Automobile continuously variable transmission with cone friction wheels

A continuously variable transmission, friction wheel technology, applied in the direction of friction transmission, belt/chain/gear, elements with teeth, etc., can solve the problems of high manufacturing cost, complex structure and operation, complex structure of automatic transmission, etc. The effect of low cost and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

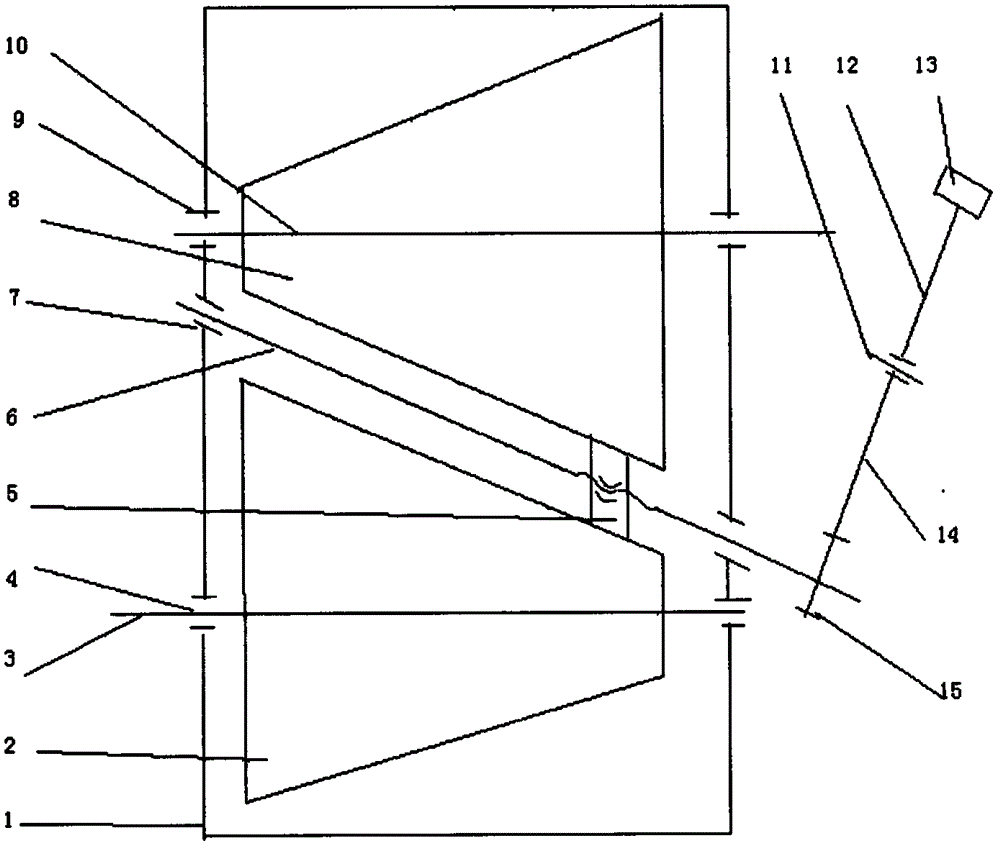

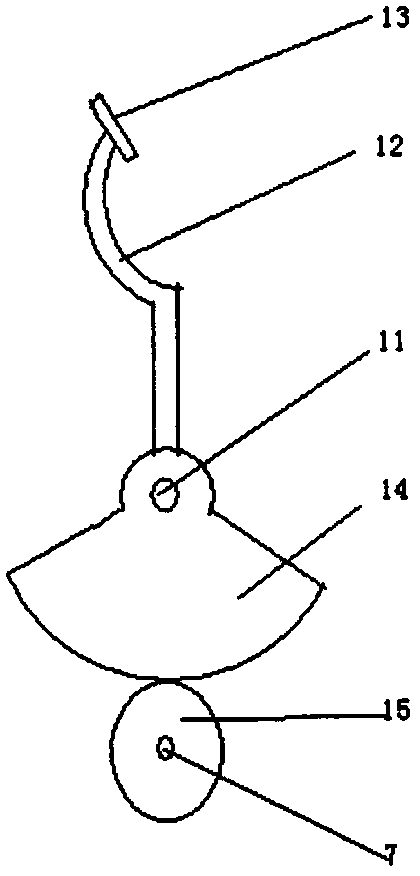

[0015] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached figure 1 , figure 2 The present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0016] The present invention is a kind of tapered surface friction wheel automobile continuously variable transmission, comprising a gearbox body 1, an input shaft 3 arranged in the lower part of the gearbox body 1, a screw shaft 6 arranged in the middle of the gearbox body 1, and arranged in the gearbox body 1 The output shaft 10 in the upper part of the body 1, the input shaft 3 is fixedly connected with the input cone friction wheel 2 with a large left and a small right, and the output shaft 10 is fixed with an output cone friction wheel with a small left and a lar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap