A combined afterburner with fuel injection stability and integration

A technology of afterburner and stabilizer, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc. It can solve the problems of short distance, self-ignition of fuel oil, ablation of stabilizer, etc., and achieves reduced flow resistance loss and simple structure Compactness, the effect of shortening the shortest distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

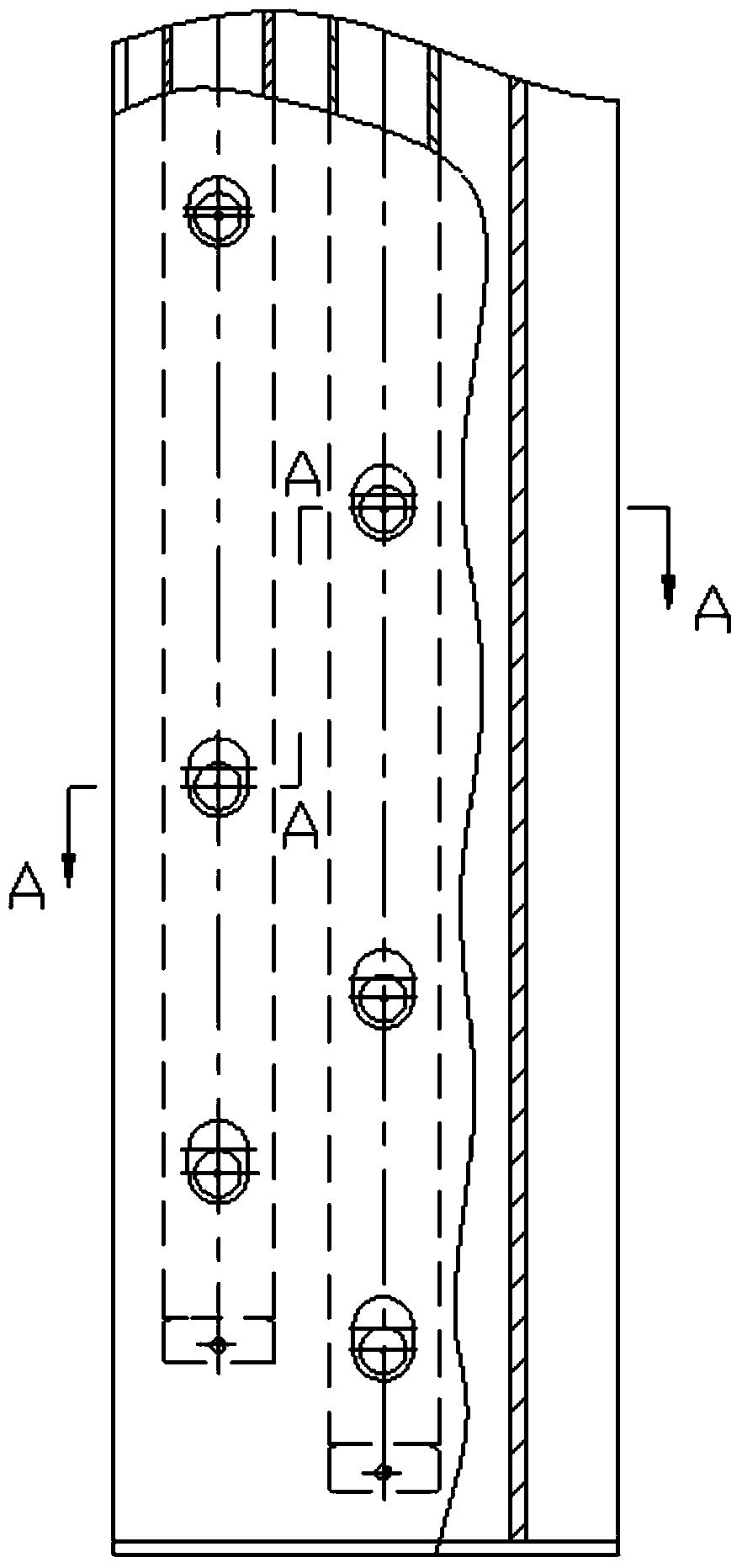

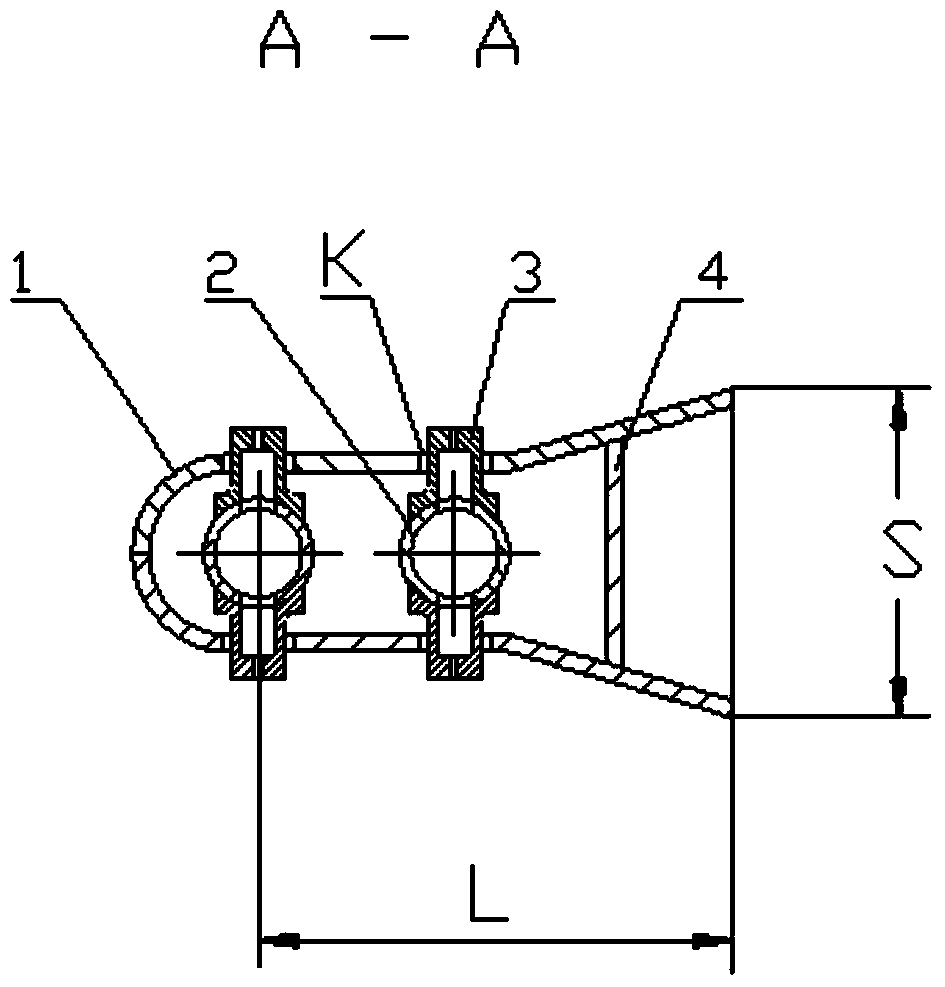

[0015] This embodiment provides a combined afterburner with stable and integrated fuel injection, which is characterized in that the combined afterburner with stable and integrated fuel injection includes a stabilizer side wall 1, a fuel injection rod 2, The fuel injection plug 3 on the fuel injection rod, the tail plate 4;

[0016] Among them: the side wall 1 of the stabilizer and the tail plate 4 form a cavity, the fuel injection rod 2 is placed in the cavity, and the fuel injection plug 3 on the fuel injection rod protrudes through the hole K opened on the side wall.

[0017] The trailing edge of the side wall 1 of the stabilizer is opened by 30° to form a blunt body with a certain width to stabilize the flame.

[0018] A series of fuel injection plugs 3 are welded on the fuel injection rod 2, and a series of oblong holes K are opened on the side wall 1 of the stabilizer. Inside the stabilizer; between a series of oblong holes K and the fuel injection plug 3, there is a ga...

Embodiment 2

[0021] This embodiment provides a combined afterburner with stable and integrated fuel injection, which is characterized in that the combined afterburner with stable and integrated fuel injection includes a stabilizer side wall 1, a fuel injection rod 2, The fuel injection plug 3 on the fuel injection rod, the tail plate 4;

