Semiconductor power element and manufacturing method thereof

A technology of power components and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the drift area and reducing the collapse voltage of semiconductor power components, and achieve the goal of reducing the on-resistance and reducing the distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

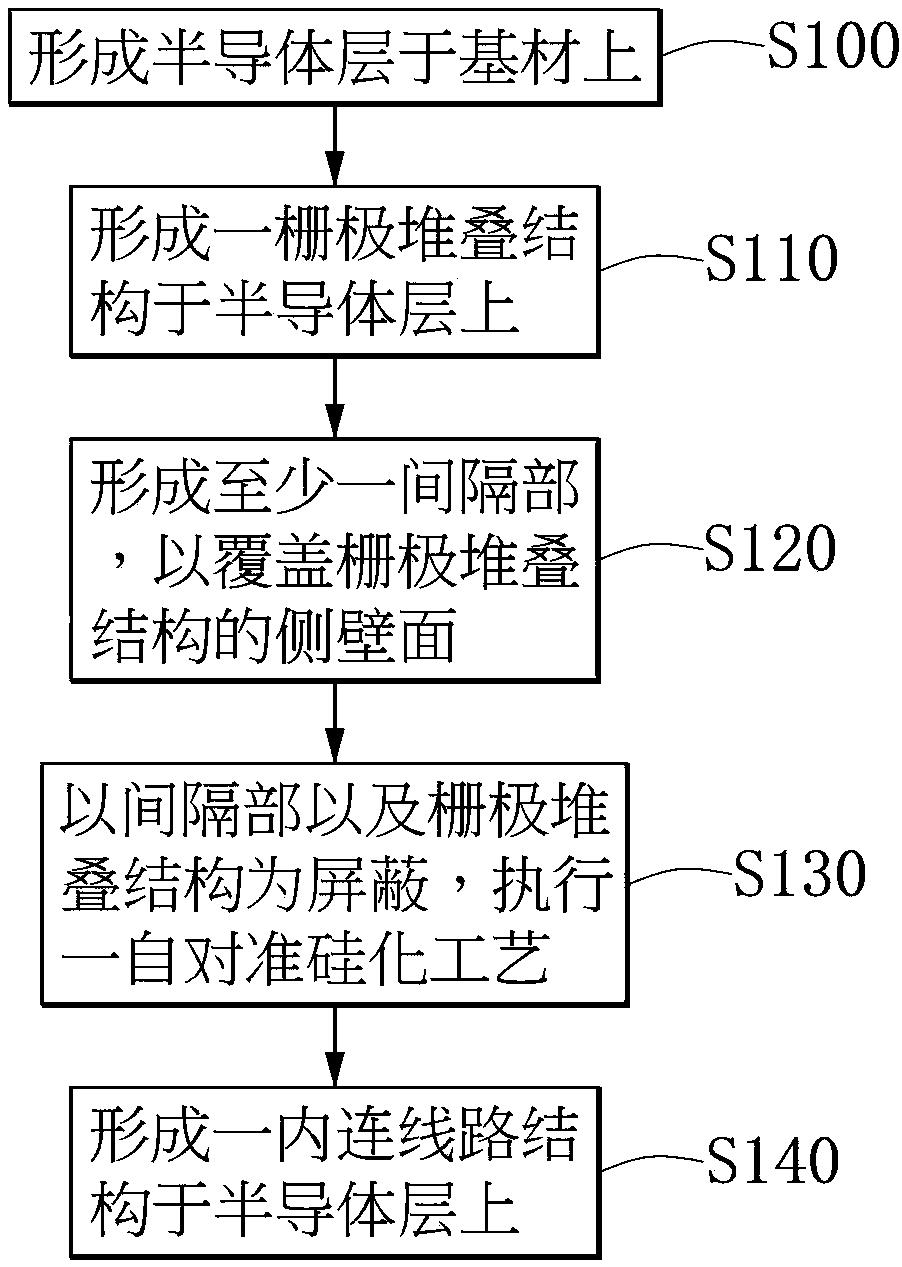

[0037] see figure 1 . figure 1 It is a flowchart of a method for manufacturing a semiconductor power device according to an embodiment of the present invention.

[0038] In step S100, a semiconductor layer is formed on the substrate. Next, in step S110 , a gate stack structure is formed on the semiconductor layer. Subsequently, in step S120 , at least one spacer is formed to cover the sidewall surface of the gate stack structure. In step S130, a self-aligned silicidation process is performed using the spacers and the gate stack structure as a shield. Afterwards, a silicide layer contacting the source region is formed, and in step S140 , an interconnection circuit structure is formed on the semiconductor layer.

