Ships with integrated ship railings and antenna bases

A technology for antenna pedestals and ships, which is applied to antenna supports/installation devices, ship parts, ship construction, etc., can solve the problems of overall weight, many welding spots, and poor aesthetics, and achieve light weight, welding The effect of fewer points and less welding man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

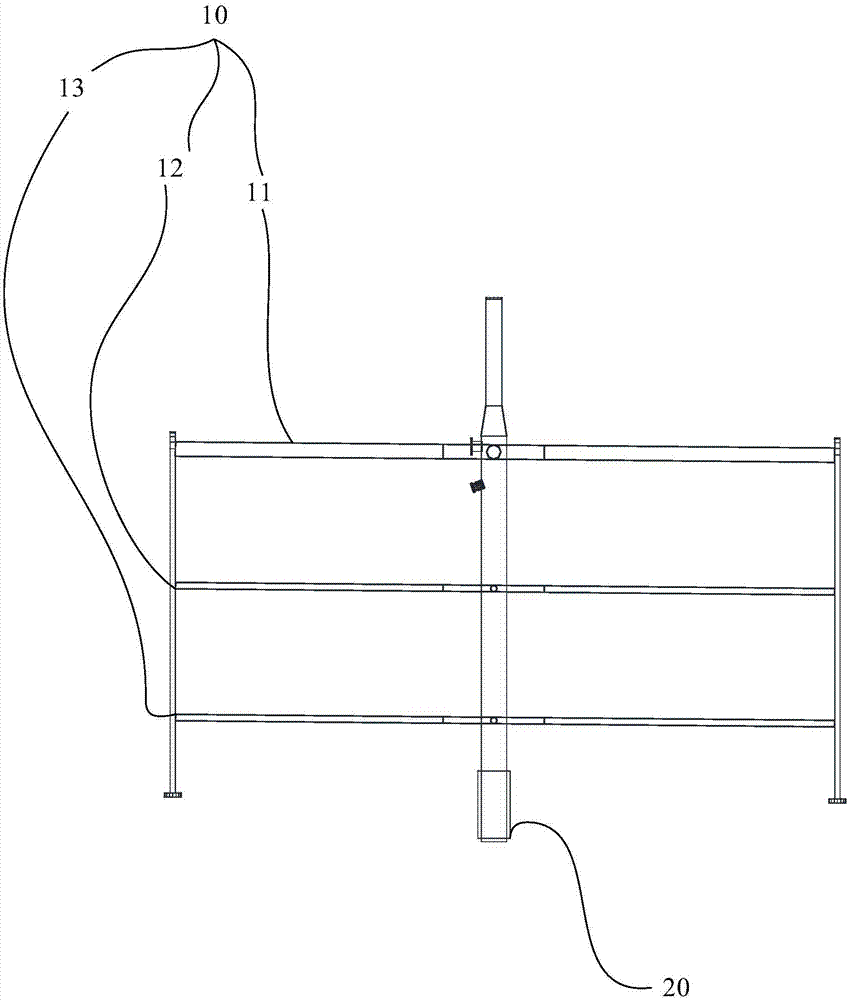

[0040] figure 1 The schematic diagram of the structure of the ship integrated with the ship rail and the antenna base of the present invention is shown.

[0041] Such as figure 1 As shown, a ship integrated with a ship rail and an antenna base includes a ship rail 10 and an antenna base 20. The ship rail 10 includes a horizontal high pole 11, a middle pole 12, and a low pole 13. The poles, the middle poles and the low poles are arranged in parallel and spaced apart in sequence; the antenna base includes a hollow antenna pillar for passing cables, wherein at least two sets of the ship railings are respectively symmetrical They are arranged on both sides of the antenna pillars, and the two sets of ship railings are fixedly connected to the antenna pillars; the bottom of the antenna pillars is fixedly connected to the ship deck. In this embodiment, welding is used for fixed connection.

