Wind power gear box fault diagnosis method

A wind power gearbox and fault diagnosis technology, which is applied in the testing of machine gear/transmission mechanism, the use of electrical devices, the use of electromagnetic means, etc., can solve problems such as difficult to detect fault information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

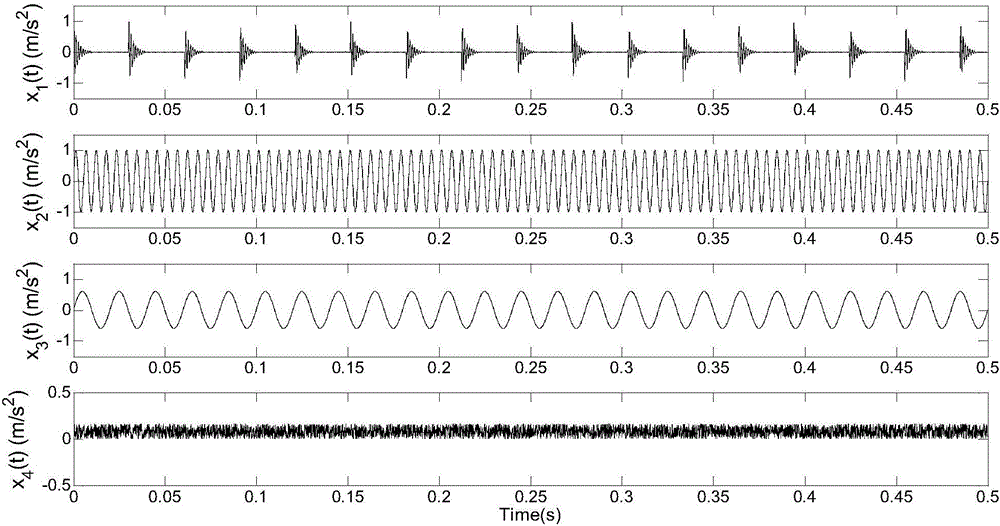

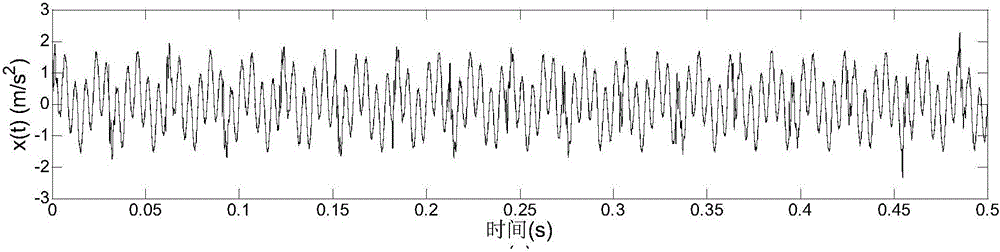

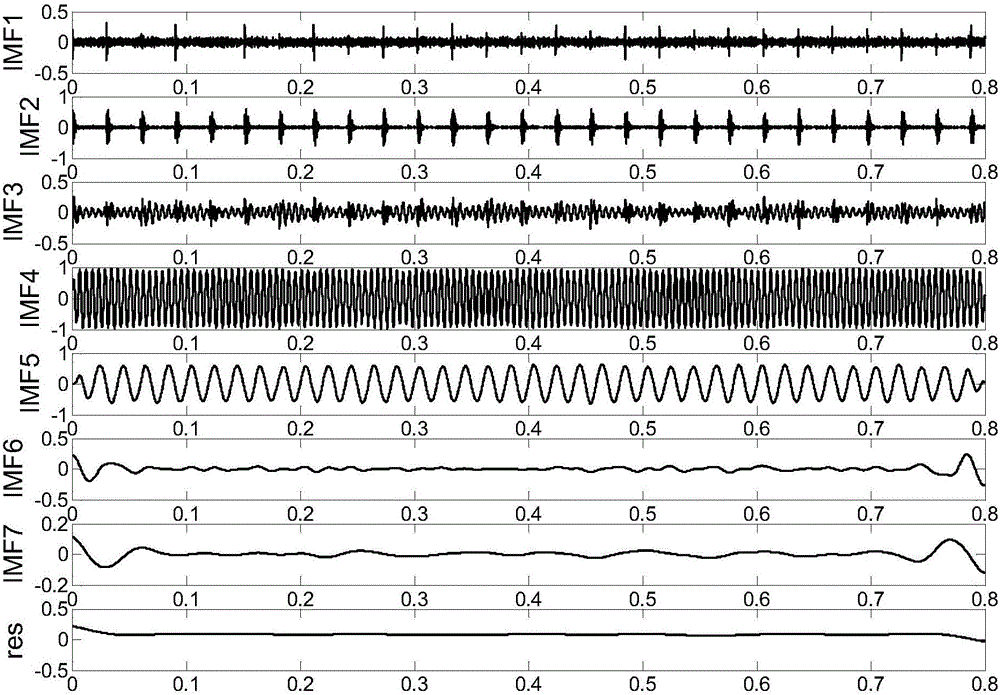

[0041] The gearbox fault diagnosis method is based on the vibration signal generated during the operation of the gearbox. During the operation of the gearbox, no matter whether there is a fault or not, there will be a vibration signal, but there are different differences between the vibration signal when there is no fault and when there is a fault. When the gearbox is not faulty, the frequency components of the vibration signal are mainly the meshing frequency of the gear and the natural frequency of the bearing itself. When the gears and bearings in the gearbox are faulty, the shock effect will be generated during the operation of the gearbox, which will change the vibration signal. At this time, the frequency components of the vibration signal include not only the meshing frequency of the gear and the natural frequency of the bearing itself, but also the vibration signal. It also increases the slew frequency of the part where the faulty part is located.

[0042] The vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com