High-accuracy testing method of oil content of polyester staple fibers

A technology of polyester staple fiber and test method, applied in the field of transfer extraction method, can solve the problems of large friction coefficient, poor hygroscopicity and electrical conductivity, affecting spinning quality and efficiency, etc., and achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

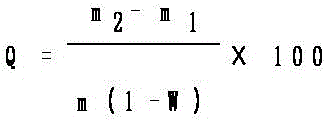

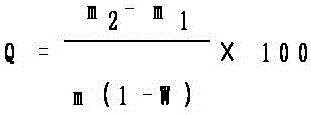

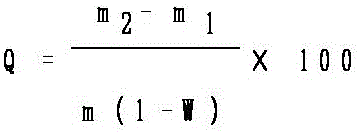

Image

Examples

Embodiment 1

[0050] (1) Weigh 2 samples at random, each sample is 4-5g, accurate to 0.01g;

[0051] (2) Put the weighing bottle in an oven and bake it to a constant weight at 105°C (the difference between the two weighings before and after the weighing is controlled within 0.05%), move it into a desiccator, cool to room temperature, weigh and record the weighing bottle drying before extraction Dry mass m 1 , Accurate to 0.1mg;

[0052] (3) Wrap the sample into a cylindrical shape with qualitative filter paper, and place it in the extraction cylinder of the Soxhlet extractor (ensure that the height of the sample cylinder does not exceed the highest point of the siphon), connect the distillation flask, and inject 100-130ml into the extraction cylinder Ether, install the condenser;

[0053] (4) Set the temperature of the constant temperature water bath to 50-60℃, install the Soxhlet extractor containing the sample on the constant temperature water bath, heat the constant temperature water bath to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com