Automatic flow regulating valve for grate cooler

A technology of flow regulating valve and grate cooler, applied in the direction of sliding valve, safety valve, balance valve, etc., can solve the problems of waste material, very thick valve plate, complex structure, etc., achieve simplified structure, light overall weight, and reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

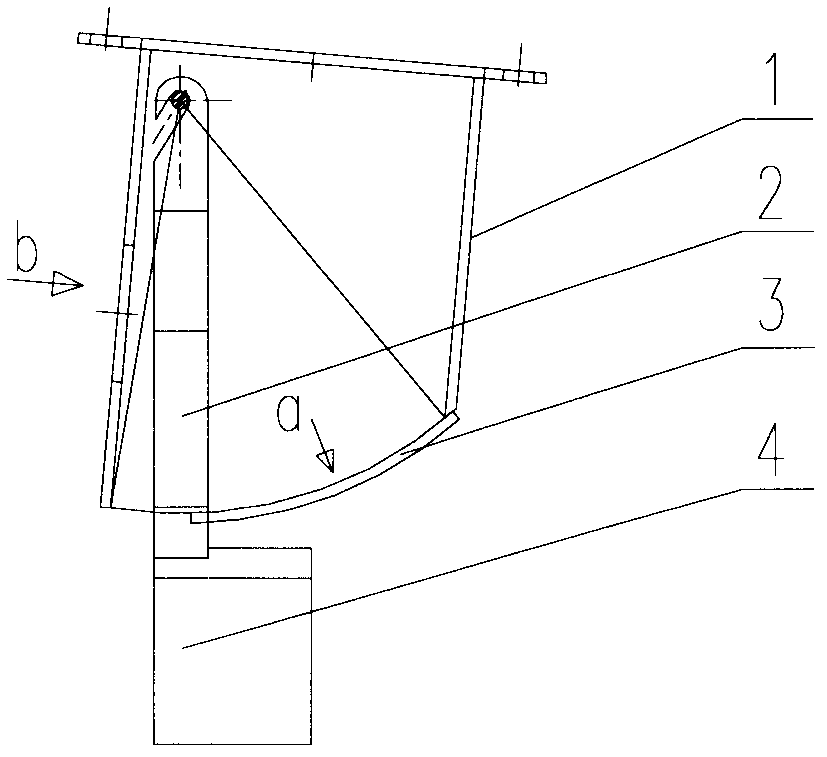

[0008] Referring to the accompanying drawings, its structure includes a valve body 1, a valve plate 2, a bottom air plate 3, and a valve plate counterweight 4, wherein the valve body 1 and the bottom air plate 3 are integrated by welding, and the valve plate 2 and the valve plate counterweight 4 Through welding connection, there is a hanging rod in the valve body, the hanging rod hangs the valve plate 2 on the valve body 1, and there are bolt holes on the top of the valve body 1, and the valve body and the wall plate of the grate cooler are connected and hung by bolts. The upper valve plate can realize the effect of automatically adjusting the air volume.

[0009] The role of valve body 1 is to prevent excess air from entering the valve body. The air can only enter through the fixed ventilation holes on the valve body and the bottom wind plate. The valve plate 2 can change its position with the change of clinker pressure and cooperate with the bottom wind plate to realize adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com