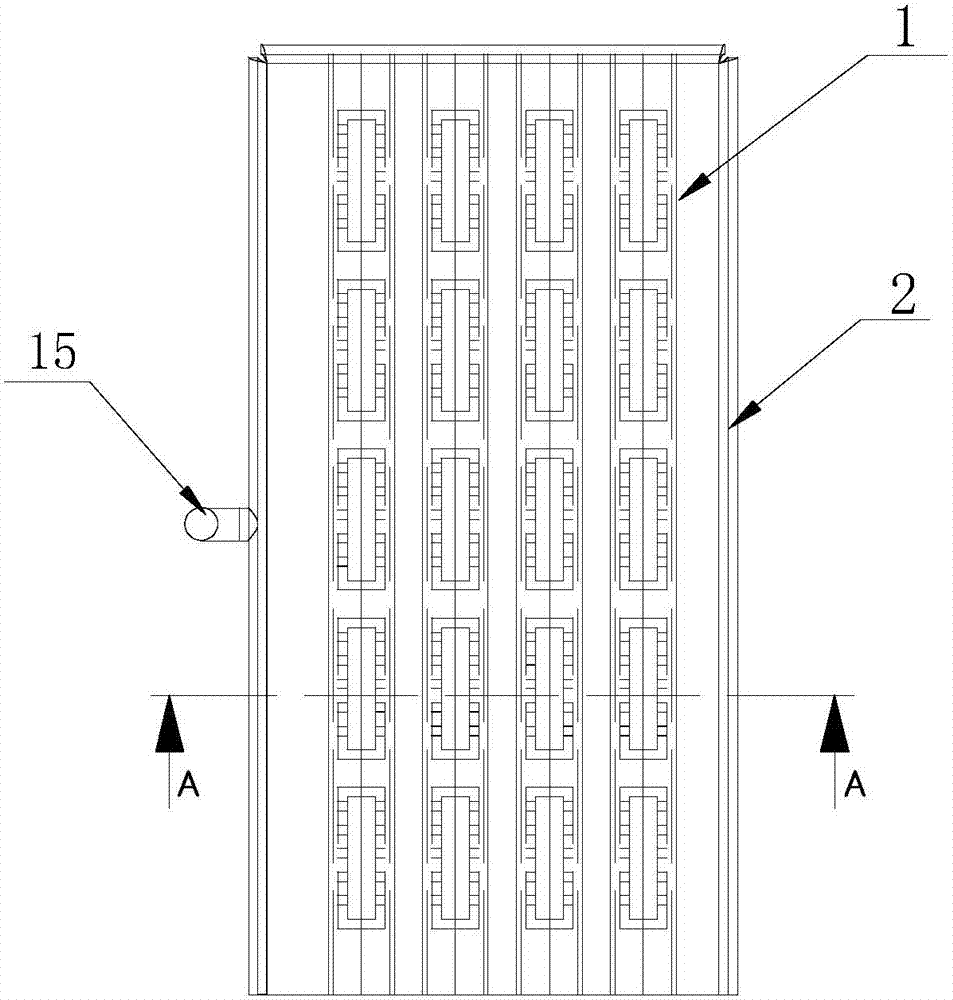

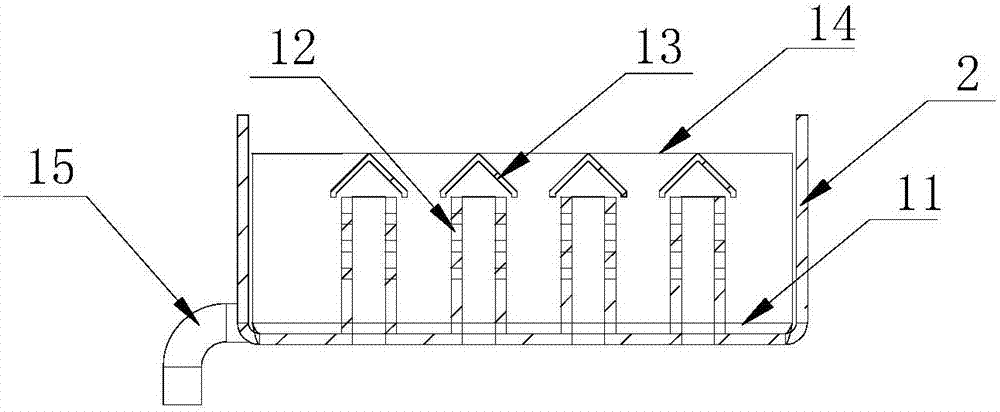

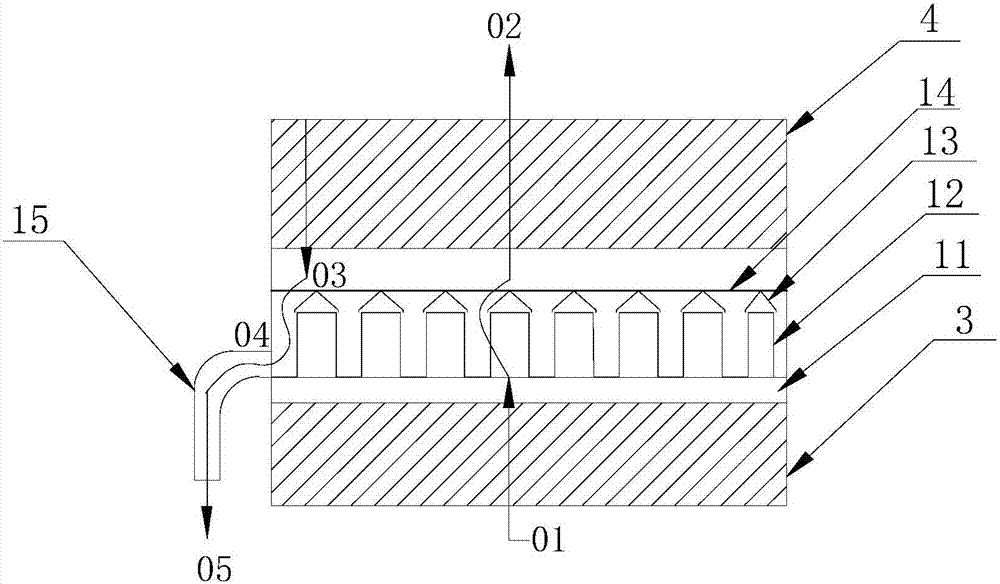

[0020] see Figure 1-3 , a one-way blocking condensate fluid dripping backflow drawing device provided by the present invention includes a condensate backflow assembly 1 and a metal shroud 2 for closing the condensate backflow assembly 1, and the condensate backflow assembly 1 includes densely punched holes The metal bottom plate 11, the fluid passage pipe 12 welded with the punching position, the metal sheet shell 13 covering the top of the fluid passage pipe 12, the metal mesh 14 fixed on the metal sheet shell 13, and the discharge pipe 15 for discharging condensed fluid .

[0021] When in use, the condensed fluid dripping reflux draw-out device is assembled between two heat exchangers, when some kind of upward high-temperature gas containing water vapor passes through the first layer of heat exchanger 3, and then passes through the densely distributed on the metal bottom plate 11 After the fluid channel pipe 12 passes through the metal mesh 14, it enters the second layer h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com