Intraocular lens assembly

A lens and component technology, applied in the field of intraocular lens components, can solve problems such as residual errors, inability to fully correct optical errors, and inability to achieve normal refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

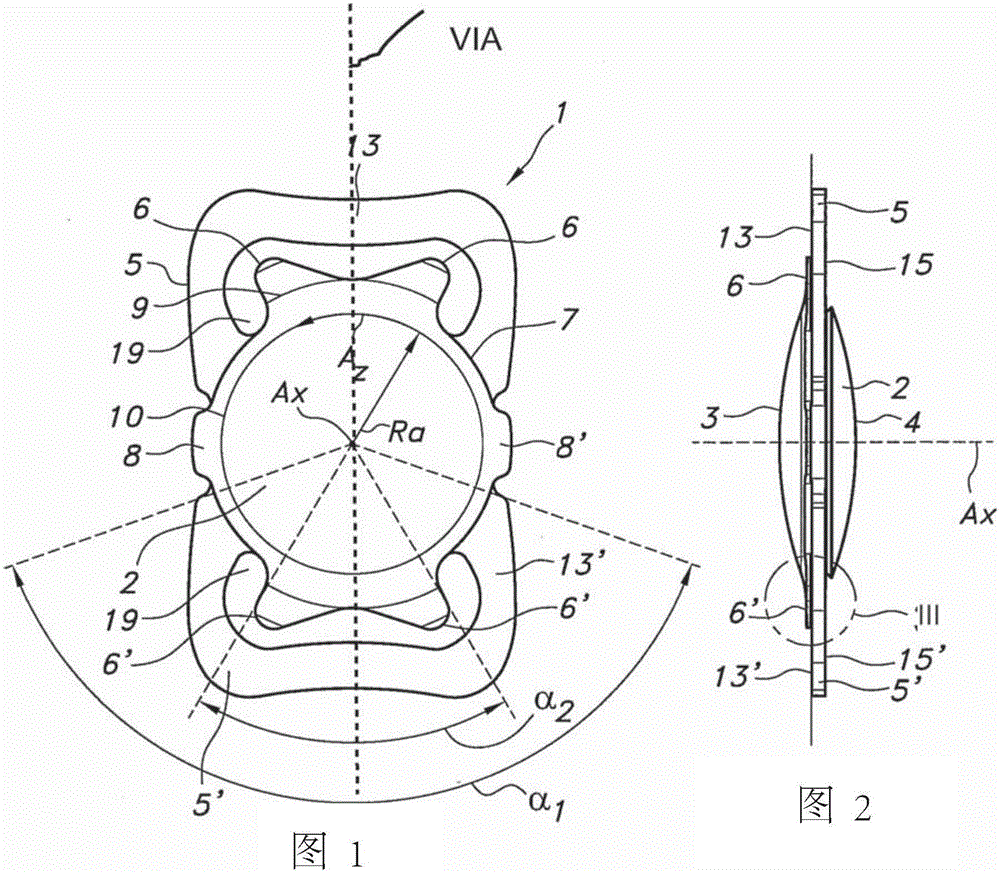

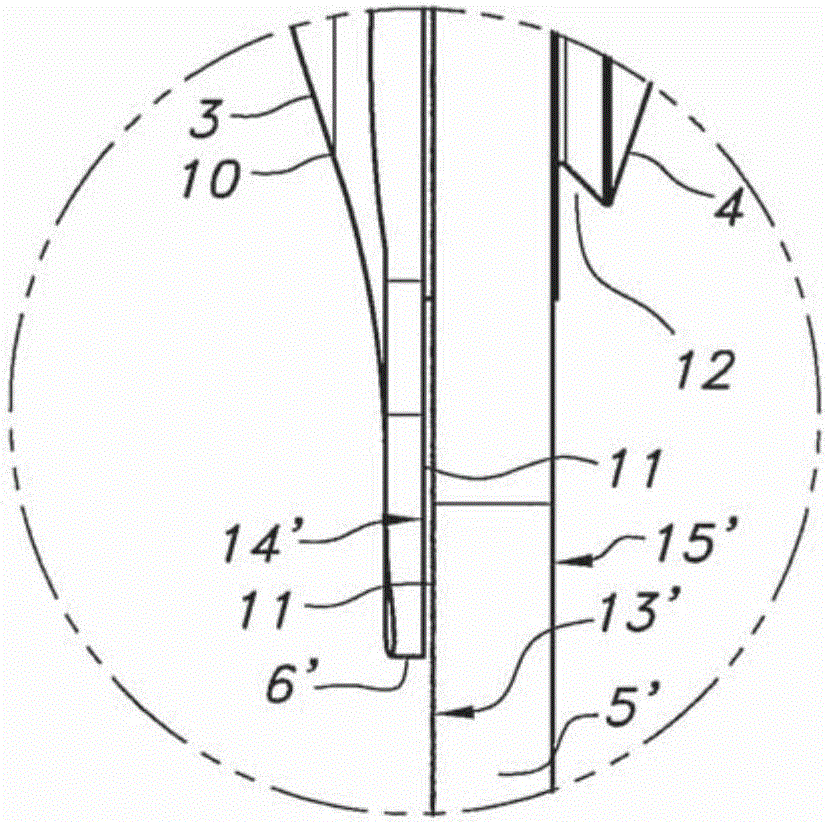

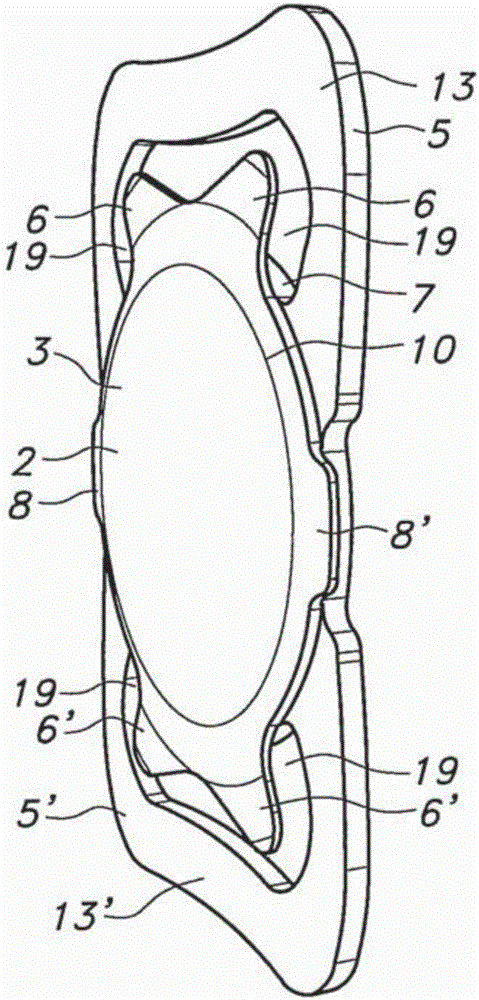

[0158] In this specification, the first relevant part of the eye will be in the Figure 39A , 39B and described in 39C. exist Figure 1-11 , the structure of the intraocular lens (IOL) and its location in the eye will be described ( Figure 9-11 ), and steps for placing such an IOL in the eye. exist Figure 12-35 In, some embodiments of intraocular lens assemblies will be described, which are based on Figure 1-11 The IOL.

[0159] Eye

[0160] exist Figure 39A with 39B In , a cross section through the eyeball 20 is schematically depicted. exist Figure 39A Here, eyeball 20 has cornea 21 , iris 25 , pupil 26 and capsular bag 22 with natural lens 31 . The pouch 22 has a front portion 23 and a rear portion 24 . exist Figure 39B , the eyeball 20 is shown after the natural lens 31 has been removed, leaving an empty capsular bag 22 with an opening 32, which is generally circular or oval. The opening 32 is in the front portion 23 of the pouch 22 . In many cases, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com