Primary coil of CVT intermediate transformer and manufacturing method of primary coil

A manufacturing method and secondary coil technology, applied in the field of transformer manufacturing, can solve the problems of high layer insulation requirements, high interlayer voltage of coils, and difficulty in handling coils by hand, so as to improve the interlayer dielectric strength, reduce the interlayer voltage, and reduce the local The effect of discharge levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

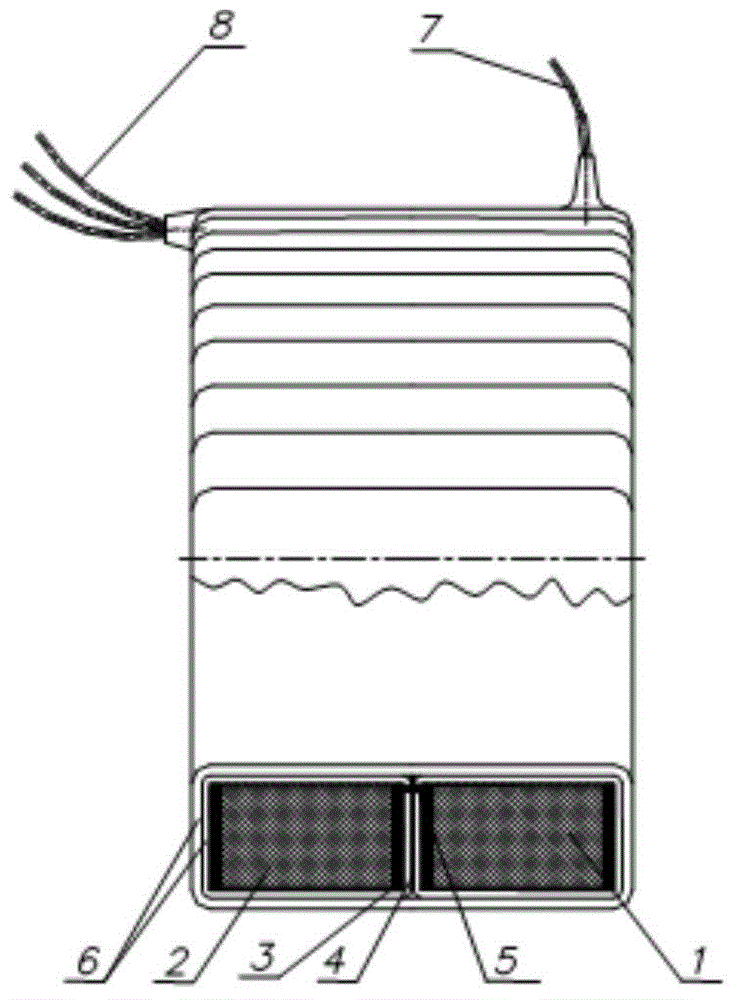

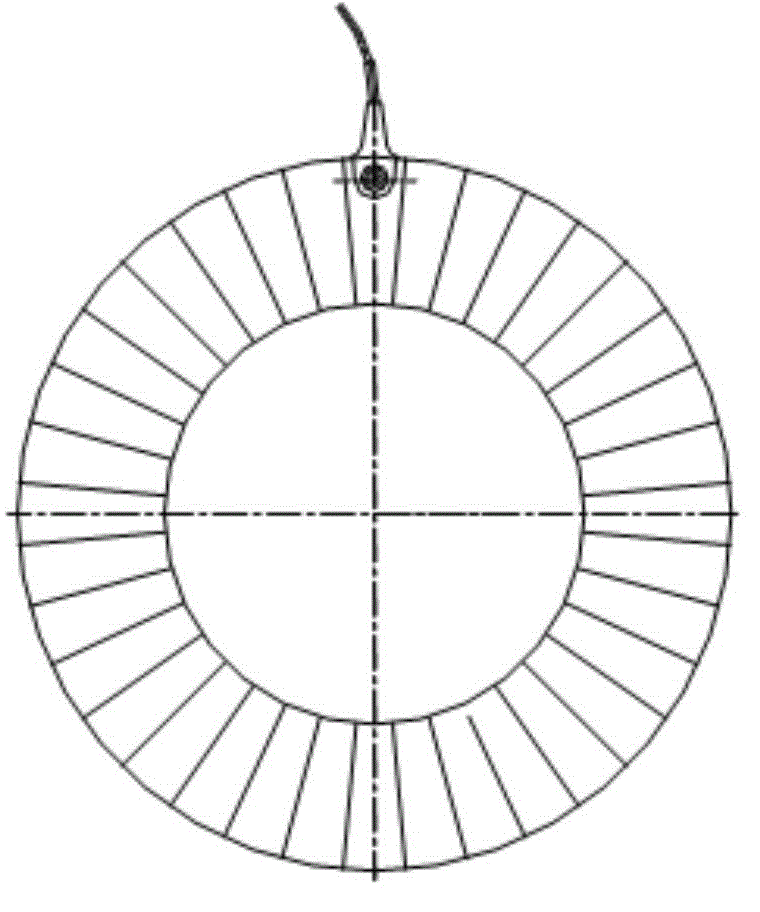

[0019] Such as figure 1 , 2 As shown, the primary coil of a CVT intermediate transformer of the present invention has two line segments, that is, line segment 1 and line segment 2 with taps arranged in parallel. Line segment 1 and line segment 2 with taps have independent insulating layers. The line segment with an independent insulation layer is placed between the line segment 1 and the line segment 2 with a tap. The line segment 4 is placed between the line segment 1 and the line segment 2 with a tap.

[0020] The separate insulating layers of line segment 1 and line segment 2 with taps are provided with a general insulating layer.

[0021] The manufacturing method of the CVT intermediate transformer primary coil of the present invention comprises the following steps:

[0022] Line segment 1 and line segment 2 with taps are wrapped with insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com