Sizing casing pipe cover for PE-pipe cooling water tank

A technology of cooling water tank and casing cover, applied in the field of sizing casing cover, can solve the problems of nozzle blockage, affecting cooling effect, and poor cooling water inflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

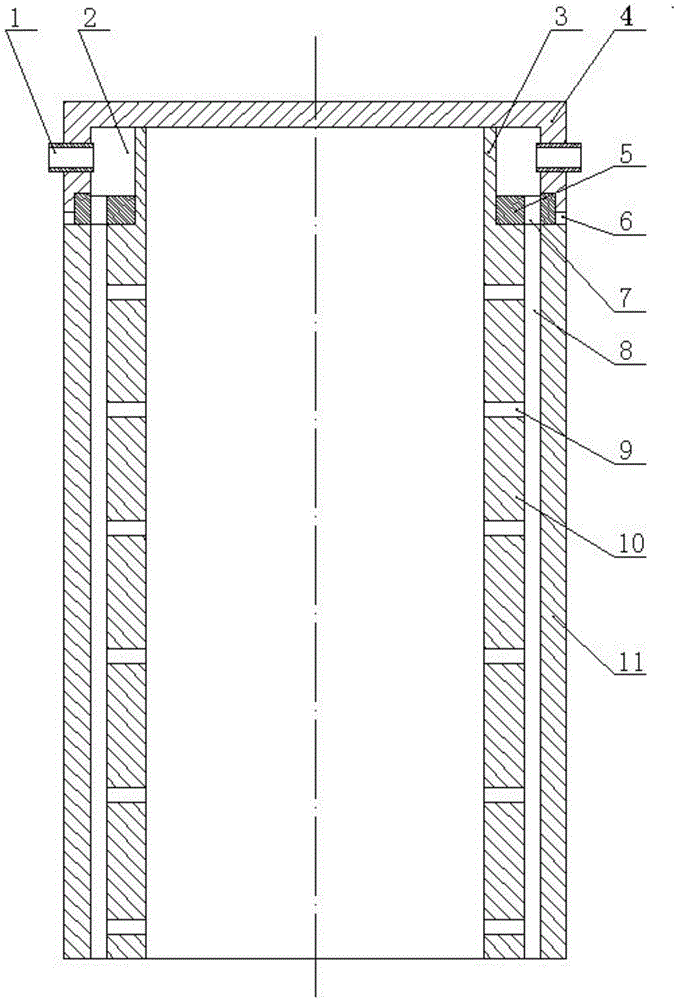

[0012] A sizing sleeve cover for a PE pipe cooling water tank, the sizing sleeve cover 4 is used on the water inlet side of the sizing sleeve, the sizing sleeve includes a sleeve 11 and a sizing tube 10, the sizing A plurality of water outlet holes 9 are evenly distributed in radial intervals on the pipe, and the nozzle 3 of the water inlet side end face of the sizing pipe stretches out from the sleeve, and the nozzle of the water outlet side end face of the sizing pipe is flush with the sleeve barrel mouth.

[0013] Innovation point of the present invention is:

[0014] The end surface of the water inlet side of the sizing pipe is fixed with the sleeve through the fixing ring 5 and there is a coaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com