Contact lens restoring instrument

A technology for contact lenses and glasses room, applied in the directions of glasses/protective glasses, glasses/goggles, instruments, etc., which can solve the problems of not fundamentally solving the problem of waterproofing, liquid spillage, and difficulty in storing contact lenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

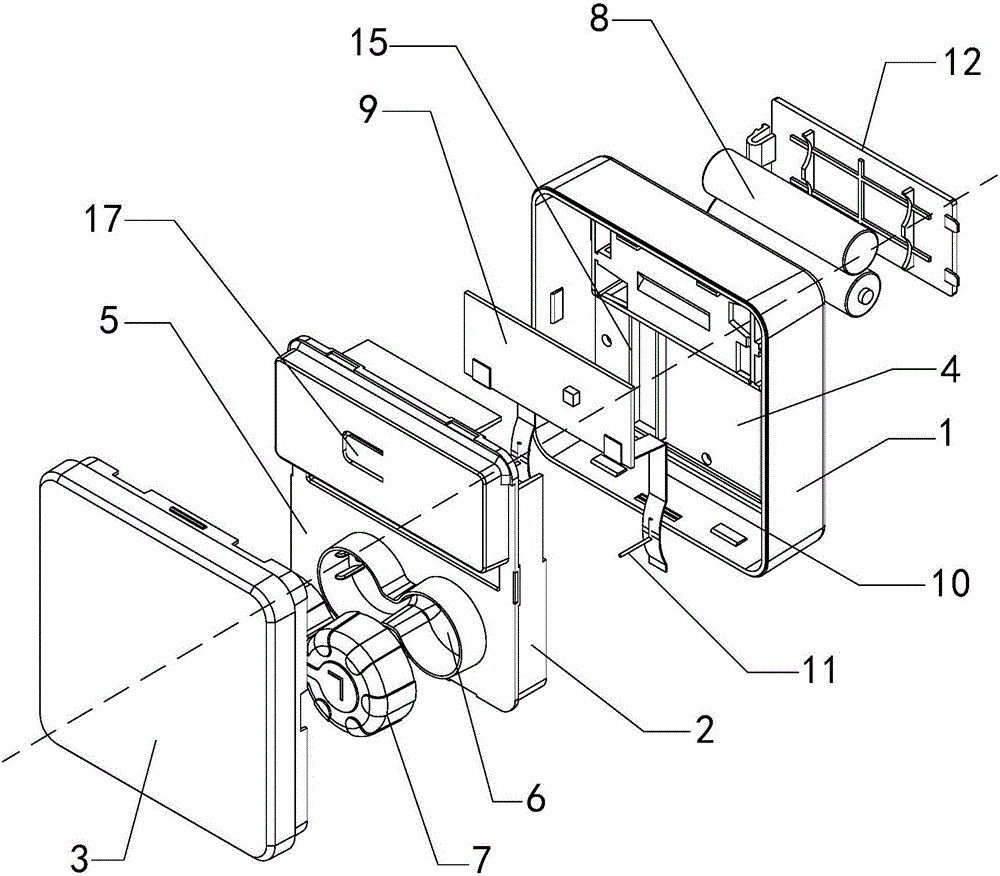

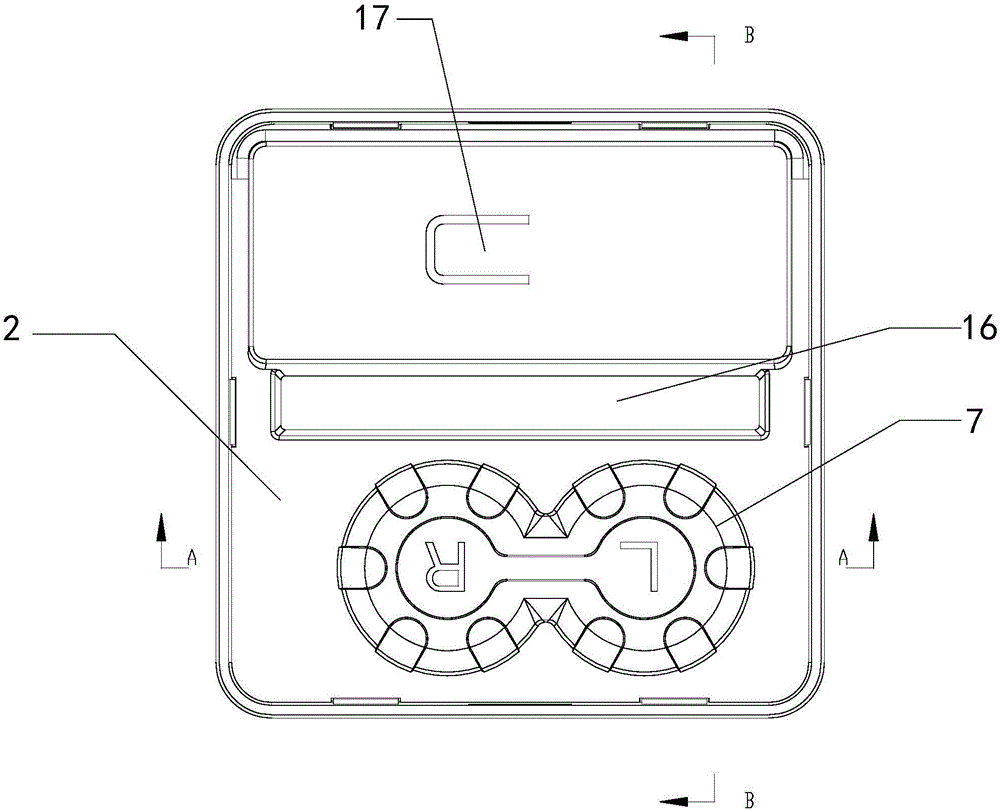

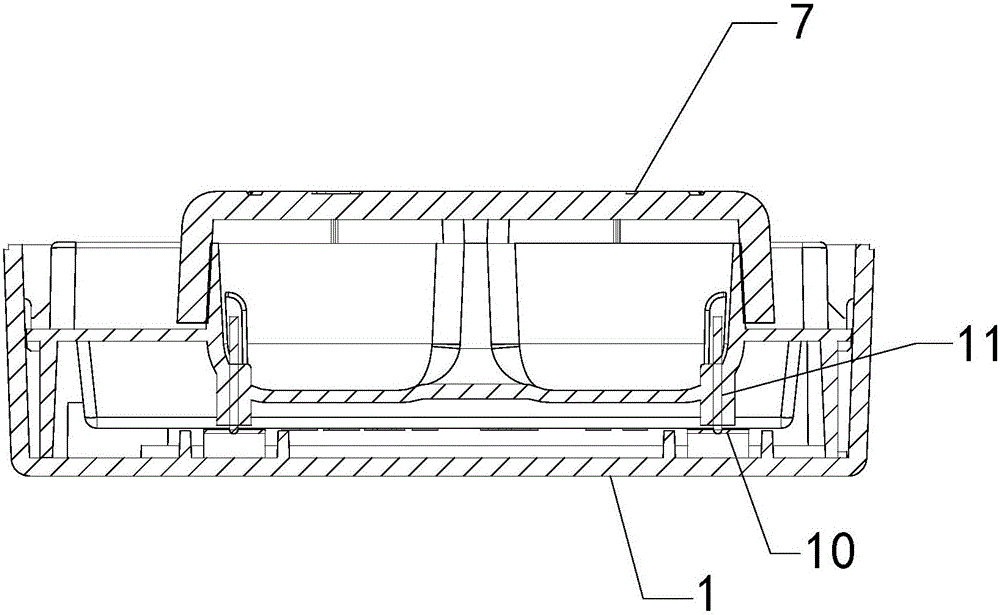

[0032] Such as Figure 1 to Figure 4 As shown, a contact lens reduction instrument according to a preferred embodiment of the present invention includes a base 1, a middle base 2, a cover 3 and a cleaning mechanism. The middle base 2 is closed above the base 1 and forms an electronic component with the base 1. Room 4, the cover body 3 is closed above the middle seat 2 and forms a glasses room 5 with the middle seat 2; the top surface of the middle seat 2 is provided with two accommodating grooves 6 for placing contact lenses and communicating with each other, accommodating A sealing cover 7 is fastened on the groove 6; the cleaning mechanism includes a power supply 8, a circuit board 9, a conductive sheet 10 and an electrode 11; the circuit board 9 is arranged in the electronic component room 4 and is electrically connected to the power supply 8; two, all arranged in the electronic component chamber 4, and one end thereof is electrically connected with the circuit board 9; the...

Embodiment 2

[0039] Such as Figure 1 to Figure 4 As shown, in a contact lens reduction instrument according to a preferred embodiment of the present invention, the electrodes 11 are usually arranged symmetrically at opposite ends of the two accommodating grooves 6, and stoppers are