Rotating shaft welding fixture of drawer seat drive mechanism of low-voltage switch board

A welding fixture and driving mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the inconvenience of clamping gears, the inability to guarantee the angle and position accuracy of the four gears, and the low clamping efficiency, etc. problems, to achieve the effect of convenient and fast clamping, avoid the cumbersome lock of screw connection, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

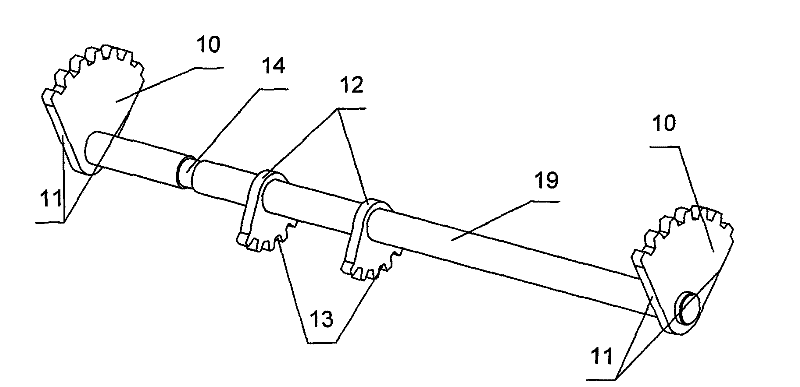

[0013] Such as figure 1 , Four sector gears are welded on the shaft 19 of the drawer seat drive mechanism of the low-voltage power distribution cabinet. Among them, two large sector gears 10 are welded on both ends of the shaft 19, and two small sector gears are welded in the middle of the shaft 19 respectively. 12. A ring groove 14 is provided on the rotating shaft 19 between one of the large sector gears 10 and the small sector gear 12.

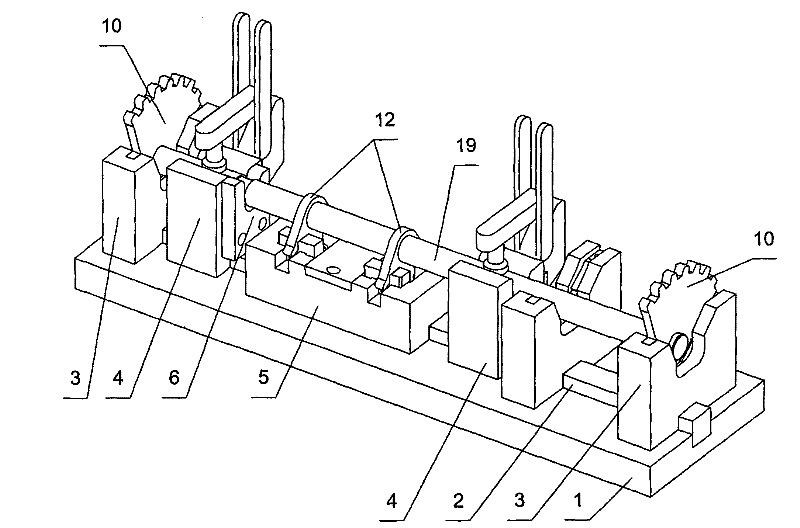

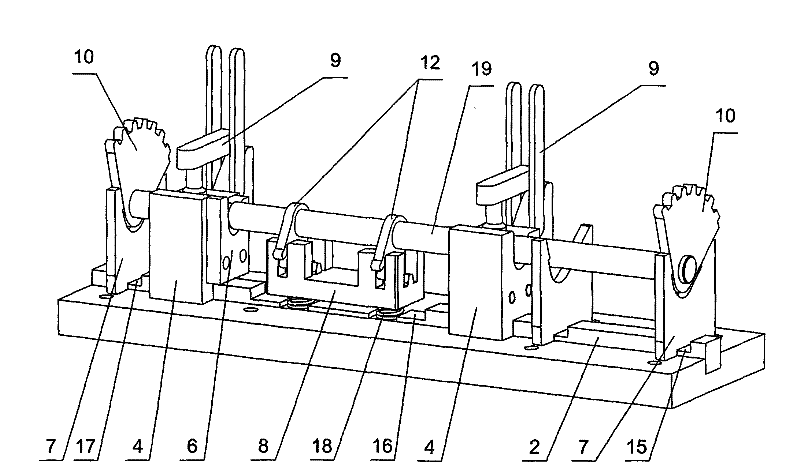

[0014] Such as figure 2 , 3 As shown, a positioning device is fixed on the bottom plate 1 of the welding fixture, and the positioning device includes a positioning square bar 2 and various positioning blocks. Fix the positioning square bar 2 in the square groove on the bottom plate 1. At the two ends and the middle of the positioning square bar 2, there are three positioning notches 15, 16, 17 in different positions, and the guide is fixed at the position of the positioning notch 16. Block 5, the guide block 5 corresponds to the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com