Production method of fur fabric with color piece

A technology of plush fabric and velvet fabric, which is applied in the field of clothing fabrics, can solve the problems of poor cleaning resistance and easy deformation, and achieve a fashionable and realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

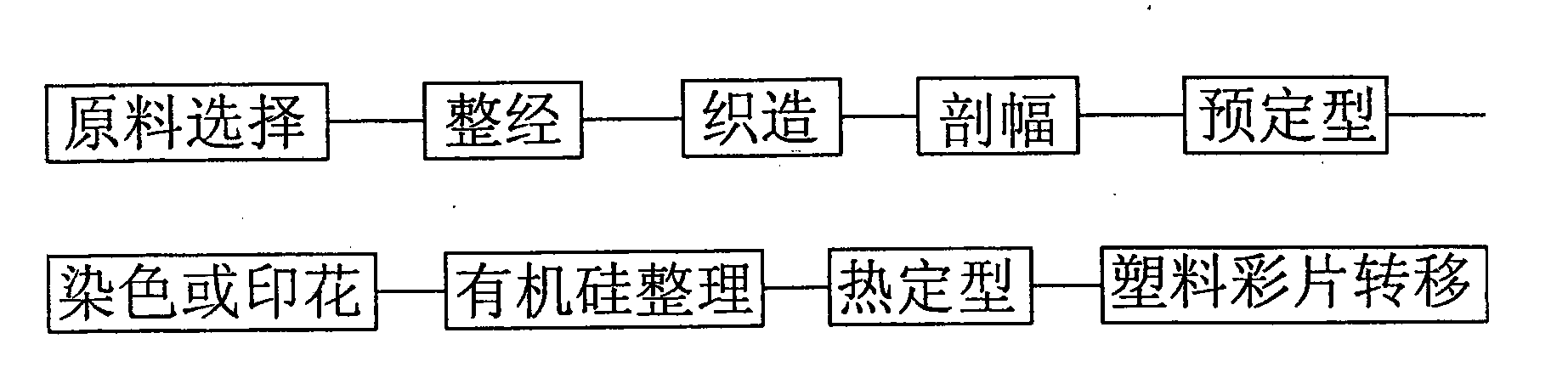

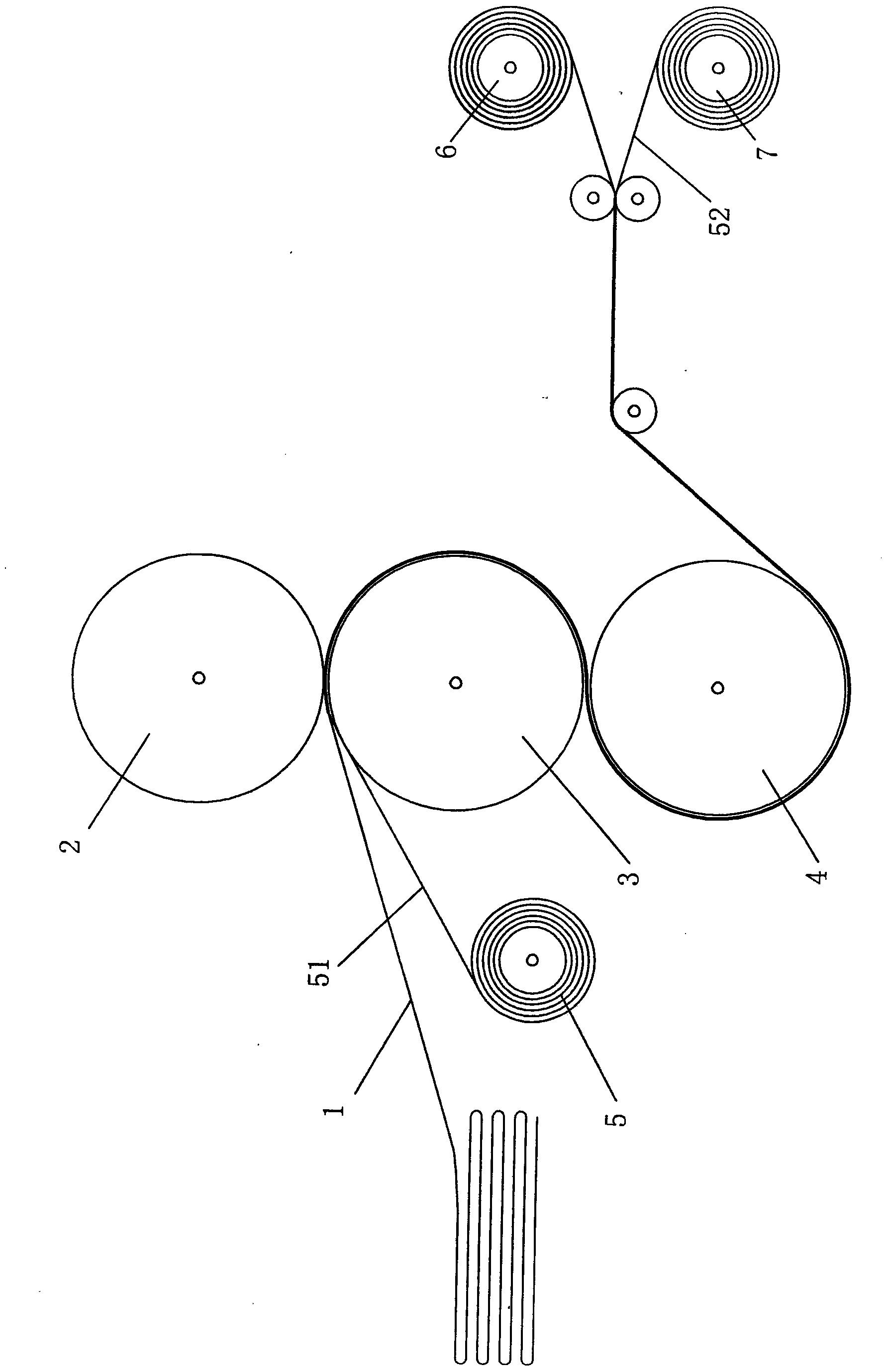

[0022] See figure 1 and figure 2 , the steps included in the preparation method of the color piece fur fabric of the present invention are as follows: raw material selection, warping, weaving, cutting, presetting, dyeing, organosilicon finishing, heat setting and plastic color piece transfer, the applicant is as follows Describe each step in detail.

[0023] Raw material selection: choose 68D / 24F full-dull polyester filament as the bottom texture yarn, choose 75D / 36F full-dull polyester filament as the surface texture yarn, wherein: the mass % ratio of the bottom texture yarn in the fabric is 20% , and the mass % ratio that face texture silk accounts for in the fabric is 80%, obtains raw material;

[0024] Warping: the raw materials obtained by the aforementioned raw material selection steps, i.e. the bottom texture silk and the surface texture silk, are put into real-time by GE209 type computer produced by Changzhou Eighth Textile Machinery Co., Ltd., Jiangsu Province, Chi...

Embodiment 2

[0033] Raw material selection: choose 75D / 36F full-dull polyester filament as the bottom texture yarn, choose 150D / 72F full-dull polyester filament as the surface texture yarn, wherein: the mass % ratio of the bottom texture yarn in the fabric is 35% , and the mass % ratio that face texture silk accounts for in the fabric is 65%, obtains raw material;

