Automatic bearing stacking device

A stacking and bearing technology, which is applied in the field of bearing processing, can solve problems such as backward finishing and packaging links, rising processing costs, and product damage, and achieve the effect of not easy bearing damage, regular bearings, and high stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

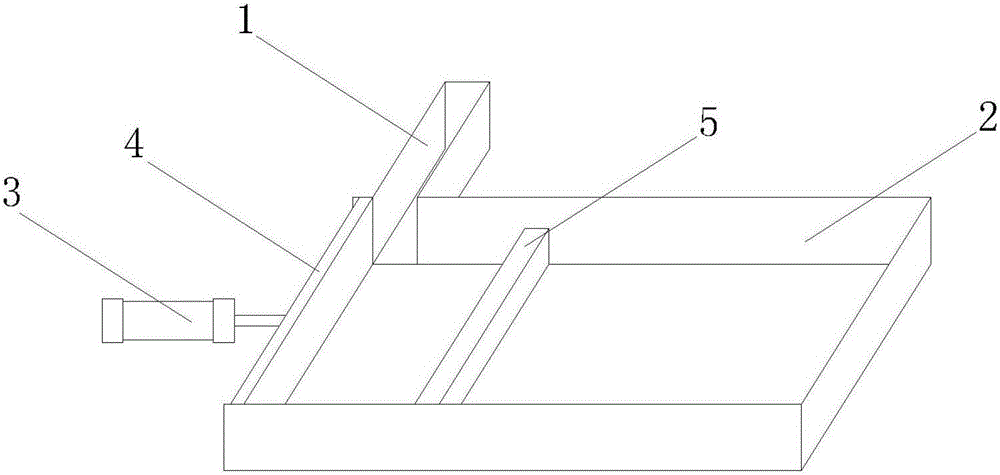

[0008] see figure 1 , the specific embodiment of the present invention adopts the following technical solutions: it includes a guide groove 1, a stacking platform 2, a pneumatic 3, and a baffle plate 4. One end of the guide groove 1 is connected to the outlet of the bearing processing machine, and the other end is connected to one end of the stacking platform 2. The side where the stacking platform 2 is connected to the guide groove 1 is higher, and the other side is lower. There is a pneumatic 3 outside the end where the stacking platform 2 is connected to the guide groove 1. The pneumatic 3 is connected to the baffle 4, and the baffle 4 is set for stacking. In the platform 2, a sliding block 5 is also arranged in the stacking platform 2.

[0009] When the present invention works, the bearings coming out from the outlet of the bearing processing machine are rolled into the stacking table through the guide groove. Because the stacking table is inclined, the bearings will autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com