Looping tool and warp knitting machine

A technology of loop forming tools and warp knitting machines, which is applied in warp knitting, textiles, papermaking, knitting, etc., and can solve problems such as lowering the quality of knitted products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

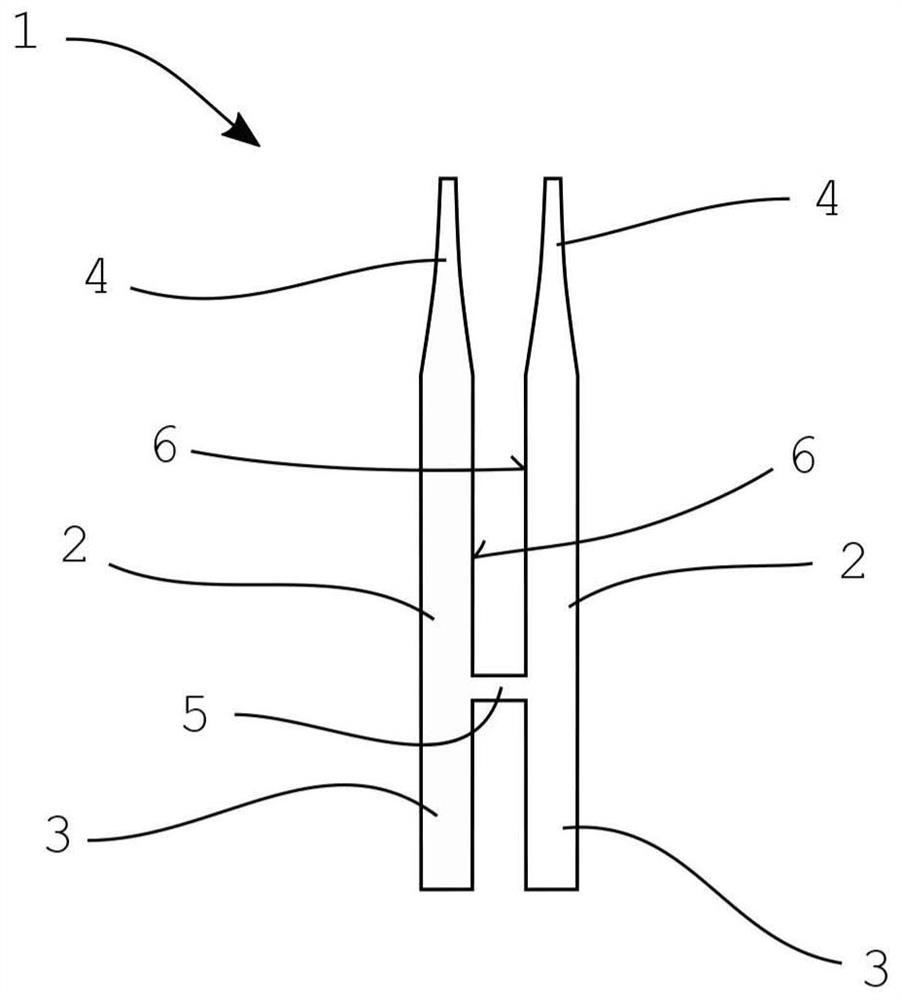

[0042] figure 1 A schematic diagram of a first variant of the loop forming tool 1 of the invention is shown. The loop forming tool 1 has two loop forming elements 2 . Each loop forming element 2 has a stem part 3 and a functional part 4 . The functional part 4 is a needle hook. The connecting element 5 of the loop forming tool 1 connects the two loop forming elements 2 . The loop forming element 2 and the connecting element 5 consist of metal. The connecting element 5 is welded to two facing sides 6 of the loop forming element 2 . The loop forming tool 1 has only two loop forming elements 2 .

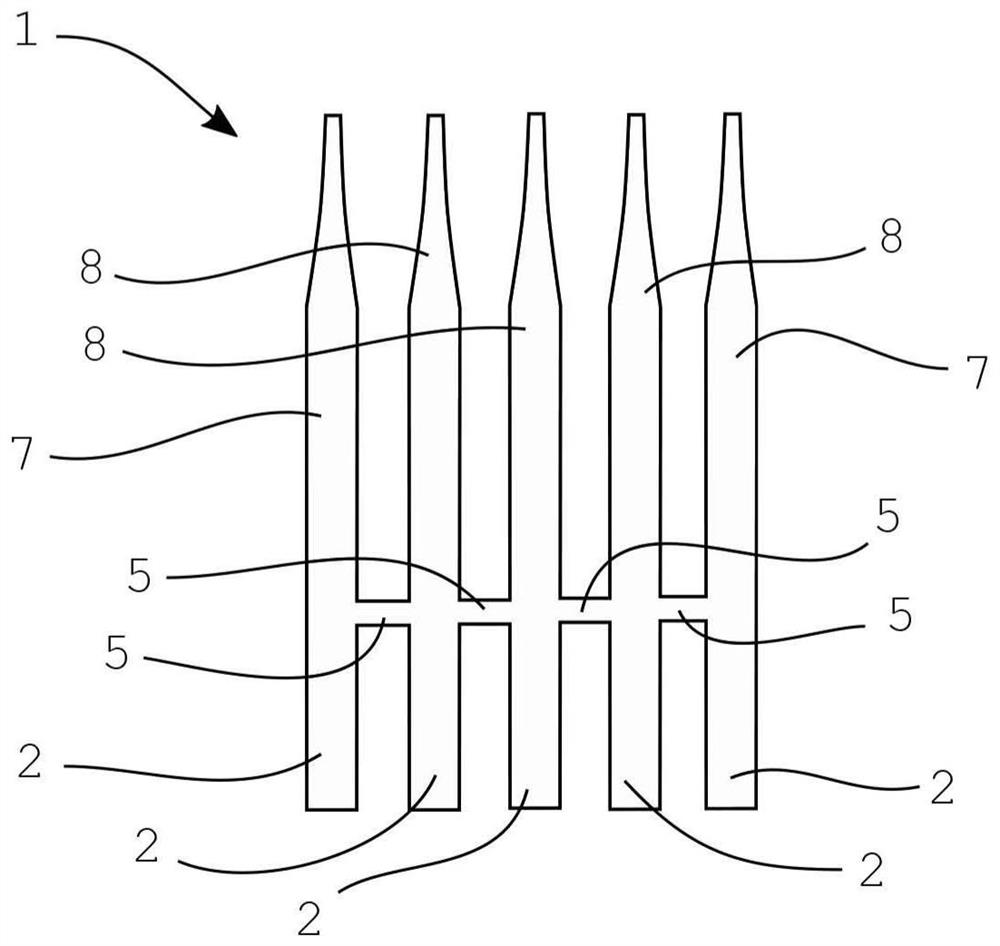

[0043] figure 2 A schematic diagram of a second variant of the loop forming tool 1 of the invention is shown. The loop forming tool 1 has five loop forming elements 2 . Here, it is divided into two outer loop forming parts 7 and three inner loop forming parts 8 . Adjacent loop forming elements 2 are each connected to each other via connecting elements 5 . This stitching tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com