Full Grouting Sleeves for Prefabricated Building Reinforcement Connections

A technology of building steel bars and grouting sleeves, which is applied in the direction of buildings, building components, building reinforcements, etc., can solve the problems of restricting the application of prefabricated frame structures or technological development, and achieve simple and easy construction process, improve strength, and improve construction efficiency effect

Inactive Publication Date: 2018-06-22

怀化市港翔管桩有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These problems will limit the application or technological development of prefabricated frame structures in my country.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0057] Embodiment 2, in order to improve the bonding strength of the first grouting sleeve and the grouting slurry, the existing protrusion or annular groove 17 is set on the outer surface of the sleeve, refer to Figure 7 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

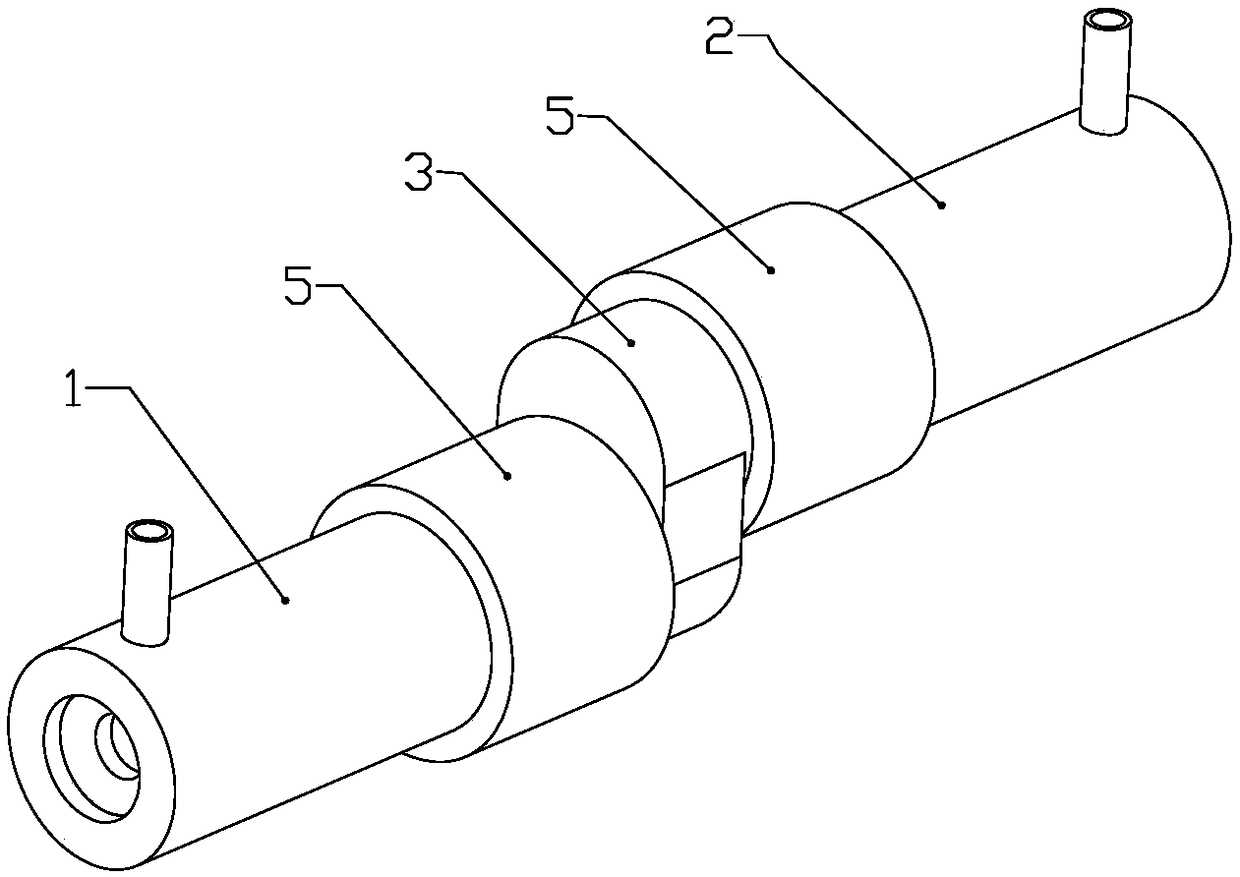

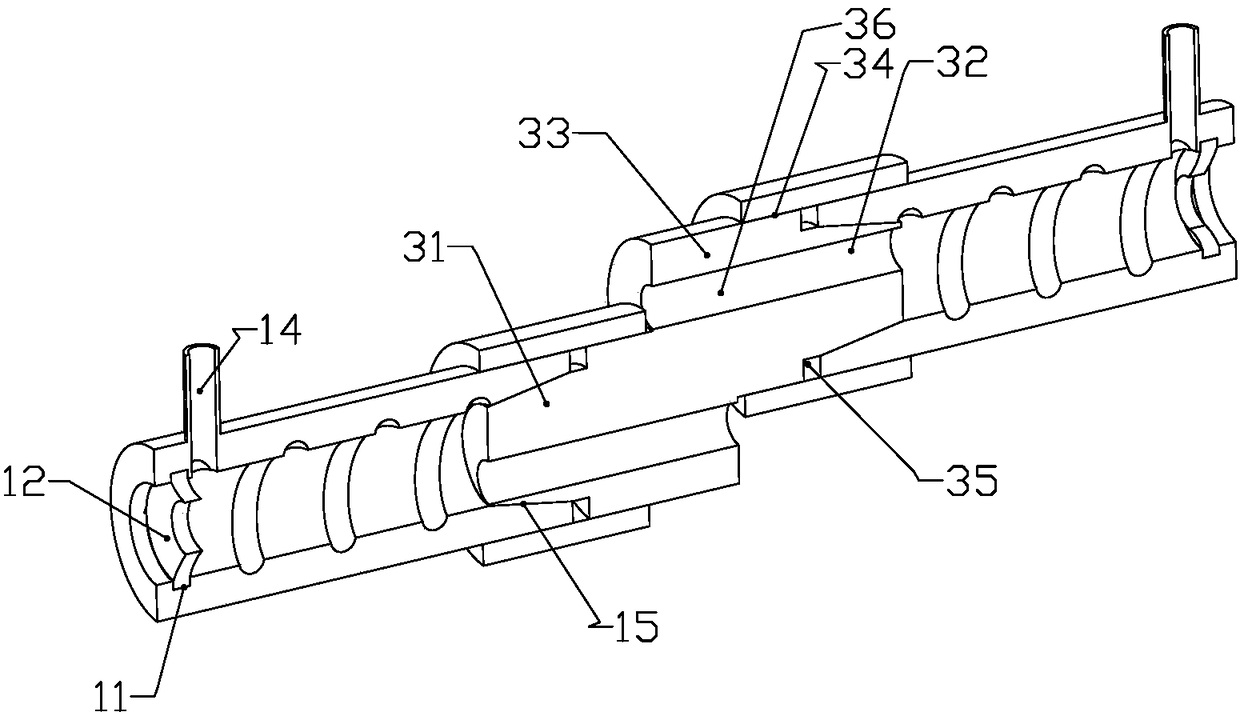

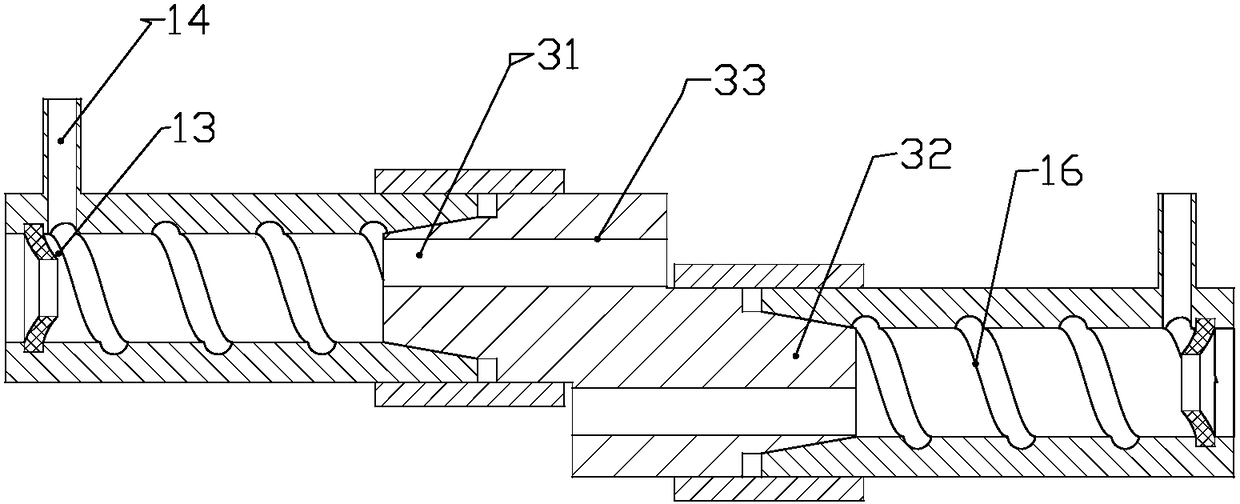

The invention discloses a whole grouting coupler for rebar splicing of a prefabricated building. The whole grouting coupler comprises a first grouting coupler body and a second grouting coupler body and an eccentric joint for splicing the two grouting coupler bodies, wherein the first grouting coupler body and the second grouting coupler body are located on two sides; an annular groove, a first sealing and clamping sheet and a grouting hole are arranged at one end of the first grouting coupler body; an inner cone is arranged at the other end of the first grouting coupler body, and a screw sleeve is arranged on the outer side, corresponding to the first grouting coupler body, of the inner cone section; the eccentric joint comprises a middle disc as well as a first frustum and a second frustum which are located on two sides of the middle disc and arranged in a mutual eccentric manner, and a through grout discharging hole is formed in the center of the first frustum; the second grouting sleeve body adopts the same structure with that of the first grouting sleeve body and is matched with second frustum. An eccentric distance is formed between the two frustums on the middle disc, the problem of deviation of prefabricated members during hoisting and mounting is solved, and the construction process becomes simple and easy to implement.

Description

technical field [0001] The invention relates to the technical field of connection construction of prefabricated concrete components of prefabricated concrete structures, in particular to a sleeve grouting connection structure of transverse steel bars in prefabricated concrete structures. Background technique [0002] At present, prefabricated concrete structures are constructed using industrial technology, and their main structural parts are prefabricated in factories. After arriving at the site, these prefabricated concrete components are installed and connected into a whole. This industrial production method greatly reduces the amount of wet work on the construction site. , significantly increased the construction speed, reduced environmental pollution and material consumption, and has become a new direction for the development of my country's construction industry. The steel bar connection of prefabricated concrete structures is the key to the structural safety. The steel ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): E04C5/18

CPCE04C5/165

Inventor 李敏勇甘立华

Owner 怀化市港翔管桩有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap