Processing method of light vesuvianite-imitated paving block

A processing method and technology of volcanic stone, which is applied in the field of building decoration materials, can solve the problems of unreliable realization of hole adjustment, poor product consistency, and difficulty in stably realizing the distribution of pores with different pore sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

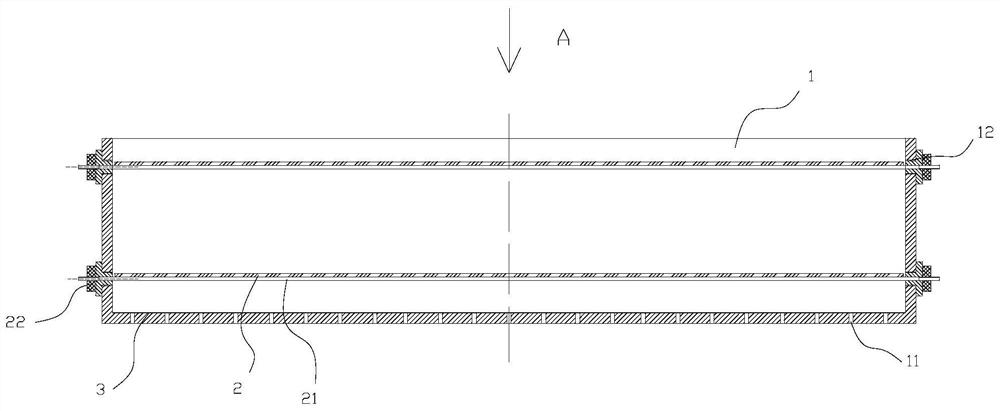

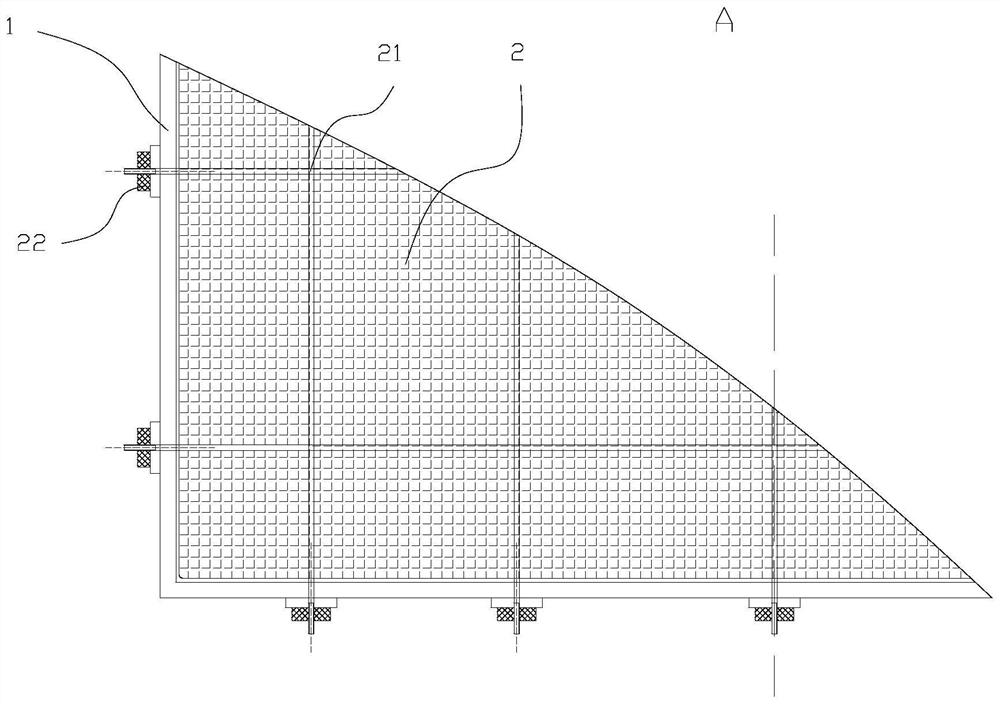

[0066] Embodiment one: if figure 1 , 2 , 4, the reinforcement layer 2 is a rigid mesh structure, and the support structure 21 is a well-shaped network structure composed of some intersecting support rods;