[0022] Among them: the side wall 1 of the stabilizer and the tail plate 4 form a cavity, the fuel injection rod 2 is placed in the cavity, and the fuel injection plug 3 on the fuel injection rod protrudes through the hole K opened on the side wall.

[0023] The trailing edge of the side wall 1 of the stabilizer is opened by 90° to form a blunt body with a certain width to stabilize the flame.

[0024] A series of fuel injection plugs 3 are welded on the fuel injection rod 2, and a series of oblong holes K are opened on the side wall 1 of the stabilizer. Inside the stabilizer; between a series of oblong holes K and the fuel injection plug 3, there is a ga...

Embodiment 3

[0027] This embodiment provides a combined afterburner with stable and integrated fuel injection, which is characterized in that the combined afterburner with stable and integrated fuel injection includes a stabilizer side wall 1, a fuel injection rod 2, The fuel injection plug 3 on the fuel injection rod, the tail plate 4;

[0028] Among them: the side wall 1 of the stabilizer and the tail plate 4 form a cavity, the fuel injection rod 2 is placed in the cavity, and the fuel injection plug 3 on the fuel injection rod protrudes through the hole K opened on the side wall.

[0029] The trailing edge of the side wall 1 of the stabilizer opens 120° to form a blunt body with a certain width to stabilize the flame.

[0030] A series of fuel injection plugs 3 are welded on the fuel injection rod 2, and a series of oblong holes K are opened on the side wall 1 of the stabilizer. Inside the stabilizer; between a series of oblong holes K and the fuel injection plug 3, there is a gap for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com