A special structure unloading device

A special structure, spiral plate technology, applied in the direction of transportation and packaging, conveyors, rotary conveyors, etc., can solve the problems of discontinuous feeding, poor uniformity, easy material jams, etc., to improve feeding efficiency and ensure continuous The effect of sex and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

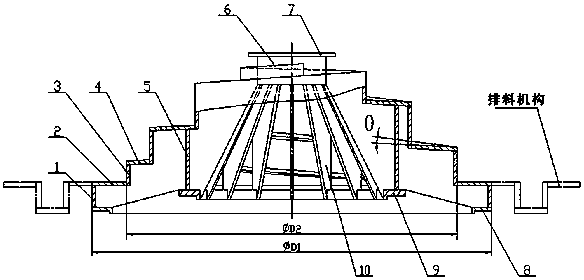

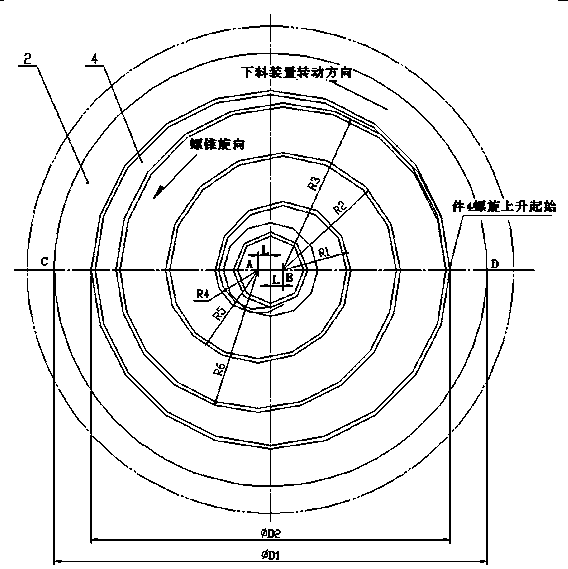

[0018] like figure 1 and figure 2 As shown in the figure, a special structure blanking device includes a first steel plate 8, a second steel plate 9, a steel pipe 6 and a third steel plate 7 arranged in sequence from bottom to top. The top of the first steel plate 8 is connected to the first side plate 1, The upper end of one side plate 1 is the annular plane 2, the upper end of the annular plane 2 is the second side plate 3, the second side plate 3 is connected with the spiral plate 4, and the spiral plate 4 includes the first spiral plate part on both sides of the diameter CD of the annular plane 2 and The second spiral plate part, the first spiral plate part includes three spirals with the same rotation center (both point B), and the rotation center is located on the diameter CD of the annular plane 2, and is far from the center L of the annular plane 2 (the center is to the right) Steel plates, the helical radii of the three spiral steel plates are R1, R2 and R3 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com