Cleaner hose

A technology for dust collectors and hoses, which is applied to hoses, suction hoses, pipes, etc., and can solve problems such as damage, increased overall weight of hoses, and long-term durability of the electric energy conducting wire 30.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

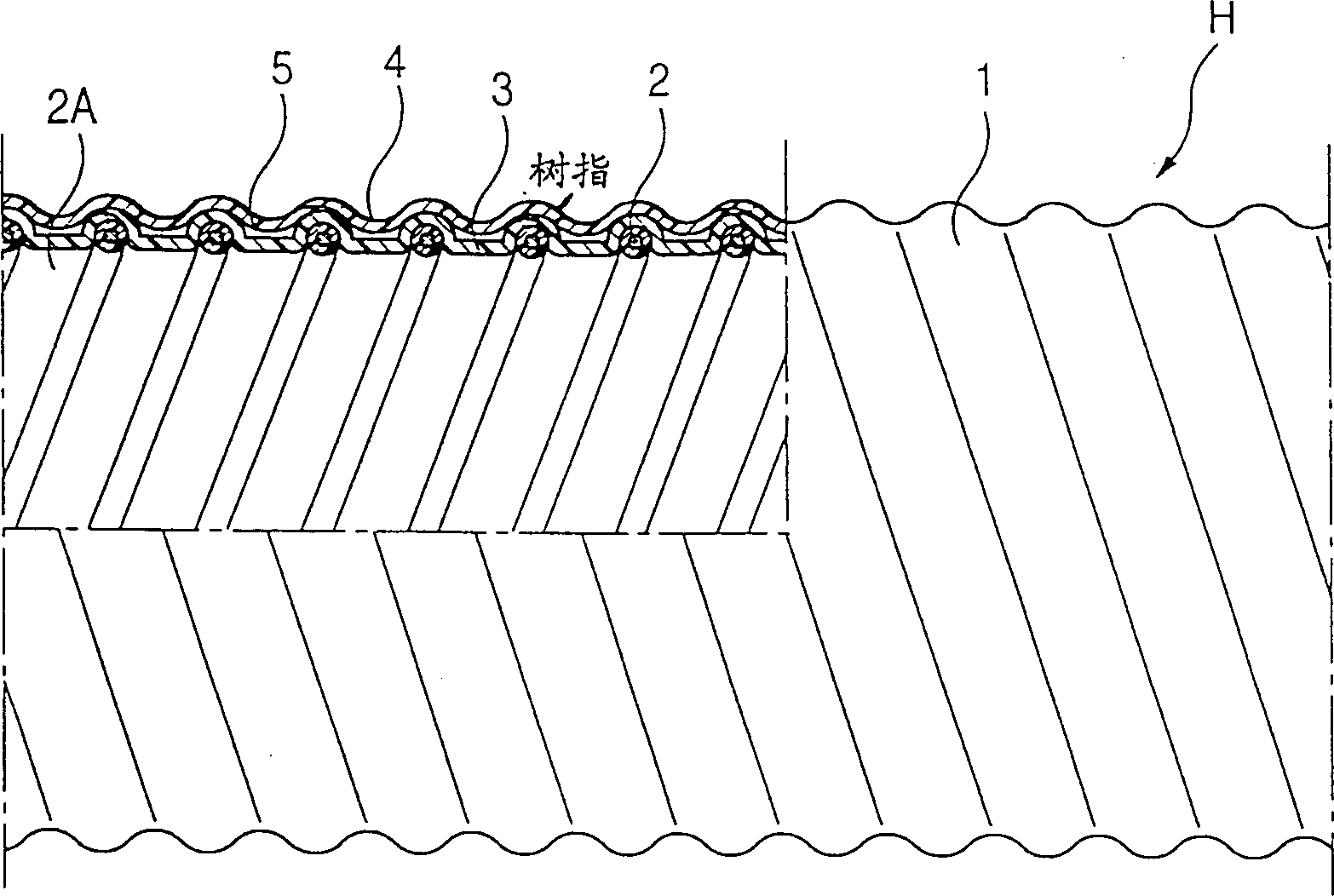

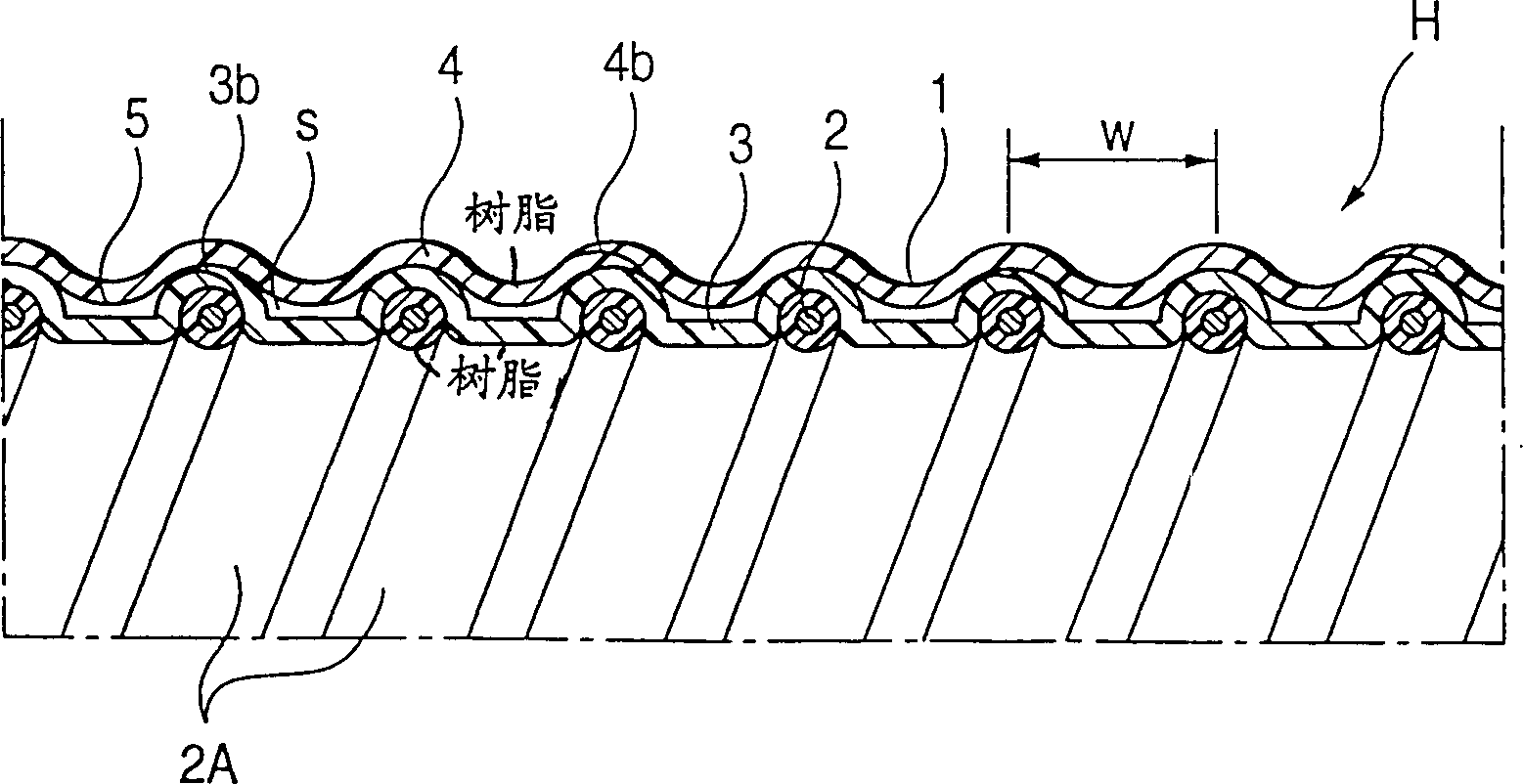

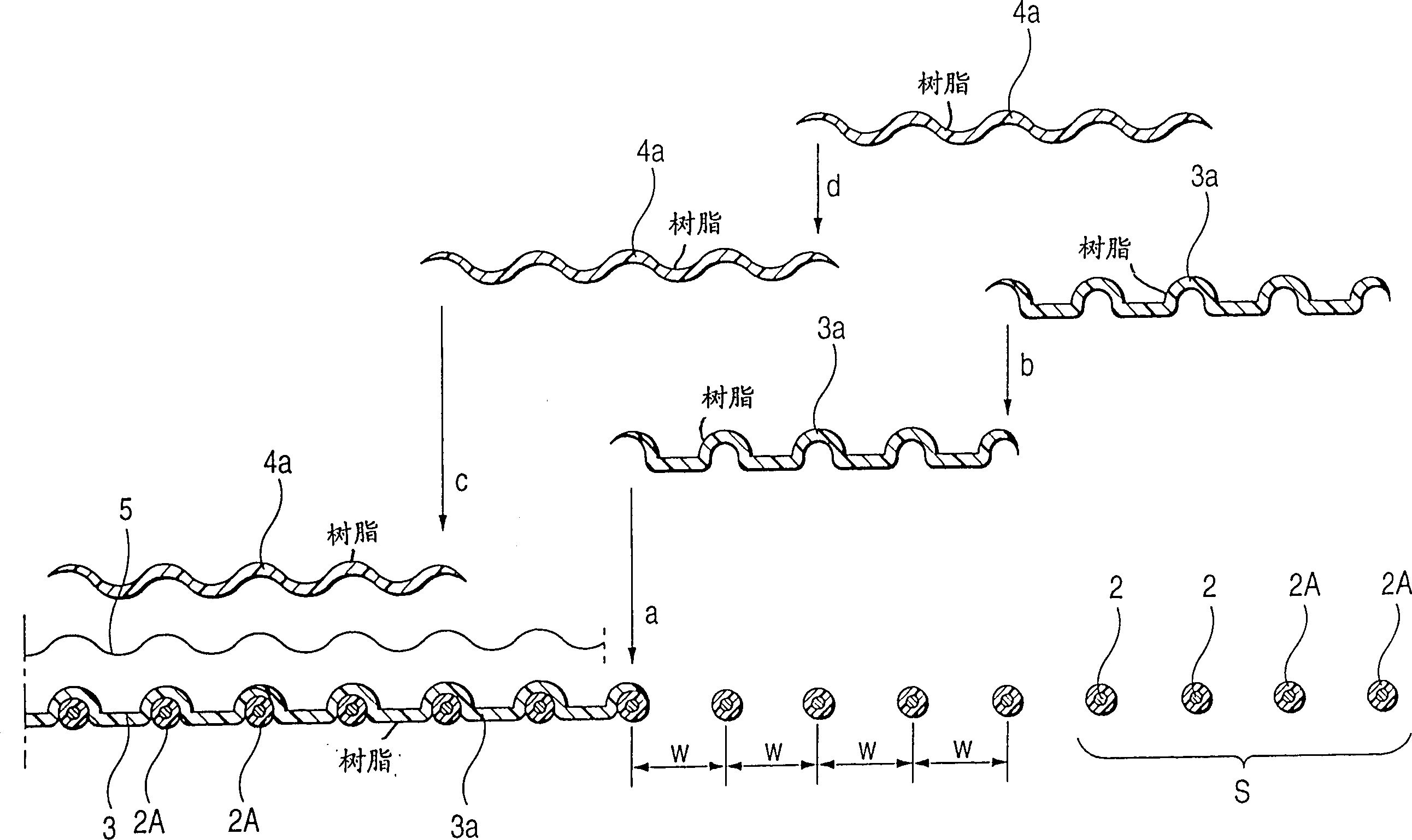

[0022] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0023] In the attached picture, Figure 1 to Figure 4 Shows the first embodiment of the present invention. figure 1 Indicates the partially cut-away state of the hose H. figure 2 Indicates the enlarged cross-sectional shape of the pipe wall portion, image 3 represents in exploded form the materials that make up the hose H, and Figure 4 Indicates the case where connecting pipes are connected to opposite ends. In the hose H, the pipe wall 1 having a helically wound shape is made of a material such as soft polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), or any other synthetic resin material, or rubber with the above-mentioned A mixture of any of the materials constitutes a material. The pipe wall 1 has an inner layer and an outer layer composed of an inner layer 3 and an outer layer 4, and 20 to 30 reinforcing threads 5 of nylon fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com