Water dispenser liquid gravity energization control device

A control device and water dispenser technology, which is applied to beverage preparation devices, circuits, electric switches, etc., can solve the problems of high application cost, easy aging and failure of electronic components, etc., and achieve the effect of low application cost and stable and reliable control principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

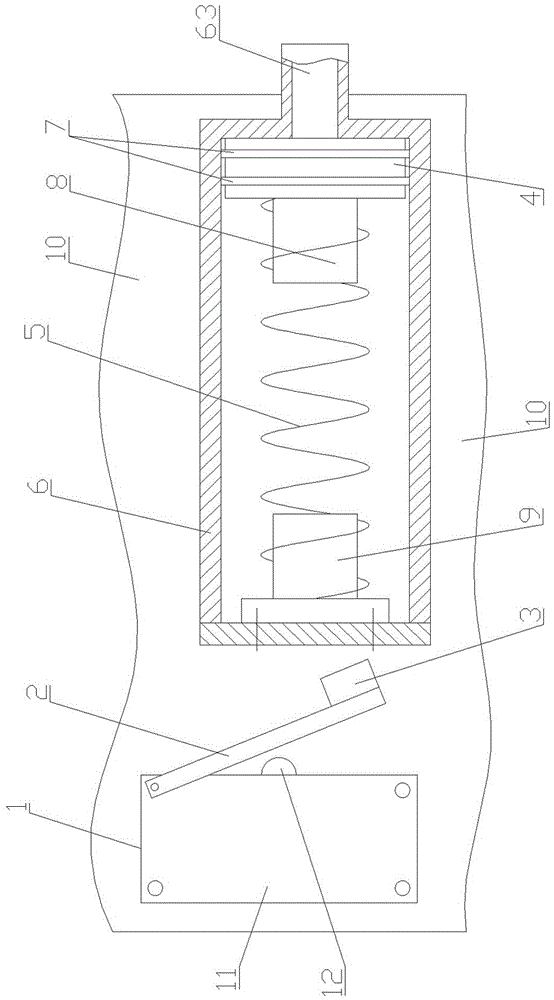

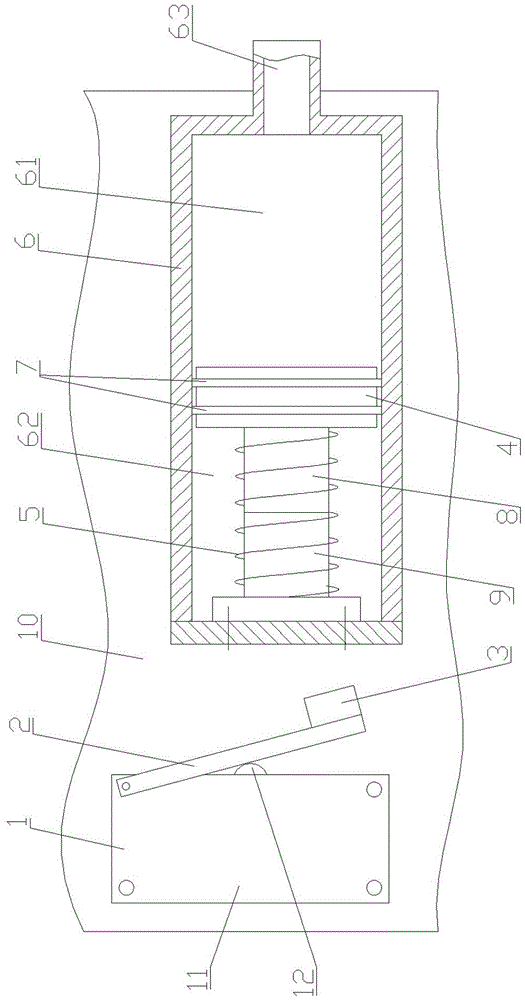

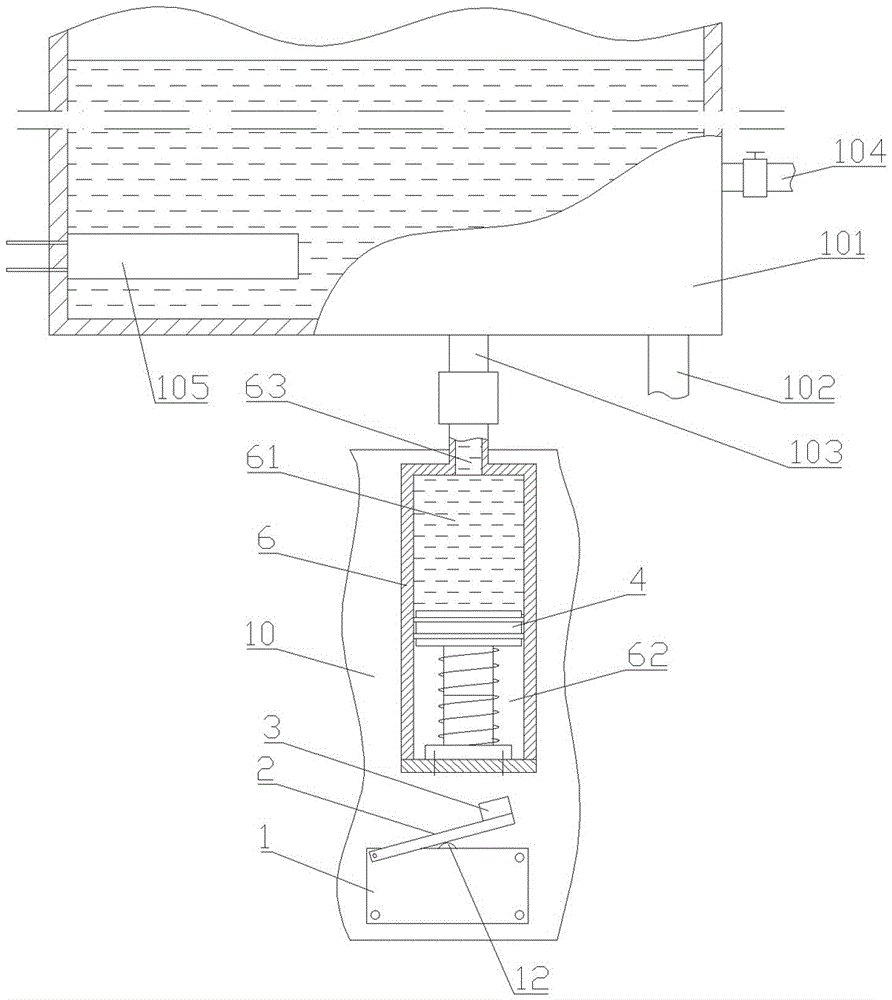

[0022] The water dispenser liquid gravity electrification control device includes a micro switch 1, a seesaw 2, an outer magnetic block 3, an inner magnetic block 4, an elastic element 5 and a cylinder body 6.

[0023] One end of the seesaw 2 is movably installed on the body 11 of the micro switch 1, and the other end is a free end. The contact 12 of the micro switch 1 is located at the lower end of the seesaw 2, and the seesaw 2 makes the contact 12 Toggles between open and closed. The outer magnetic block 3 is fixedly connected on the free end of the seesaw 2 and is opposite to the same magnetic pole of the inner magnetic block 4 . The inner magnetic block 4 is movably installed in the cylinder body 6, and it divides the inner chamber of the cylinder body 6 into chamber A61 and chamber B62 which are not connected to each other. The cylinder body 6 is provided with a liquid inlet 63 connected to the cavity A61. When the inner magnetic block 4 moves toward the outer magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com