Ductile cast iron pipe conveying device

A technology for ductile iron pipes and handling devices, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of damage to the outer surface of ductile iron pipes, damage to the appearance of ductile iron pipes, and the absence of redundant equipment, etc., to achieve The effect of preventing follow-up, wide application range, and convenient and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

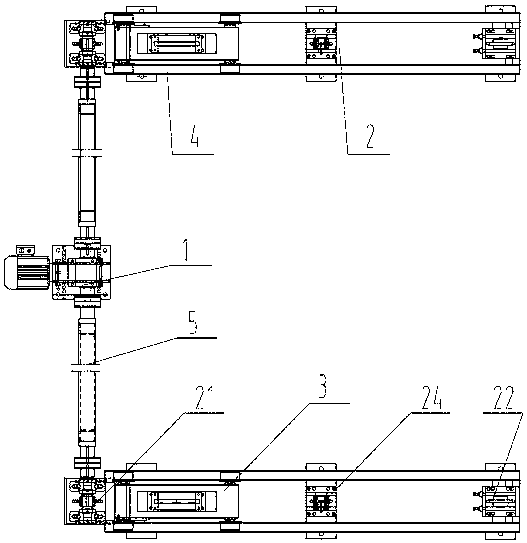

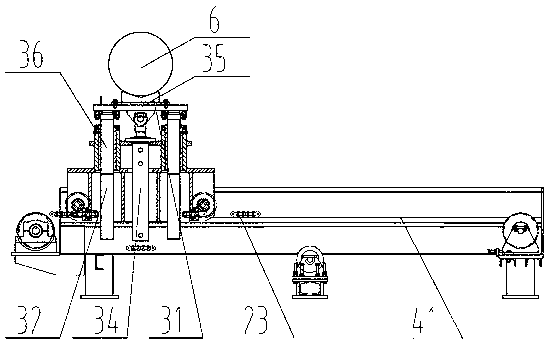

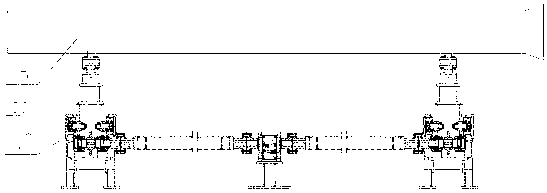

[0024] Such as Figure 1 to Figure 3 Shown is the first embodiment of the ductile iron pipe 6 handling device of the present invention, which includes a drive motor 1 and two sets of fixed chassis 4 arranged in parallel, each set of fixed chassis 4 is equipped with a transport vehicle 3 and a transmission mechanism 2 The transport vehicle 3 is provided with a support frame 31 for supporting the ductile iron pipe 6, and the transport vehicle 3 is slidingly connected to the fixed chassis 4; the transmission mechanism 2 is connected between the output end of the drive motor 1 and the transport vehicle 3. The driving motor 1 of this embodiment is arranged between two sets of fixed base frames 4 , and a connecting shaft 5 is connected between the driving motor 1 and the transmission mechanism 2 .

[0025] During the implementation of this embodiment, the ductile iron pipe 6 is placed on the transport vehicle 3 through the support frame 31, and the transport vehicle 3 slides on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com