[0034] Warping: the speed of the warping machine is controlled at 500rpm, and during the warping process, the strength of the bottom texture yarn and the surface texture yarn is controlled to 8g, and the warped bottom texture yarn and surface texture yarn that are put into weaving are obtained;

[0035] Weaving: obtain a double-layer gray fabric with a pile height of 8 mm, a grammage of 300 g / ㎡, and a width of 1.5 m;

[0036] Cutting: the speed of the cutting knife belt of the cashmere cutting machine is 720rpm to obtain a single-layer white gray cloth;

[0037] Pre-setting: the pre-setting temperature is 180°C, and the cloth ...

Embodiment 3

[0043] Raw material selection: choose 75D / 36F full-dull polyester filament as the bottom texture yarn, choose 150D / 72F full-dull polyester filament as the surface texture yarn, wherein: the mass % ratio of the bottom texture yarn in the fabric is 20% , and the mass % ratio that face texture silk accounts for in the fabric is 80%, obtains raw material;

[0044] Warping: the speed of the warping machine is controlled to be 575rpm, and during the warping process, the strength of the bottom texture yarn and the surface texture yarn is controlled to 6g to obtain the warped bottom texture yarn and surface texture yarn that are put into weaving;

[0045] Weaving: obtain a double-layer gray fabric with a pile height of 9mm, a grammage of 350g / ㎡, and a width of 2.4m;

[0046] Cutting: the speed of the cutting knife belt of the cashmere cutting machine is 680rpm, and a single-layer white gray cloth is obtained;

[0047] Pre-setting: the pre-setting temperature is 185°C, and the cloth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com