Pull-out guide for movable furniture parts

A technology for pulling out guides and furniture parts, applied in furniture parts, home appliances, bearings for linear motion, etc., can solve problems such as limiting the bearing capacity of pulling out guides, and achieve the effect of high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

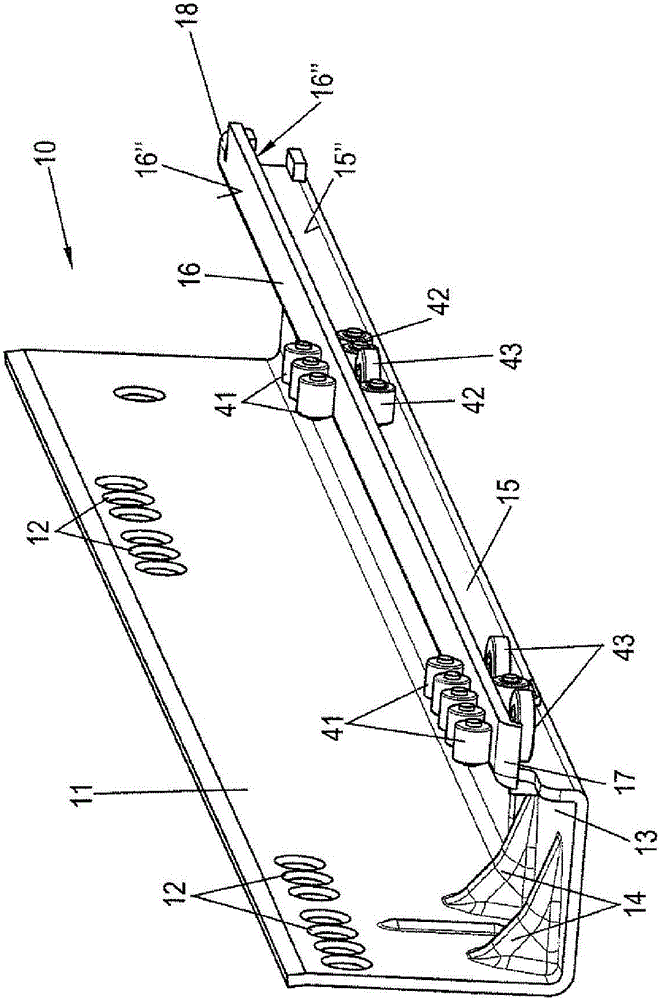

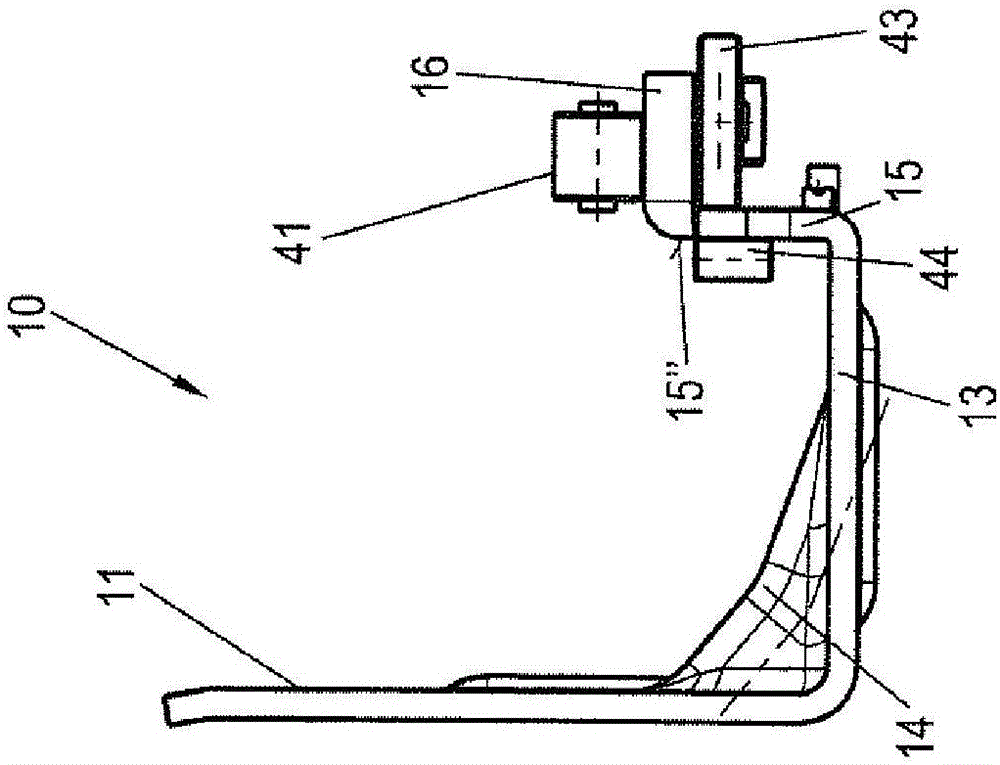

[0027] Two exemplary embodiments of the pull-out guide are described in more detail in the figures described below. figure 1 to 8 relate to the first exemplary embodiment, Figure 9 A second exemplary embodiment is shown, which is modified with respect to the first. In all figures, the same reference symbols designate the same or identically acting components.

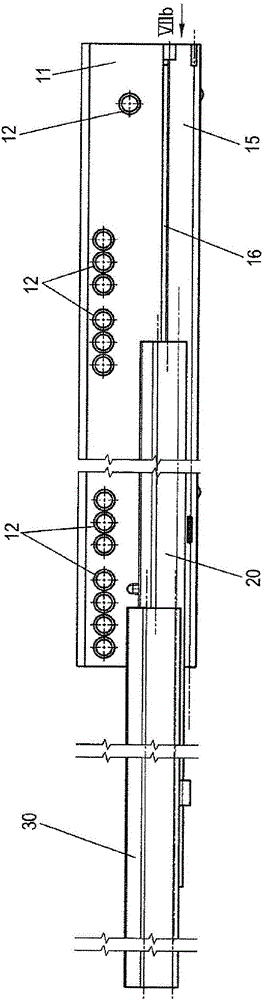

[0028] figure 1 A side view of the first exemplary embodiment of the pull-out guide is schematically shown in a partially extended position. The pull-out guide has three guide rails: a main rail 10 , a middle rail 20 , and a slide rail 30 .

[0029] The middle rail 20 is guided such that it is in each case by means of roller-shaped rolling elements ( figure 1 Not shown in ) is displaceable relative to the main body rail 10 and relative to the slide rail 30. The rolling elements used are preferably held in a rolling element cage. Each pair of rails (main rail 10 / middle rail 20 or middle rail 20 / sliding rail 30) ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com