Forming device for thin-wall special-shaped seal rings of engines

A forming device and engine technology, applied in the field of stamping manufacturing, can solve the problems of low yield, high production cost, difficult production of stamping dies, etc., and achieve the effect of high yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

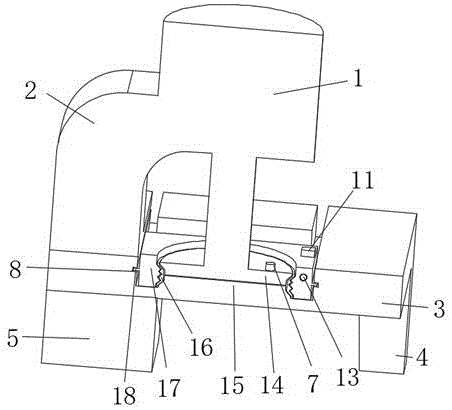

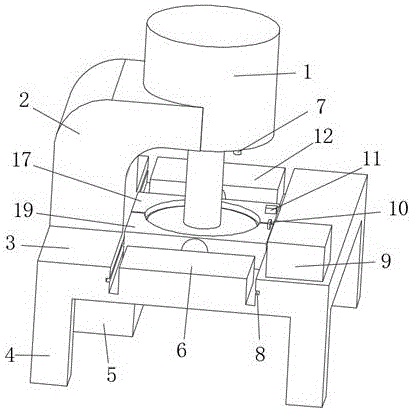

[0023] see figure 1 and figure 2 , the invention relates to a thin-wall special-shaped sealing ring forming device for an engine, which includes a base 3, a support leg 4 is provided at the bottom of the base 3, and a downward first hydraulic cylinder 1 is provided above the base 3 , the left section of the top surface of the base 3 is provided with an upward support arm 2, the support arm 2 is an inverted "L"-shaped cantilever wall structure, and the cylinder body of the first hydraulic cylinder 1 is threadedly fixed to the support arm 2 Free end, the lower end of the cylinder body of the first hydraulic cylinder 1 is provided with a distance sensor 7, the lower end of the hydraulic rod of the first hydraulic cylinder 1 is connected with a circular upper movable mold 14, and the outer edge of the upper movable mold 14 is provided with The cavity of the upper movable mold with the opening downwards, figure 2 The cross-section of the cavity of the upper movable mold is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com