[0067] The connection assembly 22 includes a screw sleeve 221 and a parallel nut 222, the screw sleeve 221 is provided with an external thread, and a middle hole for accommodating the support rod;

[0068] The side wall of the lower mold 1 is provided with a connection hole 12 adapted to the external thread of the screw sleeve 221, and the screw sleeve 221 is connected to the outer side wall surface of the lower mold 1 through a thread structure; , and tighten the threaded section 211 out of the screw sleeve 221 , and the support rod is tightly connected to the screw sleeve 221 by the tightening nut 222 . The structure of the connecting assembly 22 is easy to operate, and can effectively "tighten" the support rod. After the initial setting, extend the two sides of the low...

Embodiment 2

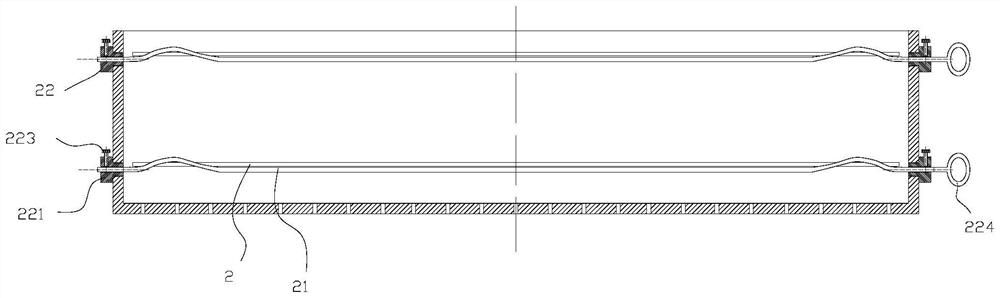

[0069] Embodiment two: if image 3 As shown, the reinforcement layer 2 is a flexible mesh structure (such as glass fiber mesh cloth, nylon fiber mesh cloth), and the support structure 21 is a well-shaped mesh structure composed of several intersecting support cables;

[0070] The connection assembly 22 includes a screw sleeve 221 and a locking screw 223, the screw sleeve 221 is provided with an external thread, and a middle hole for accommodating the support cable;

[0071] The side wall of the lower mold 1 is provided with a connection hole 12 adapted to the external thread of the screw sleeve 221, and the screw sleeve 221 is connected to the outer side wall surface of the lower mold 1 through a thread structure;

[0072] Steel wires or steel cables are used for the support cables, and even some polymer fiber ropes with high tensile strength can be used, and one end of the support cables is inserted into the middle hole, locked by the locking screw 223, and then transversely ...

Embodiment approach 1

[0078] Embodiment 1: Processing 80cm×80cm×15cm highway isolation belt ground pavement materials;

[0079] The porous matrix slurry includes the following components in parts by mass:

[0080] Cement: 60 parts by mass, mineral powder: 50 parts by mass, plasticizer: 0.5 parts by mass, and water: 41 parts by mass;

[0081] Add foam stabilizer 100g / m to it according to the volume to mass ratio 3 , pore-adjusting agent 1.5g / m 3 , and foaming agent, the amount of foaming agent added is calculated and quantified according to the design dry apparent density of the porous matrix;

[0082] After mixing cement, mineral micropowder, plasticizer and water evenly, add a certain amount of foam stabilizer and foaming agent, use forced high-speed stirring equipment, stir at a speed of 150 rpm, and control the stirring time to 12 seconds. Add a pore-adjusting agent at the 9th second of stirring, stop stirring when the stirring time reaches the predetermined time, and obtain a porous matrix s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com