Hard disk device

A hard disk device, hard disk technology, applied in the direction of instruments, record carrier structural parts, record information storage, etc., can solve the problems of high production cost, complicated hard disk device manufacturing process, etc., and achieve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

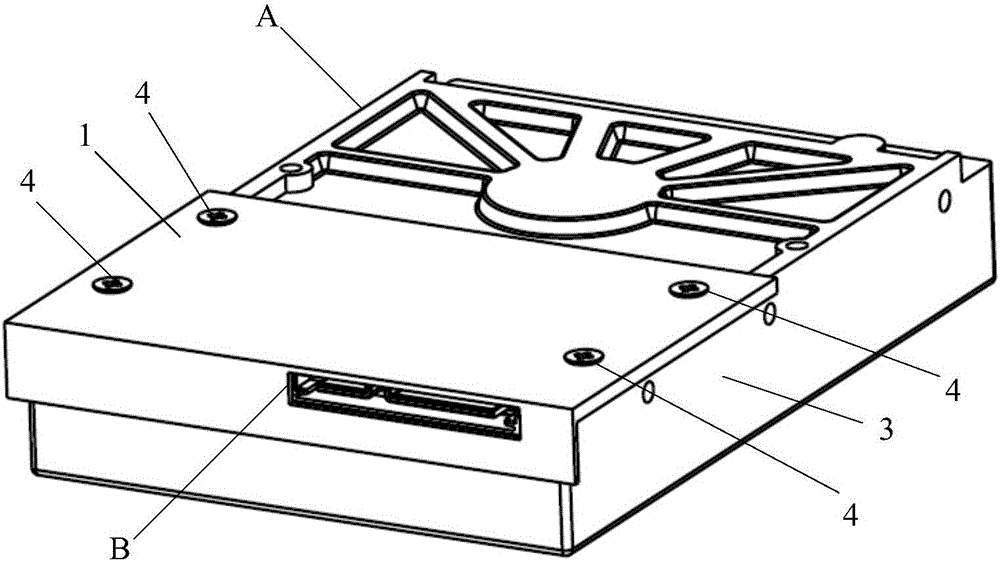

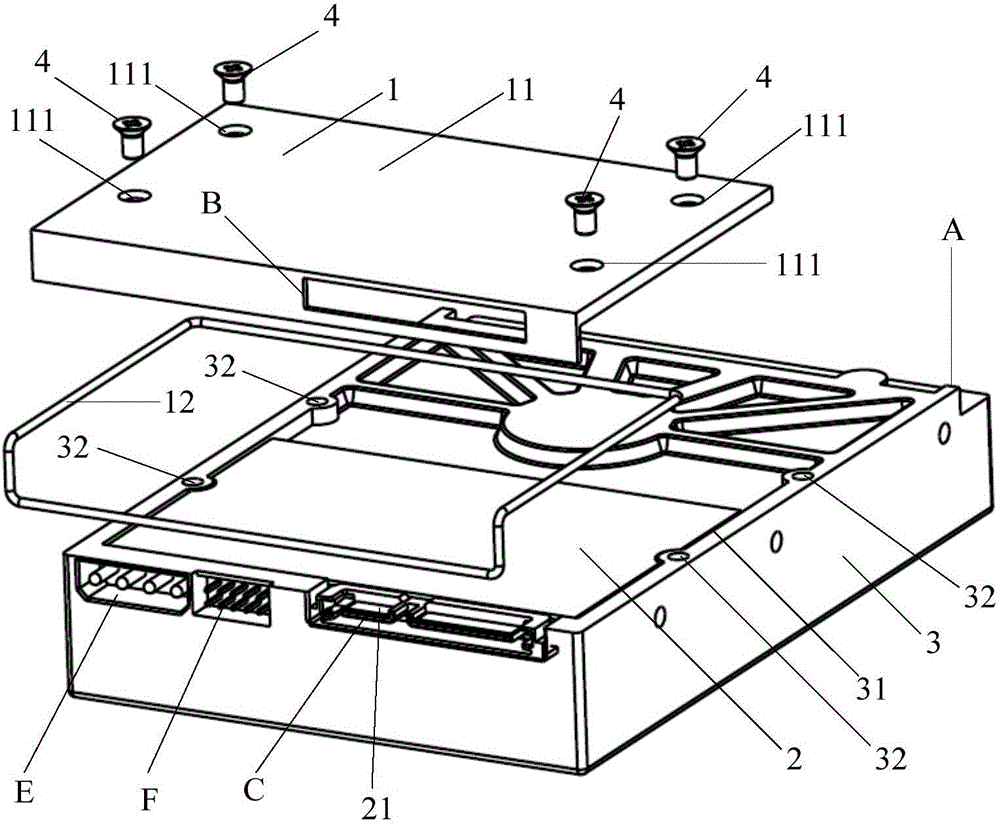

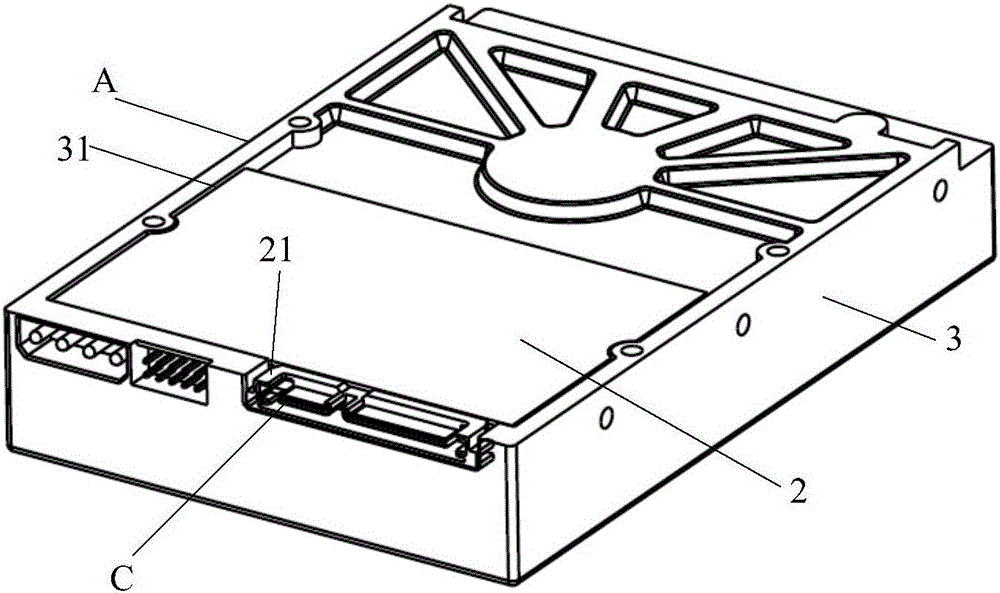

[0065] Such as figure 1 shown, and see figure 2 , the embodiment of the present invention provides a hard disk device A, the hard disk device A includes:

[0066] The sealing part 1, the printed circuit board 2 and the hard disk base 3, the surface of the sealing part 1 is provided with an opening B, and the surface of the hard disk base 3 is provided with a mounting groove 31;

[0067] The printed circuit board 2 is fixed in the installation groove 31 and electrically connected with the hard disk base 3, the sealing member 1 is covered on the installation groove 31, the printed circuit board 2 is located in the space formed by the sealing member 1 and the installation groove 31, printed The hard disk interface 21 on the circuit board 2 communicates with the outside world through the opening B, the hard disk interface 21 is in contact with the sealing member 1 and the contact position between the hard disk interface 21 and the sealing member 1 is sealed, so that the sealing ...

Embodiment 2

[0096] Such as Figure 10 As shown, some hard disk devices A need to be installed on the hard disk bracket D first, and then the hard disk device A with the hard disk bracket D installed is inserted into the device. For this type of hard disk device A, such as Figure 11 As shown, at this time, the sealing member 1 may include the following structure:

[0097] The cover plate 11, the second sealing body 14 and the hard disk bracket D, the surface of the cover plate 11 is provided with an opening B;

[0098] The hard disk base 3 is installed in the hard disk bracket D, the cover plate 11 is fixed on the hard disk bracket D and covers the installation groove 31, and the second sealing body 14 is located in the hard disk bracket D and is located on an edge inner wall of the cover plate 11 and the hard disk base. Between seats 3.

[0099] In the embodiment of the present invention, a hard disk bracket D is arranged on the sealing member 1, the hard disk device A is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com