Seeding device

A seed and seeding tube technology, applied in the field of sowing machinery, can solve the problems of high labor intensity, inconvenient operation, waste of resources, etc., and achieve the effects of high seeding efficiency, compact structure and uniform seeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

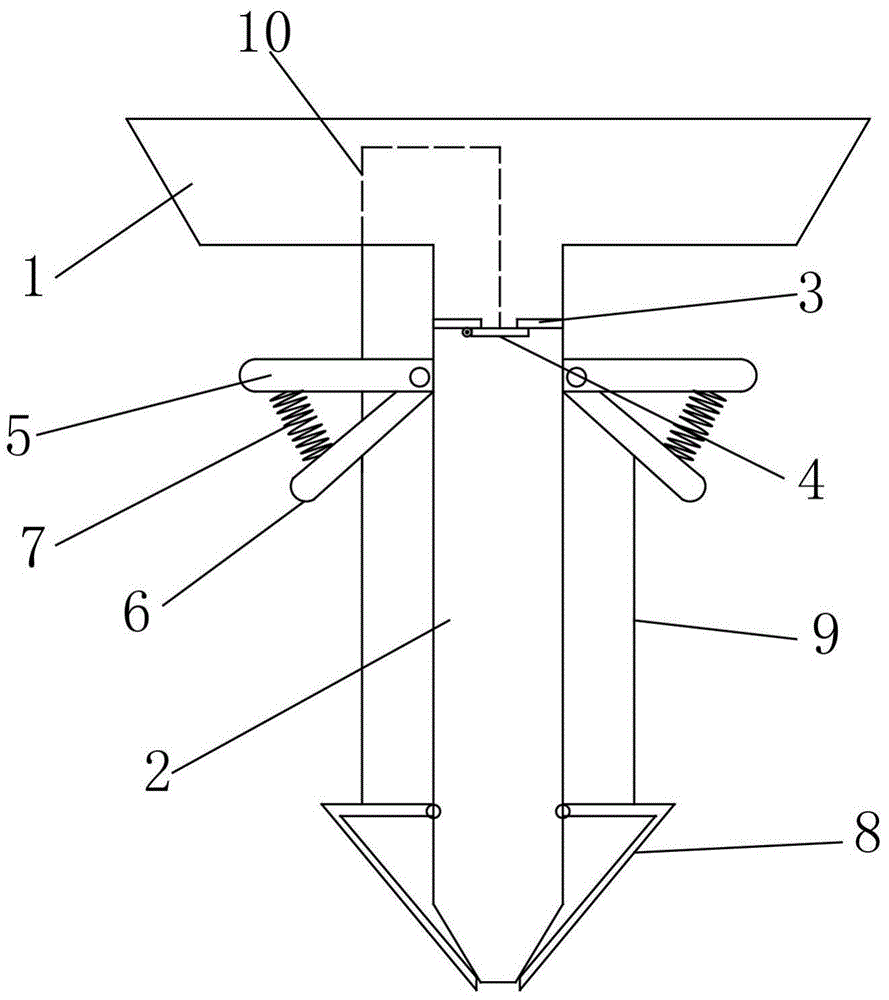

[0012] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in the figure, the sowing device includes a seed trough 1. The lower part of the seed trough 1 is connected with a sowing cylinder 2 with a tapered lower part. There is a hole for the seeds to pass through, and a baffle 4 is arranged directly below the hole, and one side of the baffle 4 is hinged with the lower surface of the partition 3, and a handle 5 is fixed on the upper part of the outer wall of the seeding tube 2, and a handle is hinged below the handle 5 6. A spring 7 is connected between the handle 5 and the handle 6, and a symmetrical "7" shaped soil shifting board 8 is hinged on the lower part of the outer wall of the seeding tube 2, and a transmission rod 9 is connected between the handle 6 and the upper surface of the soil shifting board 8 , The upper surface of the blocking piece 4 is fixedly connected with a linkage line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com