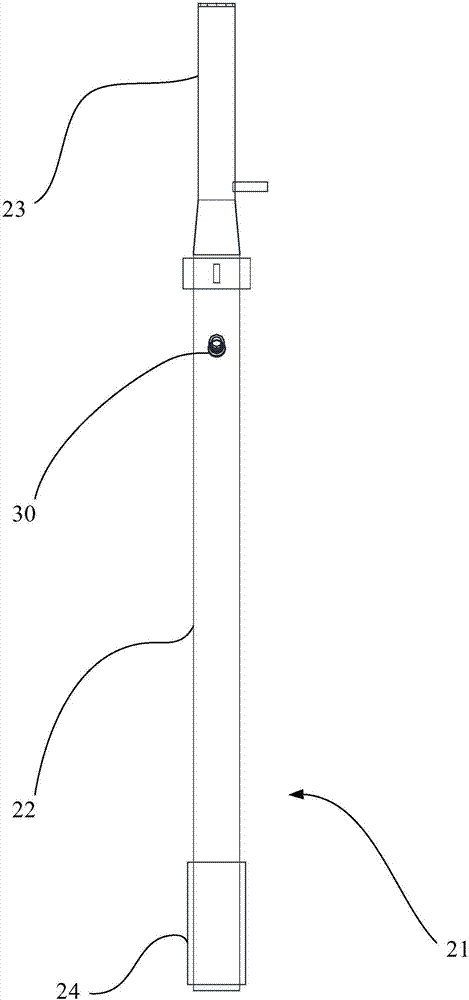

[0042] Such as image 3 As shown, the antenna pillar 21 of the present invention includes a first...

Embodiment 2

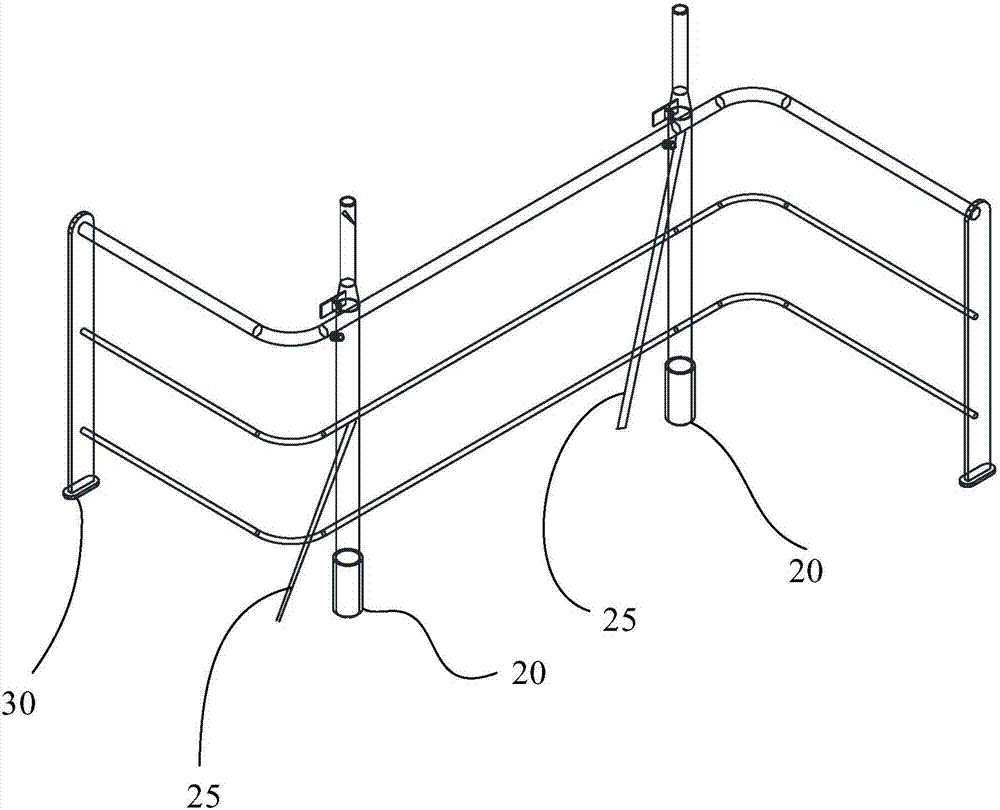

[0044] figure 2 It shows a schematic structural diagram of a ship integrating a ship rail and an antenna base in Embodiment 2 of the present invention.

[0045] In the ship integrated with the ship railing and antenna base in the second embodiment of the present invention, except that the ship rail and the two antenna pillars are connected in an I-shape, the other structures are basically the same as those in the first embodiment of the present invention. the same.

[0046] Such as figure 2 As shown, the ship integrated with the ship railing and the antenna base further includes multiple groups of the ship railings and a plurality of the antenna pillars, and each two groups of the ship railings are vertically arranged on both sides of each antenna pillar. In the second embodiment, three groups of the ship railings and two antenna pillars are adopted, and the ship railings and the two antenna pillars are connected in an I-shaped manner.

[0047] Further, as figure 2 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com