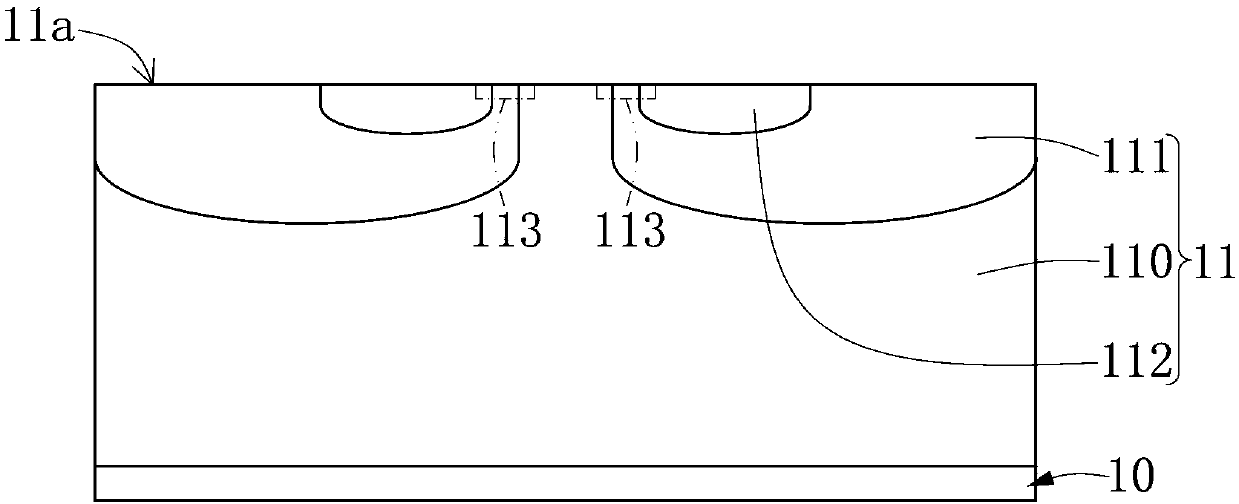

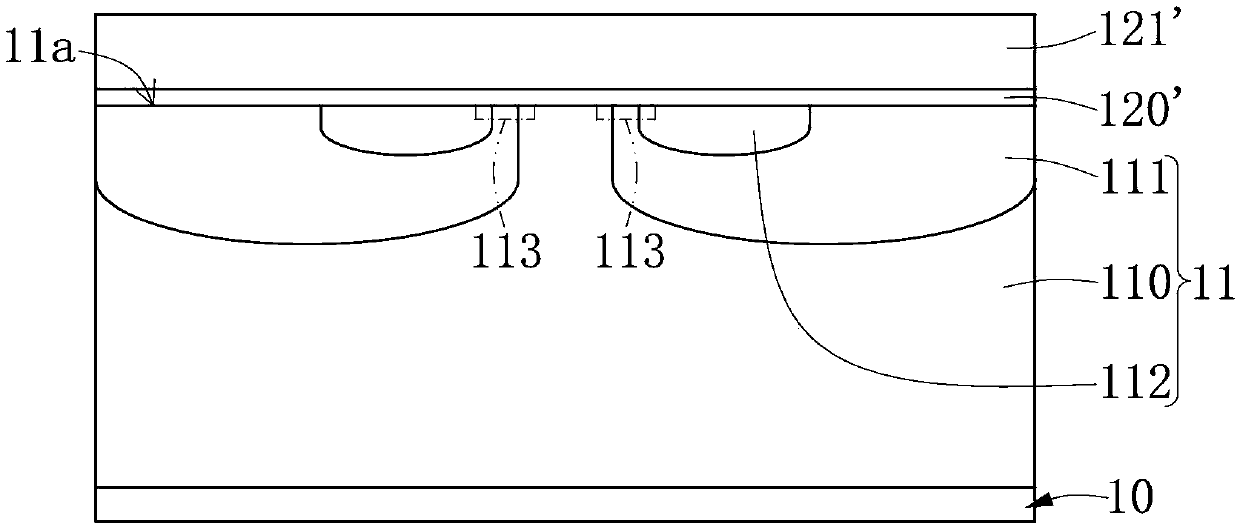

[0039] As mentioned above, in this embodiment, before the step of forming the interconnection wiring structure, the spacer covering the sidewall surface of the gate stack structure is firstly formed, and the salicide process is performed. The specific steps in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com