Self-propelled track conveyor line

A technology for conveying lines and conveying vehicles, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as large energy consumption, wear of trays and belts, and impact on production progress, so as to reduce losses and save resource allocation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

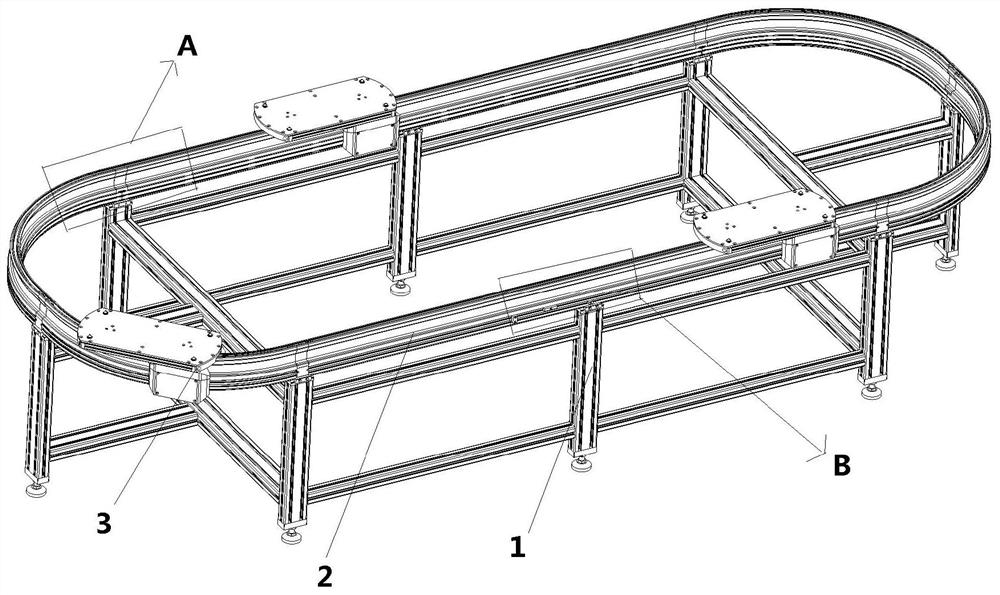

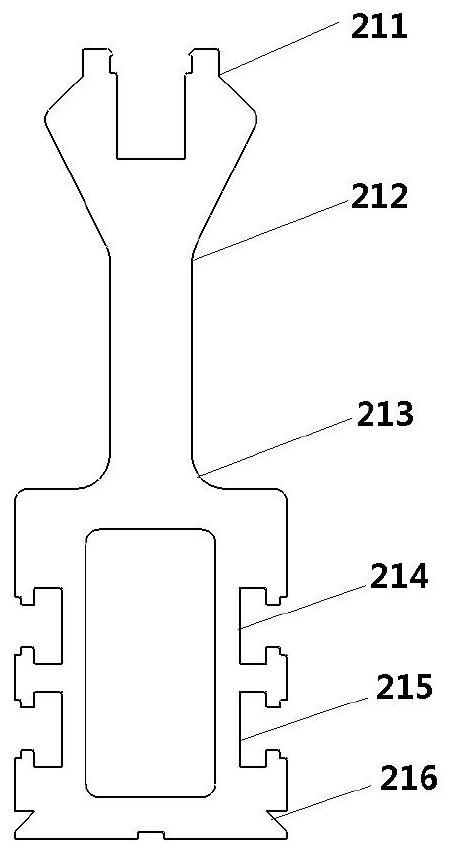

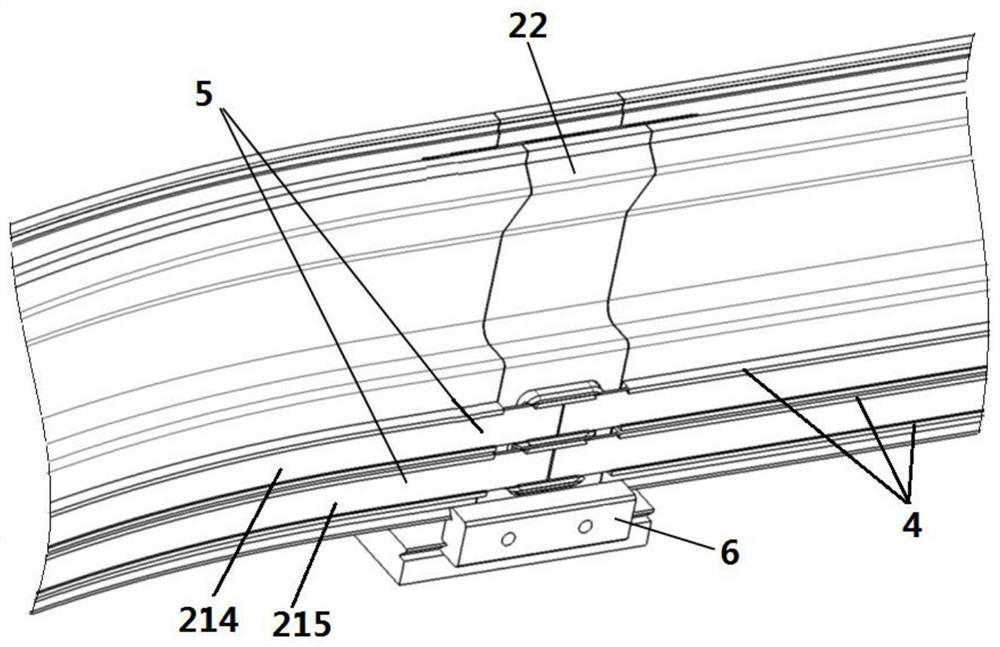

[0041] refer to Figure 1-3 : A kind of self-propelled track conveying line, comprising support 1, conveying track 2 and conveying vehicle 3, described conveying track 2 is arranged on the described support 1, and the both sides of described conveying track 2 are set up along conveying direction from top to bottom There are a first passage 211, a second passage 212, a third passage 213, a fourth passage 214 and a fifth passage 215, the fourth passage 214 and the fifth passage 215 are fixedly installed with an insulating card slot 4, and the insulating card The conductive strip 5 is clamped in the groove 4, and the bottom ends of both sides of the conveying track 2 are provided with a clamping groove passage 216 .

[0042] refer to image 3 , Figure 5 , Image 6 : the two conveying tracks 2 are connected by a guide rail transition block 22, the structure of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com