arranged on both sides of the electrodes on the accommodating grooves 6. Flow ridges to avoid impact on the electrode surface when the cleaning agent flows. The shape of the electrodes 11 can be columnar or sheet. Compared with the columnar electrodes, the production cost of the sheet-shaped electrodes is higher, and the contact area with the accommodating tank is larger. Therefore, in the present invention, the columnar electrodes are taken as an example for further description.

[0040] In order to prevent the cleaning agent from leaking due to poor sealing between the electrode and the holding tank, the outer surface of the electrode 11 is provided with a rough surface, which can be achieved in a variety of ...

Embodiment 3

[0043] Such as Figure 1 to Figure 4 As shown, in a contact lens reducing instrument according to a preferred embodiment of the present invention, the position on the conductive sheet 10 that is in contact with the bottom of the electrode 11 is set as an elastic conductive part 14, and the implementation of the elastic conductive part can be various, for example , one end is bent upwards to contact the bottom of the electrode, and the elastic force of the bending position is used to realize the mutual pressure contact connection between the electrode and the conductive sheet (not shown in the figure); one end can also be tilted upward to contact the bottom of the electrode Contact, using the elastic recovery force of the deformation of the conductive sheet to realize the mutual pressing contact connection between the electrode and the conductive sheet (not shown in the drawings); Figure 4 As shown, the middle part can also be arched into an arc-shaped sheet, and the elastic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com